Fashion trends change overnight, leaving warehouses full of unsold bags. If your supply chain is slow, you lose money. Here is how to fix it.

To adapt to fast trends, bag brands must shift to a "Fast Reaction Mode1." This involves partnering with agile factories2 for quick sampling, using small-batch testing3 to validate designs before mass production, and utilizing modular designs4 to iterate styles rapidly without rebuilding the entire production line.

Many buyers I talk to feel stuck. They see a trend, but by the time their goods arrive, the trend is gone. I have seen this happen too often in my 15 years of manufacturing. But there is a better way to manage production.

Why Do Traditional Bag Supply Chains Struggle With Fast Trends?

You see a new style on TikTok, but your factory takes three months to deliver. Why is the old system failing you now?

Traditional supply chains rely on massive minimum order quantities (MOQs)5 and long lead times6. They focus on cost reduction through volume, not speed. This rigidity makes it impossible to pivot quickly when consumer preferences shift, resulting in high inventory risk7.

In my experience running Coraggio, I see the problem clearly. Traditional factories are like big ships. They take a long time to turn. They are built for stability, not speed. When you ask for a change, they have to stop a whole line. This costs money. So, they demand high MOQs to cover that cost. This model worked ten years ago. It does not work today.

We see this often with buyers from large companies. They move too slow. The rigid process creates a bottleneck. They order fabric months in advance. Then the market changes. They are left with thousands of bags that no one wants.

Here is a simple breakdown of the old way versus the new reality:

| Feature | Traditional Supply Chain | Fast Trend Supply Chain |

|---|---|---|

| Order Size | Large (10,000+ pcs) | Small (300-500 pcs) |

| Lead Time | 60-90 Days | 15-30 Days |

| Design Focus | Cost efficiency | Speed to market |

| Risk | High (Dead stock) | Low (Test first) |

The traditional model puts all the risk on you. You pay for the goods before you know if they will sell. You need a system that shares the pressure and moves faster.

How Can Bag Brands Use Small-Batch Testing to Reduce Trend Risk?

Betting your whole budget on one unproven design is dangerous. You need a safer way to check if customers actually want the bag.

Small-batch testing allows you to produce a limited quantity of a new design first. You sell these to test the market reaction. If the data is good, you quickly place a larger reorder. This strategy minimizes financial loss on unpopular styles.

I always tell my clients to test before they invest. Imagine you see a new neon color trend. Do not order a full container. Ask us for a trial order8. We have 8 production lines9, so we can handle this flexibility. You put the bags online or in a few stores. Watch the sales data. If it sells out in a week, you call me. We then rush the mass production.

This is the "Fast Reaction Mode1" we use with smart clients. It saves money. You only pay for what works. This method requires a factory that supports low MOQs initially. Not every factory will do this. Many want the easy, big orders. But a good partner understands the long-term value of your growth.

You need to establish a specific workflow for this:

- Quick Sample: We make the sample in 3-5 days.

- Trial Order: You order 300 pieces.

- Market Test: You sell them for two weeks.

- Analysis: You check the sales numbers.

- Replenishment: We produce the big order immediately if numbers are good.

This cycle turns your supply chain into a safety net10. You stop guessing and start using data to make purchasing decisions.

How Does Modular Design Help Speed Up New Bag Launches?

Designing a bag from scratch takes weeks. What if you could change just one part to create a totally new look?

