Sourcing eco-friendly bags is difficult because there are many fake products in the market today. If you buy the wrong "green" bags, you lose money and damage your brand reputation.

To source recycled bags safely, ask suppliers for GRS transaction certificates1, verify fabric origin (RPET or Nylon)2, and confirm physical testing standards like tear strength3. This ensures you get genuine eco-friendly products that meet US and EU compliance laws while maintaining durability and profit margins.

I have seen many buyers from Europe and North America make mistakes with recycled materials. They trust a simple picture of a certificate, but they do not check the details. At Coraggio, I have spent 15 years manufacturing bags. I know that recycled fabric behaves differently than virgin fabric. You must ask the right questions to protect your business.

Which Recycled Fabrics Are You Using?

Many suppliers say "recycled," but they do not tell you what the specific material is. This is a problem because different materials have different costs and uses.

You must ask if they use post-consumer RPET (from plastic bottles)4 or pre-consumer recycled nylon5. RPET is cheaper and great for tote bags, while recycled nylon is stronger and better for premium backpacks.

Dive Deeper

You need to understand the material before you ask for a price. In my factory, we use different recycled fabrics for different products. If you do not specify the material, a bad supplier might give you the cheapest option that does not fit your market.

Here is how I break down the options for my clients:

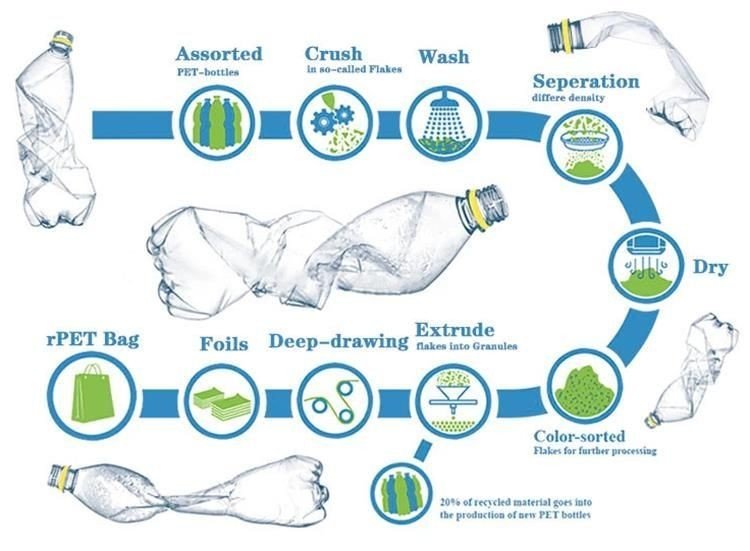

- RPET (Recycled Polyethylene Terephthalate): This is the most common material. It comes from old plastic water bottles. We crush the bottles, melt them, and turn them into yarn. It is very good for cosmetic bags, cooler bags, and shopping totes. It is usually 10% to 20% more expensive than normal polyester, but the price gap is getting smaller.

- Recycled Nylon: This comes from fishing nets or industrial waste. It is much stronger than RPET. However, it is much more expensive. If you sell high-end outdoor backpacks, this is a good choice.

- Recycled Cotton: This comes from cutting scraps in garment factories. It often looks more natural and has a soft feel.

When I talk to a new customer, I always ask them about their target price. If they want a very low price, I suggest 600D RPET6. If they want a luxury feel, I suggest Recycled Nylon. You must match the fabric to your product type.

