Do you wonder why some free cosmetic bags feel cheap while others feel luxurious? You are not alone in wanting to know the secret behind high-end gifts.

A high-quality Lancôme GWP bag1 combines premium materials2 like faux leather and heavy canvas with precise craftsmanship. Strict quality control3 ensures durability, while large-scale manufacturing keeps costs low without sacrificing standards. This balance creates a premium feel that enhances brand value.

Many buyers believe that "free" means low quality. However, big brands like Lancôme prove this wrong every day. In my 15 years running a bag factory in China, I have seen exactly how they do it. I have worked with many clients who want that "Lancôme feel" for their own promotional items. It is not magic; it is a specific manufacturing approach. Let me show you the specific details.

How Do Materials and Hardware Define the Luxury Feel?

You pick up a bag, and your fingers tell you the price immediately. Poor fabric ruins the experience before you even open the zipper.

High-quality GWP bags use materials that mimic luxury goods, such as textured PU leather4 or high-density canvas5. Combined with gold-stamped logos6 and smooth, heavy zippers, these elements create a tactile experience that feels expensive despite being a gift.

When we talk about the "feel" of a bag, we are talking about material selection. In my factory, we often advise clients against using thin, noisy nylon if they want to impress a customer. Lancôme understands this very well. They are willing to use good materials. Even though these bags are gifts, they often use simulation leather (PU) or thick canvas.

For example, a standard promotional bag might use 600D polyester. It feels stiff and plastic. But a high-end GWP bag will use 12oz cotton canvas7 or a soft-touch PU leather4 with a grain texture. When you touch it, it feels substantial. It does not feel like a throw-away item. I remember a time when a buyer from Europe wanted to cut costs by 10 cents. He wanted to switch from a metal zipper puller8 to a plastic one. I told him, "This will make your $50 gift set look like it costs $5." He kept the metal.

The details matter immensely. Look at the logo. A cheap bag has a screen print that might peel off. A quality bag uses hot stamping9 (gold or silver foil) or an embossed logo10. This looks elegant. The hardware, like the zipper head, is often polished gold or silver tone. It shines. It slides smoothly without getting stuck. These material choices send a message to the user: "We value you."

Here is a breakdown of the material differences:

| Feature | Standard GWP Bag | High-End (Lancôme Style) GWP | Impact on Customer |

|---|---|---|---|

| Main Material | Thin Polyester / Non-woven | PU Leather / Heavy Canvas / Velvet | Feels durable and expensive. |

| Logo Method | Simple Screen Print | Embossing / Gold Foil Stamping / Metal Plate | looks prestigious and lasts longer. |

| Zipper | #3 Nylon Coil, Plastic Puller | #5 Metal or Nylon with Metal Puller | Operates smoothly, adds weight. |

| Lining | None or thin taffeta | Polyester Satin or branded lining | Provides a finished, clean interior. |

Why Is Strict Quality Control Essential for Durability?

A beautiful bag is useless if the strap breaks on the first day. Weak stitching destroys your brand reputation faster than anything else.

Strict quality control3 means every bag undergoes standardized checks. Straight stitching, reinforced stress points11, and flat, smooth linings are non-negotiable. This attention to detail ensures the bag is practical and durable, serving as a long-lasting reminder of the brand.

You might have a great design and great materials, but execution is everything. In our 3,000 square meter facility, we have strict rules. This is the second secret to high quality: strict management and detailed production. A brand like Lancôme does not tolerate sloppy work.

When we produce orders for high-end clients, we set up a "Golden Sample12." This is the perfect bag that every other bag must match. I tell my 120 workers, "If it does not look like this, do not pack it."

