You want high-end cosmetic bags like Estée Lauder, but your budget is tight. Sourcing premium packaging without breaking the bank feels impossible for many buyers.

To create Estée Lauder-style cosmetic bags on a budget, focus on minimalist designs using high-quality faux leather1 or polyester. Partner directly with experienced Chinese manufacturers2 who offer ODM services3. Use existing molds to save tooling costs and prioritize essential hardware to balance luxury aesthetics with affordability.

I have seen many buyers struggle with this balance. In my 15 years at Coraggio, I learned the secrets to affordable luxury. Let me show you how to do it.

How Can You Optimize Design and Materials for Lower Costs?

Complex designs eat up your profit margins quickly. You worry that cheaper materials will look bad and hurt your brand image.

Choose simple shapes and cost-effective materials like PU leather4 or polyester. Simplified printing and standard hardware5 reduce production time6 and material costs while maintaining a premium look.

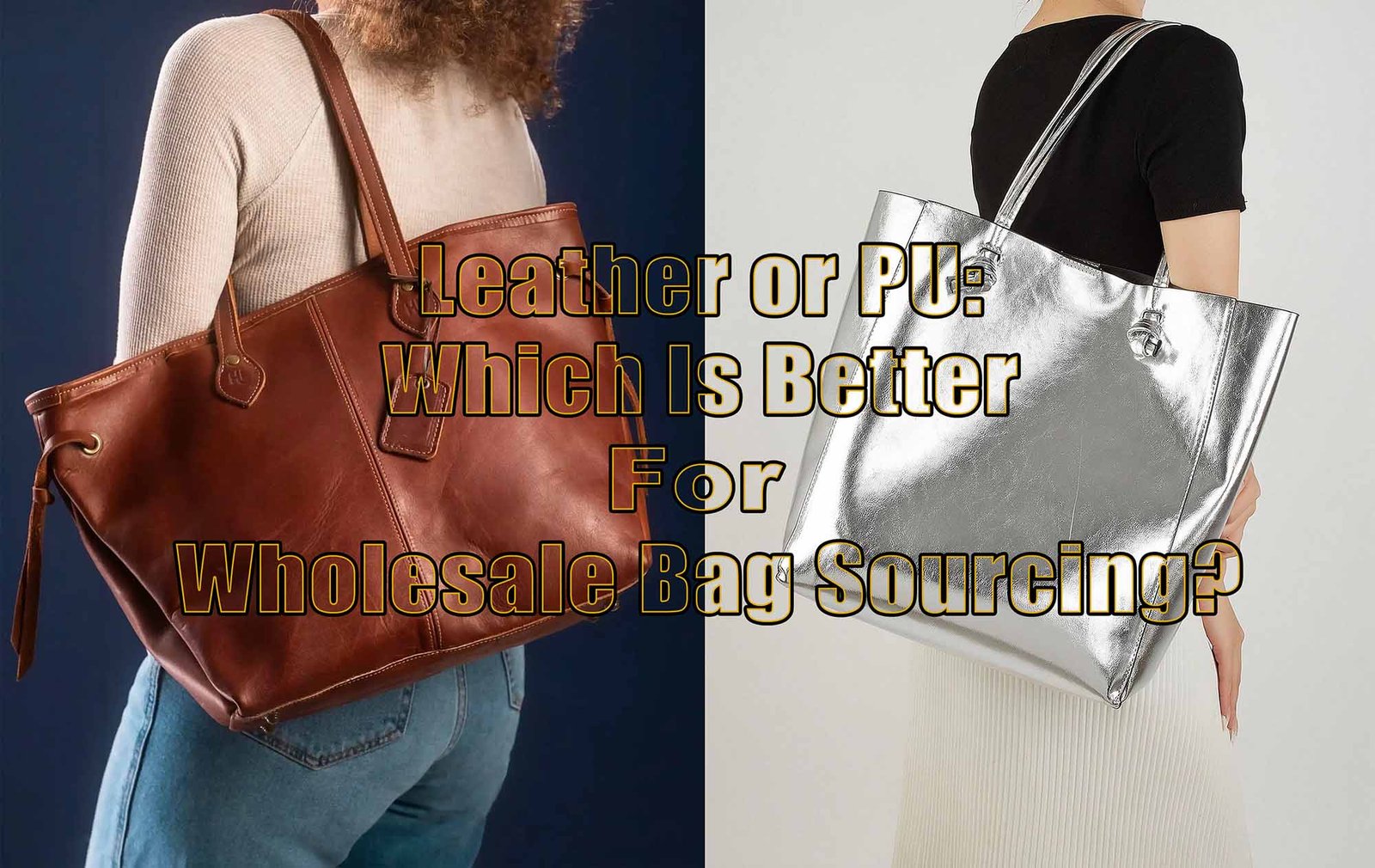

When you look at big brands like Estée Lauder, their bags are actually very simple. They rely on clean lines and one or two focal points. You do not need real leather to get this look. We can use high-quality PU (polyurethane) or even 600D polyester7. These materials are cheap but durable.

I remember a client from Canada. He wanted a complex bag with many pockets and real leather trim. The cost was $8 per unit. That was too high. I told him to switch to a high-grade PU leather4 that mimics the grain of real leather. We also removed the inside pockets that nobody sees. The price dropped to $2.50. The bag still looked expensive.

Also, think about your logo. Metal plates look nice, but they cost a lot. Embossing the logo8 directly onto the PU leather4 is free or very cheap. It looks elegant and subtle.