| Material Type | Source | Best Application | Cost Level |

|---|---|---|---|

| RPET Polyester | Plastic Bottles | Totes, Coolers, Basic Backpacks | Low/Medium |

| Recycled Nylon | Fishing Nets/Industrial | Heavy Duty Backpacks, Luggage | High |

| Recycled Cotton | Factory Scraps | Promotional Bags, Shoppers | Medium |

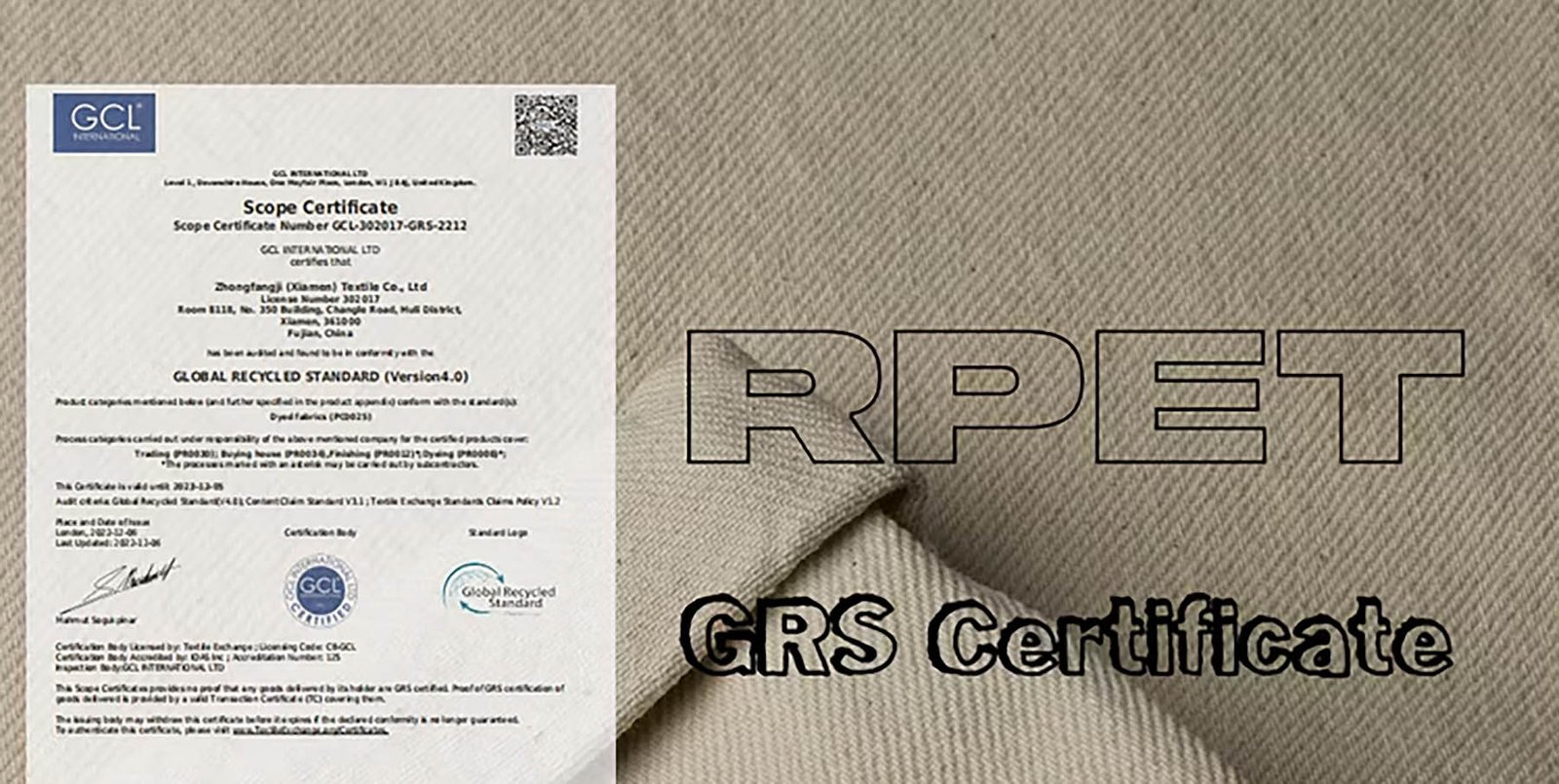

What Proof of Recycled Content Can You Provide?