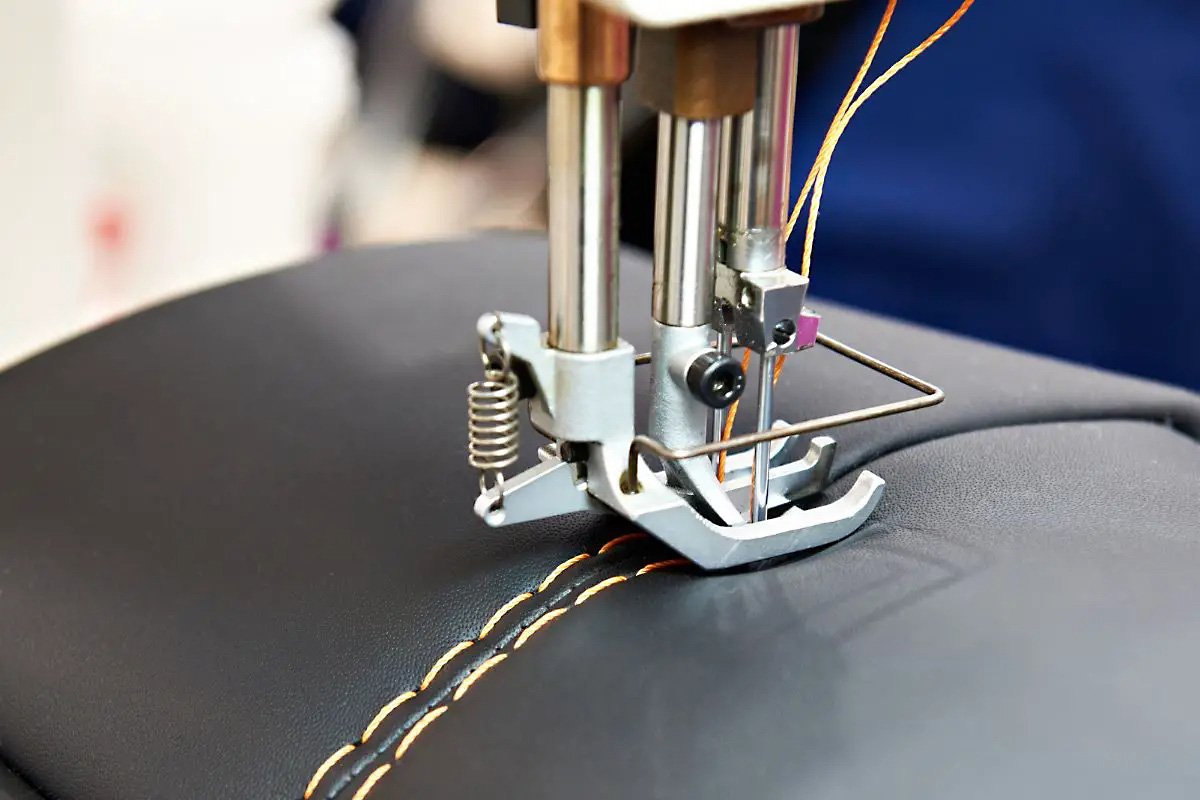

One major area is the stitching. The lines must be perfectly straight. There should be no loose threads hanging out. We call this "trimming." In cheaper factories, workers rush. They leave long threads inside the bag. When the customer opens it, it looks messy. In high-quality production, we burn or trim every loose end.

Another critical point is the lining. Have you ever opened a cosmetic bag and the lining is too big? It bunches up and looks wrinkled. Or it is too small and pulls the outer fabric? That is poor pattern making. A quality bag has a lining that fits flat and smooth. It feels solid. We also reinforce the stress points11. If you fill a cosmetic bag with heavy lotion bottles, the handle must not rip. We use back-stitching at these points to make them strong.

We can break down the quality control3 process into these steps:

- Incoming Material Check: We inspect the fabric rolls before we even cut them. We look for color differences or scratches.

- In-Line Inspection: During sewing, QC managers walk the lines. They check the stitch length (SPI - Stitches Per Inch). High quality usually requires 7-8 stitches per inch.

- Finished Product Check: Every single bag is inspected. We check the zipper function, the logo position, and the shape.

- Needle Detection: This is vital for safety. We pass bags through a machine to ensure no broken needles are left inside.