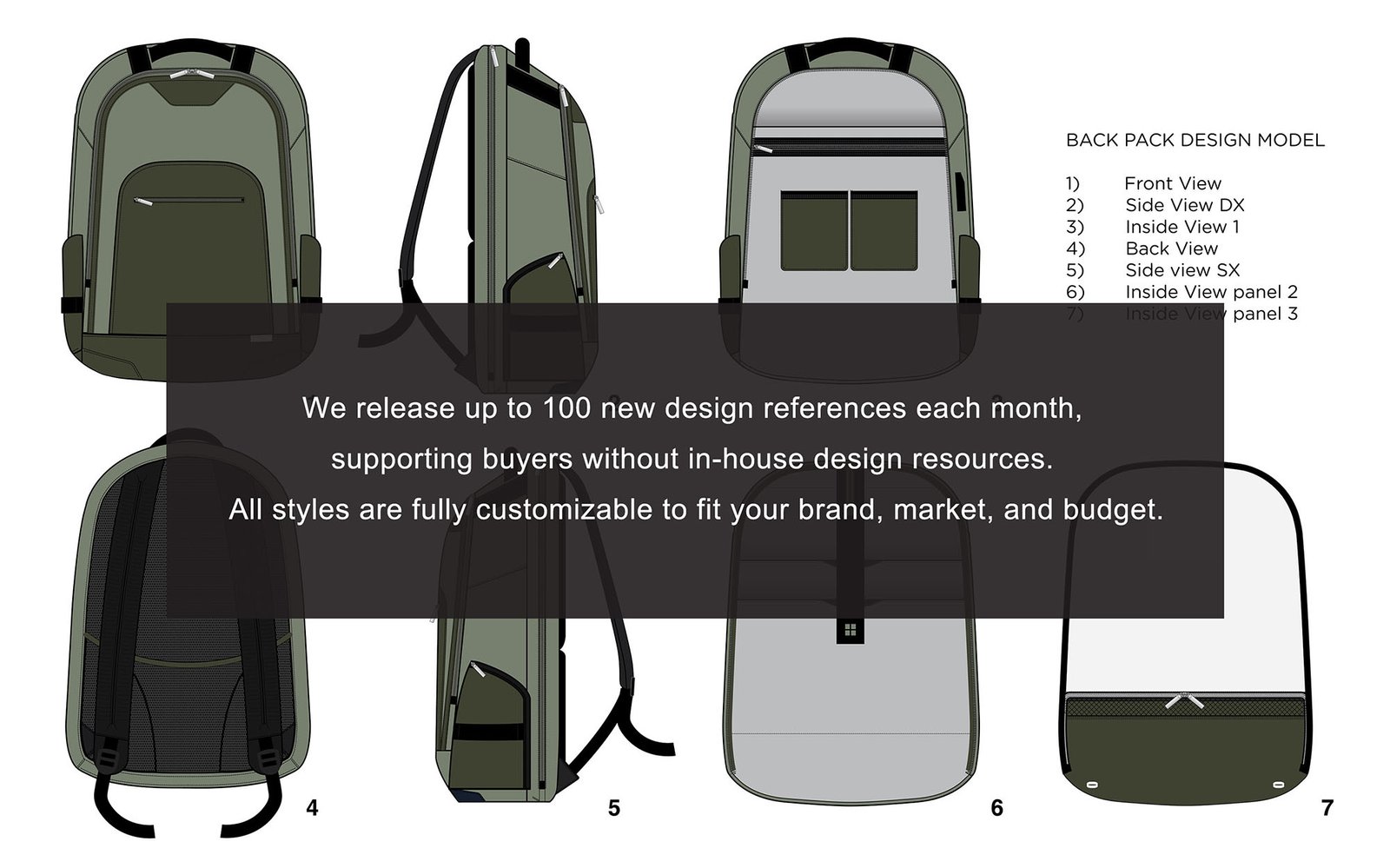

Modular design involves keeping the main structure of the bag constant while changing specific elements like fabrics, pockets, or hardware. This reduces development time because the core pattern is already tested and ready for production, allowing for rapid style updates.

At Coraggio, our design team11 uses modular thinking. We keep the base pattern of a popular backpack. We know it fits well. We know it is strong. To follow a trend, we just change the front panel material. Maybe we use velvet in winter and mesh in summer. We can also swap the zippers or handles.

This saves the time needed for making new paper patterns. We do not have to test the load-bearing capacity again. It is already proven. This cuts the sample making time in half. You get the product to market faster. Your customers see something new, but your production risk stays low. It is a smart way to manage SKU diversity without chaos.

Here is how we break down a bag for modular design:

- The Skeleton: This is the main body shape. We keep this the same to save engineering time.

- The Skin: This is the main fabric. We change this to match the season's color trend.

- The Face: These are the pockets and flaps. We can change the shape of a pocket to make the bag look sporty or elegant.

- The Hardware: Zippers and buckles. Changing these from silver to gold changes the whole price perception.