A supplier can easily lie and say a bag is recycled when it is actually virgin polyester. You cannot see the difference with your eyes.

Demand a valid Global Recycled Standard (GRS) Scope Certificate7 and a Transaction Certificate (TC) for your specific order8. The TC is the only way to prove the fabric in your specific shipment is actually recycled.

Dive Deeper

This is the most critical part of sourcing recycled bags. Many buyers send me a "certificate" from another factory and ask if it is real. Often, it is fake or expired.

You need to ask for two documents:

- Scope Certificate (SC): This proves the factory is allowed to make recycled products. It shows they passed the audit.

- Transaction Certificate (TC): This is like a bank receipt for materials. It proves that X amount of recycled yarn was bought for your specific order.

If a supplier says, "We have the certificate, but we cannot give you a TC for this order," be careful. This usually means they are buying normal fabric but using a borrowed certificate to fool you.

At Coraggio, we apply for a TC for every order if the customer requests it. The GRS system tracks the material from the recycling plant to the yarn spinner, then to the fabric mill, and finally to my bag factory. If any link in this chain breaks, you cannot get a TC.

Checklist for verifying documents:

- Check the expiration date on the Scope Certificate.

- Check the company name. It must match the supplier's name.

- Check the product category. It must say "Fabrics" or "Bags."

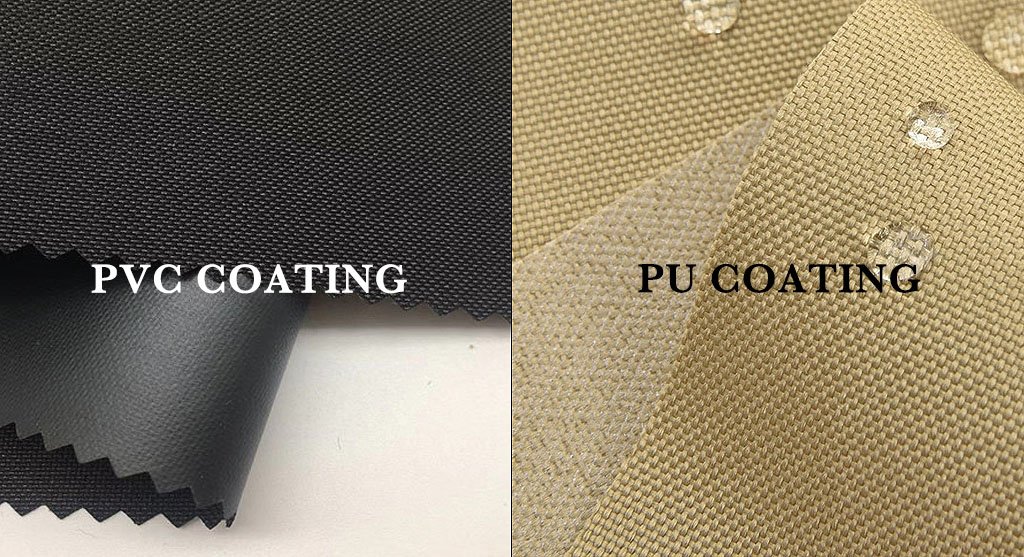

What Fabric Specs Matter for Bags?

Recycled fibers can sometimes be shorter or weaker than virgin fibers. If you do not check the specs, the bag might rip.

Focus on the coating backing (PU or PVC)9, the yarn count (600D vs 900D), and the tear strength10. Recycled fibers can be weaker, so a strong backing is crucial for structure and water resistance.

Dive Deeper

When we make bags from recycled bottles, the plastic has been melted and reformed. Sometimes, this process reduces the strength of the fiber slightly. To fix this, we need to pay attention to the "backing."

The backing is the layer of glue or plastic on the back of the fabric.

- PU (Polyurethane) Backing: This is soft and light. We use it for backpacks that need to be flexible.