This rigorous process ensures that the bag is not just a pretty wrapper. It is a functional product that the customer will use for travel or daily storage for years.

How Can Brands Balance Low Cost with High Quality?

You might think high quality always requires a high budget. But smart buyers know that volume and strategy can lower prices significantly.

Brands achieve low unit costs through massive order volumes and long-term partnerships with mature OEM factories. This allows for bulk material purchasing and streamlined production lines, keeping the price low while maintaining strict quality standards for effective marketing.

This is the part that interests buyers like Mark Porter the most. How can a bag look so expensive but cost the brand so little? The answer is smart cost control, not cheap manufacturing.

Brands like Lancôme do not order 500 bags. They order 50,000 or 100,000 bags at a time. When you order this quantity, the economics change completely. As a factory owner, I can buy raw materials directly from the fabric mill at a huge discount. I do not buy from a middleman market. This saves 20% to 30% on material costs immediately.

Also, mature factories like ours are efficient. We have 8 production lines. When we set up a line for a massive order, the workers get into a rhythm. They become faster and make fewer mistakes. This efficiency lowers the labor cost per unit.

There is also a strategic mindset. These bags are "Moving Advertisements." The brand views the cost as a marketing expense. They want the bag to last a long time so the customer sees the logo every day. Therefore, they invest in a mature factory that can deliver consistent quality. They do not jump to the cheapest, smallest workshop. They know that a 5% saving is not worth the risk of a quality disaster.

We also help clients with "Value Engineering13." If a design is too expensive, my design team (10 people) will suggest changes that keep the look but lower the cost. For example, instead of a complex metal mold for a logo, we might suggest a high-quality rubber patch that looks similar but costs less.

Here is how volume impacts the final price and quality:

| Cost Factor | Small Order (500 pcs) | Large Order (50,000 pcs) | Why it Matters |

|---|---|---|---|

| Material Sourcing | Retail Market Price | Factory Direct Price | Lower material cost allows better quality fabric for the same budget. |

| Production Efficiency | High Setup Time / Slower | Optimized Assembly Line | Lower labor cost per unit. |

| Customization | Limited options | Full Customization | Can create custom molds and colors without extra fees. |

| Shipping | LCL (Less than Container) | FCL (Full Container Load) | Much cheaper logistics cost14 per bag. |

By using these strategies, a brand can pay a low price—perhaps only a few dollars—for a bag that would sell for $20 or $30 in a retail store.

Conclusion

Lancôme cosmetic bags achieve high quality through premium material selection, rigorous manufacturing standards, and the economic power of mass production15. These elements create a valuable, durable gift that strengthens customer loyalty16.

Explore the craftsmanship and materials that elevate Lancôme's GWP bags to luxury status. ↩

Discover the types of materials that contribute to the luxurious feel of cosmetic bags. ↩

Learn how strict quality control ensures durability and enhances brand reputation. ↩

Explore the advantages of PU leather in creating high-quality, affordable bags. ↩

Understand the benefits of high-density canvas in creating durable and luxurious bags. ↩

Find out how gold-stamped logos add a touch of elegance to cosmetic bags. ↩

Discover why 12oz cotton canvas is preferred for luxury bags, offering durability and a premium feel that enhances brand value and customer satisfaction. ↩

Discover how metal zipper pullers enhance the functionality and feel of bags. ↩

Hot stamping adds elegance and durability to logos, enhancing brand prestige and longevity on cosmetic bags. Discover its impact on quality. ↩

Learn why embossed logos are a sign of quality in luxury products. ↩

Understand the importance of reinforcing stress points for durability in bags. ↩

Learn about the Golden Sample process that ensures consistent quality in production. ↩

Explore how Value Engineering helps maintain quality while reducing costs. ↩

Understand the role of logistics in determining the final price of manufactured goods. ↩

Learn how mass production can lower costs while maintaining high quality. ↩

Explore the connection between quality gifts and building lasting customer relationships. ↩