By mixing these parts, we can create ten different styles from one production setup. This is how you keep your catalog fresh without spending a fortune on development.

What Factory Capabilities Matter Most for Fast-Reaction Production?

Not all manufacturers can handle speed. You need to look for specific traits in a supplier to ensure they can keep up.

You need a factory with stable material resources12, an in-house design team11, and flexible production lines9. They must have strong control over their sub-suppliers to ensure raw materials arrive on time, preventing delays that kill fast-fashion schedules.

When you look for a supplier in China or Vietnam, do not just look at the price. Look at their resources. Do they have their own material warehouse? If they have to buy every zipper from a market, they will be slow. I keep common fabrics in stock at our 3,000 square meter facility. This means we can start cutting immediately.

Also, look at their sample room. We have 10 designers. We can turn a sketch into a bag in 3 days. A trading company cannot do this. They have to wait for a factory. Direct factory control is the key. You need a partner who owns the process. This guarantees that your "rush order" is actually rushed, not just added to a list.

You should ask potential suppliers these questions:

- Do you have an in-house design team11? This speeds up the changes you need.

- Do you have stock materials? This cuts weeks off the lead time.

- How many production lines9 do you have? We have 8 lines and 120 workers. This lets us shift workers to urgent orders.

- Can you do OEM and ODM13? You need a factory that can design for you, not just copy.

If a factory cannot answer these clearly, they will likely delay your order. Speed comes from capability, not just promises.

How Can Brands Improve Supply Chain Visibility and Delivery Control?

You place an order and then hear nothing for weeks. This silence is scary when you have a launch date to meet.

Brands must demand real-time updates14 and clear milestones from their suppliers. Improving visibility means setting agreed-upon checkpoints for material arrival, cutting, sewing, and final QC. This allows you to spot potential delays early and solve them before they become disasters.

Mark, a buyer from Canada, told me his biggest headache is silence. He emails a supplier and waits three days for a reply. In the fast trend game, this is fatal. You need to know where your order is. We use a transparent schedule. We tell you when the fabric arrives. We tell you when the cutting starts.

If there is a delay, we tell you immediately. We do not hide it. We fix it. For example, if a zipper supplier is late, we find a backup instantly. You need this level of control. It builds trust. You can plan your marketing because you know exactly when the goods will hit your warehouse. Real control comes from open communication and strict quality checks15 at every stage.

We suggest using a simple tracking sheet16 shared between you and the factory. It should list:

- Material Arrival Date: The day the fabric is in the factory.

- Pre-production Sample Approval: The day you say "go."

- Cutting Completion: When the fabric is cut.

- Sewing Progress: Weekly updates (e.g., 50% done).

- Inspection Date: When our QC checks the final goods.

When you see these dates, you feel safe. You can sleep at night. You know your products will arrive on time to catch the trend.

Conclusion

To catch fast trends, use small batches, modular design, and an agile factory. This reduces risk and keeps your brand relevant. Speed is your new competitive advantage.

Explore how Fast Reaction Mode can transform your supply chain for quicker responses to trends. ↩

Learn about the benefits of agile factories in adapting to fast-changing market demands. ↩

Discover how small-batch testing can minimize financial risks and validate designs effectively. ↩

Understand how modular designs can speed up product launches and reduce development time. ↩

Find out how MOQs impact supply chain flexibility and cost efficiency. ↩

Get insights into how lead times affect production schedules and market responsiveness. ↩

Learn about the factors contributing to inventory risk and how to mitigate them. ↩

Explore the concept of trial orders and how they can help test market demand. ↩

Understand the role of production lines in enhancing manufacturing efficiency and speed. ↩

Discover how creating a safety net can protect your business from supply chain disruptions. ↩

Understand the importance of having an in-house design team for faster product development. ↩

Learn how stable material resources can enhance production efficiency and reduce delays. ↩

Learn about OEM and ODM services and how they can benefit your product development. ↩

Explore the importance of real-time updates in maintaining control over your supply chain. ↩

Learn about the significance of quality checks in ensuring product standards. ↩

Explore how a tracking sheet can improve communication and transparency in your supply chain. ↩