Here is a breakdown of how to swap expensive features for budget-friendly ones:

| Expensive Feature | Budget-Friendly Alternative | Why It Works |

|---|---|---|

| Real Leather | High-Quality PU / PVC | Looks the same, costs 80% less, easier to clean. |

| Metal Logo Plate | Embossed / Silk Screen Logo | No mold fee, lighter weight, classic look. |

| Custom Zipper Pull | Standard Zipper Pull | Function is the same, massive savings on molds. |

| Complex Shape | Square / Rectangular Shape | Less fabric waste during cutting, faster sewing. |

| Full Lining | Non-Woven Lining | Cheaper material inside, still protects contents. |

By making these changes, you lower the material cost. You also speed up the sewing process. Our 120 workers can finish simple bags much faster. This lowers the labor cost per unit.

Why Should You Rely on a Mature Supply Chain?

Finding a factory that understands your needs is frustrating. You often face high MOQ9s and expensive tooling fees for new custom molds.

Work directly with professional manufacturers in Chinese industrial hubs. Utilizing their existing molds for slight customizations eliminates tooling fees. A mature factory manages order sizes to lower your inventory risks.

You need a partner, not just a seller. In China, we have "industrial belts.10" These are areas where all the material suppliers and factories are close together. My factory is in one of these areas. This means I can buy zippers, fabric, and thread in the morning and start sewing in the afternoon. This speed saves you money.

Many buyers think they must design a bag from scratch. This is a mistake. We have over 15 years of experience. We have hundreds of existing molds. If you use our existing mold, you save $300 to $1,000 on tooling fees. You can still make it unique. You change the color. You change the fabric. You add your logo. But the structure remains the same. This is the ODM (Original Design Manufacturer) model.

I once worked with a buyer named Mark. He wanted a unique shape for a holiday promotion. The mold fee was high, and the delivery time was too long. I showed him a similar bag we made for a Japanese client. We just changed the zipper color to gold and used a shiny red fabric. He loved it. He saved money and got the bags two weeks early.

Here is how a mature supply chain11 helps your budget:

- Low MOQ9s: We can support smaller orders because we have raw materials in stock. You do not need to buy 10,000 bags at once.

- Fast Turnaround: Our 8 production lines are optimized. We do not waste time waiting for parts.

- Buying Power: We buy fabric in huge quantities. We get lower prices than you can get. We pass these savings to you.

- Technical Advice: My design team knows what works. We stop you from making expensive mistakes before production starts.

How Do Quality Control and Logistics Impact Your Final Price?

Poor quality leads to returns and destroys customer trust. You fear that cutting costs means receiving defective products that you cannot sell.

Define clear quality standards focused on durability and workmanship. Integrating production with logistics12 prevents delays. Good quality control13 prevents expensive rework and ensures you do not waste money on bad stock.

You might think quality control13 costs extra money. Actually, bad quality costs more. If you receive 1,000 bags and 200 have broken zippers, you lose money. You lose customers. You have to pay for shipping again.

At Coraggio, we focus on "Basic Quality." This means the bag must function perfectly. The zipper must slide smoothly. The stitching must be straight. The handle must not break. We might use cheaper fabric, but the sewing is always perfect. This is how you keep the "Estée Lauder" feel. A cheap bag with great sewing looks better than an expensive bag with bad sewing.

Logistics is another hidden cost. Bags are full of air. If you ship them fully assembled with paper stuffing, you are paying to ship air. This is very expensive for ocean freight. We design bags that can be packed flat. We remove the stuffing. We pack them tightly in the master carton.

I help my clients calculate the volume weight. For one client, we changed the packaging method. We put 50 bags in a carton instead of 20. His shipping cost per unit went down by $0.40. That is pure profit.

Here are the key checkpoints we use to balance quality and cost:

| QC Checkpoint | What We Look For | Cost Impact |

|---|---|---|

| Material Inspection | Check for holes or color differences before cutting. | Prevents wasting labor on bad fabric. |

| Inline Inspection | Check stitching during the sewing process. | Fixes errors immediately, avoiding rework. |

| Zipper Test | Open and close zipper 5 times. | Prevents returns due to functional failure. |

| Cleanliness | Remove loose threads and glue marks. | Makes the cheap bag look premium. |

| Packing | Flat pack with moisture protection. | Reduces shipping volume and prevents mold. |

We integrate these steps into our daily work. You get a reliable product without paying for unnecessary "luxury" inspection services. We act as your eyes in the factory.

Conclusion

To make luxury bags on a budget, use simple designs with good faux leather, use existing factory molds, and pack them flat to save shipping costs.

Explore the advantages of high-quality faux leather, which offers durability and a premium look at a fraction of the cost. ↩

Learn how to connect with skilled manufacturers in China who can help you create affordable luxury cosmetic bags. ↩

Understand how ODM services can streamline your production process and reduce costs significantly. ↩

Find out why PU leather is a popular choice for cosmetic bags, combining affordability with a luxurious appearance. ↩

Learn how using standard hardware can significantly reduce production costs while maintaining functionality. ↩

Discover strategies to streamline production time, leading to faster delivery and lower costs. ↩

Discover why 600D polyester is a cost-effective, durable material for luxury cosmetic bags, offering a premium look without the high price tag. ↩

Embossing logos offers a cost-effective way to enhance brand visibility while maintaining an elegant look, saving on mold fees and adding subtle sophistication. ↩

Understanding low MOQ benefits helps you manage inventory risks and reduce upfront costs, crucial for small businesses aiming for affordable luxury. ↩

Industrial belts in China streamline production by clustering suppliers and factories, reducing costs and speeding up manufacturing processes. ↩

Understand the advantages of a mature supply chain in reducing costs and improving efficiency in production. ↩

Learn how effective logistics can reduce shipping costs and improve overall profitability in bag production. ↩

Discover essential quality control practices that ensure your bags meet high standards without excessive costs. ↩