- PVC (Polyvinyl Chloride) Backing: This is thick and stiff. We use it for bags that need to stand up on their own, like some cooler bags.

I always tell my procurement team to test the "tear strength10." We use a machine to pull the fabric until it rips. For a good backpack, the fabric should withstand at least 80KG of force.

Also, ask about "color fastness11." Recycled polyester can have trouble holding dye if the water bottles were not cleaned perfectly. We test to make sure the color does not rub off onto your customer's white shirt.

Key Specs to Ask For:

- Weight: Measured in GSM (grams per square meter). Heavier is usually stronger.

- Density: Measured in D (Denier). 600D is standard; 1680D is heavy duty.

- Water Pressure12: Can it stop rain? Ask for 1000mm water resistance.

How Do You Control Quality Risks?

Recycled fabric often has more quality issues than virgin fabric. The biggest problem is color variation between different rolls of fabric.

Ask about their Greige storage and dyeing process13. Suppliers must use consistent master batches and perform inline inspections to ensure the grey fabric absorbs color evenly before they cut the material.

Dive Deeper

In my 15 years of experience, the biggest headache with recycled fabric is "impurities." When you recycle plastic, sometimes there are small bits of other materials left inside. When we dye the fabric, these impurities do not accept the color. This creates small spots or streaks.

Another problem is "lot variation." If I buy recycled fabric today, and then I buy more next month, the color might look slightly different. The base material (the bottles) changes.

To control this risk, I use a strict process at Coraggio:

- One Batch Purchase: We calculate the total fabric needed for your order and buy the yarn in one single batch. We do not buy in small pieces.

- Light Box Testing: We check the color under different lights (D65 daylight, store light, etc.) to match your sample.

- 100% Inspection: My workers unroll the fabric and look for black spots or holes before we cut it. If we find a bad spot, we cut it out and throw it away.

You should ask your supplier: "What is your rejection rate for recycled fabric?" If they say "0%," they are lying. Real recycled fabric always has some waste. We usually budget 3% to 5% extra material to cover these defects.

What Are the MOQ, Lead Time, and Cost Drivers for Recycled Fabric Bags?

You need to know how these eco-friendly materials affect your budget and your schedule. It is different from standard production.

Recycled fabric usually has higher MOQs (often 1000+ yards) because factories cannot buy small scrap lots effectively. Lead times are longer because GRS certification takes extra time to issue after production.

Dive Deeper

Business is about profit and timing. Recycled bags affect both.

Cost: Recycled fabric is more expensive because the process is complex. Collecting bottles, cleaning them, and melting them costs money. Usually, a recycled bag costs $0.50 to $1.50 more than a normal bag, depending on the size. You need to account for this in your retail price.

MOQ (Minimum Order Quantity14): Fabric mills do not like to run their machines for small amounts of recycled yarn. It is inefficient.

- For standard colors (Black, Navy, Grey): We can often do smaller orders, like 500 bags, because we have stock.

- For custom PMS colors: The MOQ is high. The fabric mill might require 3,000 yards. This means you might need to order 2,000 to 3,000 bags.

Lead Time: This is very important. The production time for the bags is the same (about 30-45 days). However, getting the GRS Transaction Certificate (TC) takes extra time15. The certifier audits the production after it is finished. Sometimes, the TC arrives 2 or 3 weeks after we ship the goods. You need to tell your marketing team about this delay.

| Factor | Standard Bag | Recycled Bag |

|---|---|---|

| Fabric Cost | Base Price | +15% to +25% |

| Custom Color MOQ | 1,000 yards | 3,000 yards |

| Document Lead Time | Immediate | +2-4 Weeks for TC |

Can You Support Compliance for US/EU Markets?

Just because a bag is "recycled" does not mean it is safe. It must still pass chemical laws in your country.

Confirm the fabric passes REACH (Europe)16 or CA Prop 65 (USA) testing17. Recycled plastics can sometimes carry legacy chemicals from their previous life, so lab testing is mandatory.

Dive Deeper

Many buyers forget this step. They think "Eco-friendly" means "Safe." This is not always true.

Recycled plastic comes from waste. We do not always know exactly what was in that plastic before. Sometimes, old plastics contain heavy metals or phthalates that are now banned.

If you export to Europe, you must pass REACH. This checks for hundreds of harmful chemicals. If you export to the USA (especially California), you must pass Prop 65. This focuses on lead and phthalates.

If your bag fails these tests, customs can seize your container. You will lose the goods and your money.

At Coraggio, we send fabric samples to SGS or Intertek for testing before we start mass production. We test for:

- Lead content: Must be below 90ppm.

- Cadmium: A dangerous metal.

- Azo Dyes: Chemicals that can cause cancer.

You must ask your supplier: "Do you test every batch of recycled fabric for heavy metals?" If they say no, it is a big risk.

How Do You Ensure Traceability Across the Supply Chain?

Your customers want to know the story of the bag. You need to prove where it came from.

Ask for a full supply chain map18. A good supplier knows the yarn spinner, the weaver, and the dyer. Traceability means you can track the plastic bottle all the way to the finished backpack.

Dive Deeper

Traceability is the future of our industry. Big brands in Europe are already demanding this. They want to know the name of the factory that melted the bottles.

When I work with a client like you, I practice open-book management regarding materials. I can show you:

- The Source: Which recycling center collected the bottles.

- The Spinner: The factory that turned plastic chips into thread.

- The Weaver: The factory that made the fabric.

Why is this important? Because of "Greenwashing." Some companies claim to be sustainable but provide no proof. By mapping the supply chain, you build trust with your final consumer.

I keep records of all invoices and shipping documents from my material suppliers. If an auditor comes to my factory, I can show them exactly which roll of fabric was used for your specific order. This is the level of detail you should expect from a professional OEM partner.

Conclusion

To succeed with recycled bags, you must verify the material (RPET vs Nylon), demand GRS Transaction Certificates, test for chemicals, and understand the higher MOQs.

Learn exactly how TCs work so you can detect fake documents and ensure your recycled bags are truly certified and traceable. ↩

Understanding how to confirm true fabric origin helps you avoid greenwashing and choose the right material for your product tier. ↩

Knowing benchmark tear strength values lets you set proper specs so bags don’t fail in your customers’ hands. ↩

See how bottle-to-bag recycling really works so you can explain the sustainability story to buyers and consumers. ↩

Clarifying nylon feedstock types helps you position premium products and justify higher prices to your market. ↩

Get technical data on 600D RPET so you can balance cost, durability, and sustainability for mid-range products. ↩

Learning to read SCs lets you check validity, scope, and product categories before placing large orders. ↩

See how order-level TCs protect you legally and commercially when marketing recycled content claims. ↩

Comparing PU vs PVC helps you choose the right backing for flexibility, structure, and environmental profile. ↩

Knowing target tear strength numbers lets you write solid tech packs and avoid costly claims or returns. ↩

Understanding color fastness tests helps you prevent color bleeding complaints and protect your brand image. ↩

Learn how hydrostatic head ratings work so you can specify real-world water resistance for outdoor bags. ↩

Better grasping upstream fabric handling helps you question suppliers and reduce shade variation issues. ↩

Knowing typical MOQs lets you plan assortment, cashflow, and inventory risk for eco collections. ↩

Understanding TC timing avoids launch delays and aligns logistics, marketing, and compliance schedules. ↩

Learning key REACH limits helps you prevent customs seizures and ensure your eco bags are truly safe. ↩

Knowing Prop 65 rules protects you from warning-label issues, lawsuits, and retailer rejections. ↩

Seeing mapping best practices helps you fight greenwashing, pass audits, and tell a credible sustainability story. ↩