Worried about your bags getting stuck at customs due to compliance issues? Hidden supply chain risks can destroy your profit margins overnight. You need transparency now.

Supply chain transparency1 allows bag buyers to verify ethical sourcing2, ensure material quality3, and comply with strict import regulations4 in Europe and North America. It reduces the risk of customs detention5 and builds consumer trust, allowing brands to charge higher prices for traceable products6.

I have seen many buyers lose money because they did not know where their materials came from. Let me explain how you can avoid this trap and grow your business.

How Do New Import Regulations Affect Bag Sourcing from China?

New laws are confusing and strict. Ignoring them causes fines and delays. We must understand them to survive.

New regulations like the UFLPA7 in the US require proof that materials are not made with forced labor8. Without full documentation from your Chinese manufacturer, your shipment will be detained, leading to total financial loss.

I have been in the bag manufacturing industry for 15 years. In the past, buyers only cared about the price. Now, I see containers getting stopped at ports in Long Beach or Rotterdam because the paperwork is missing. This is a nightmare for buyers like you. If you import bags into the US or Europe, you are now responsible for the entire journey of the product. This includes the cotton farm, the zipper factory, and the assembly line.

Governments want to stop forced labor8 and environmental damage9. They use laws like the Uyghur Forced Labor Prevention Act (UFLPA7) in the US and the new Supply Chain Due Diligence Act in Germany. If you cannot prove where your fabric was made, customs will not release your goods. You lose the product, you lose the shipping cost, and you lose your customer's trust.

To help you understand, I have broken down the impact of these regulations on your business. You must look at these factors when choosing a factory.

| Regulation Area | What Customs Checks | Risk to Buyer | Solution |

|---|---|---|---|

| Raw Materials | Origin of cotton or PVC | Shipment Destruction | Require Certificate of Origin |

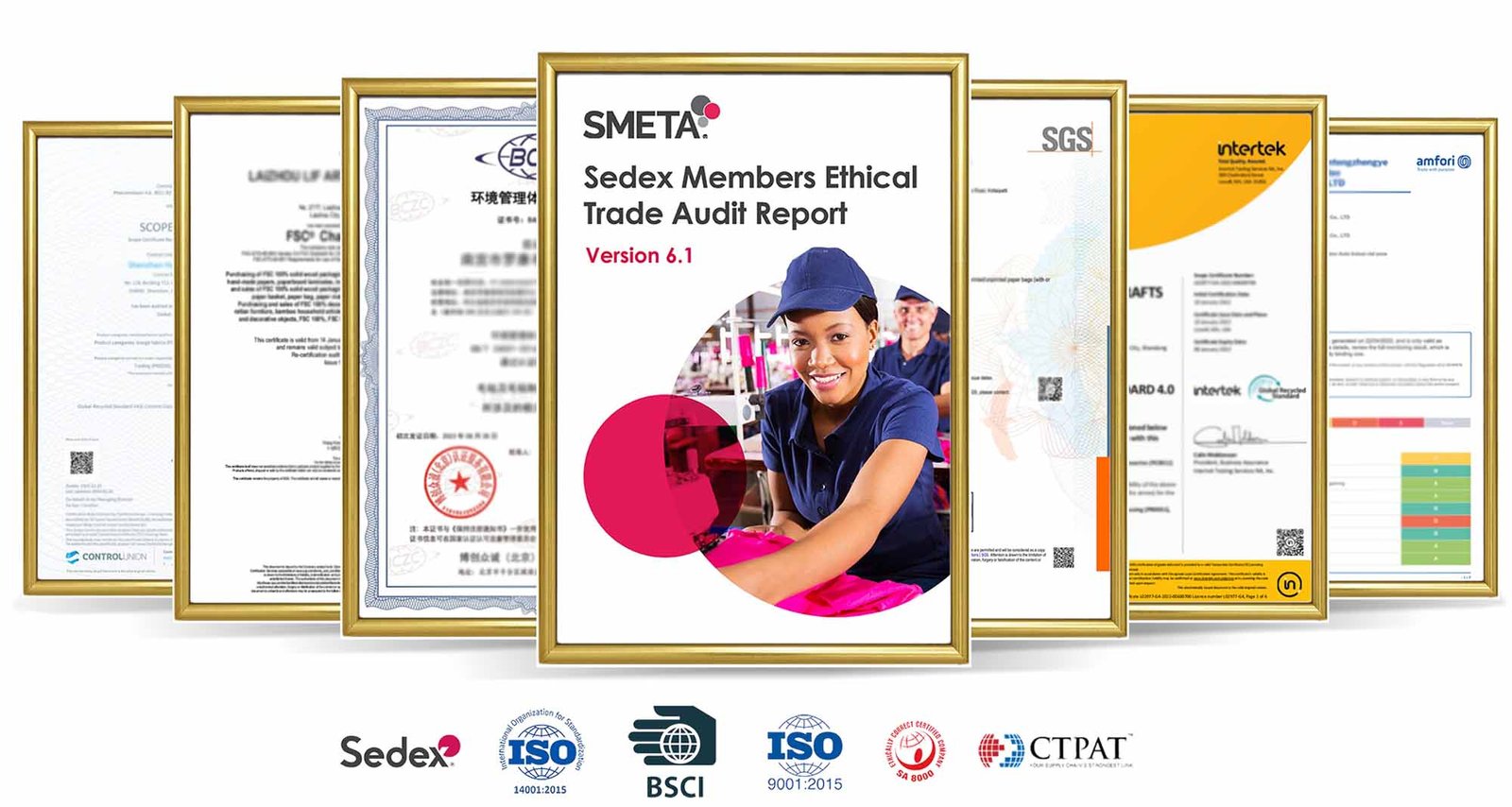

| Labor Rights | Factory worker audits | Brand Reputation Damage | Ask for BSCI10/Sedex Audit |

| Chemicals | REACH/Prop 65 testing | Heavy Fines | Mandate SGS/TUV Testing |

At Coraggio, we keep records for every step. We know that if we do not help you clear customs, we both lose business. You must work with a partner who understands these laws, not just one who offers the cheapest price.

Can Supply Chain Transparency Increase Brand Loyalty and Pricing?

Customers want ethical bags. They leave if you hide things. Transparency wins them back and boosts profit.

Yes, transparency directly allows you to increase prices. Modern consumers willingly pay a premium for brands that prove ethical manufacturing. It builds trust, differentiates your brand from cheap competitors, and creates loyal customers who believe in your story.

I work with many clients from Canada and Europe. The ones who are growing the fastest are not the ones selling the cheapest bags. They are the ones telling a story. When you show your customer exactly how the bag was made, you create value. A generic backpack is just a commodity. A backpack made from recycled plastic bottles with a traceable history is a brand asset.

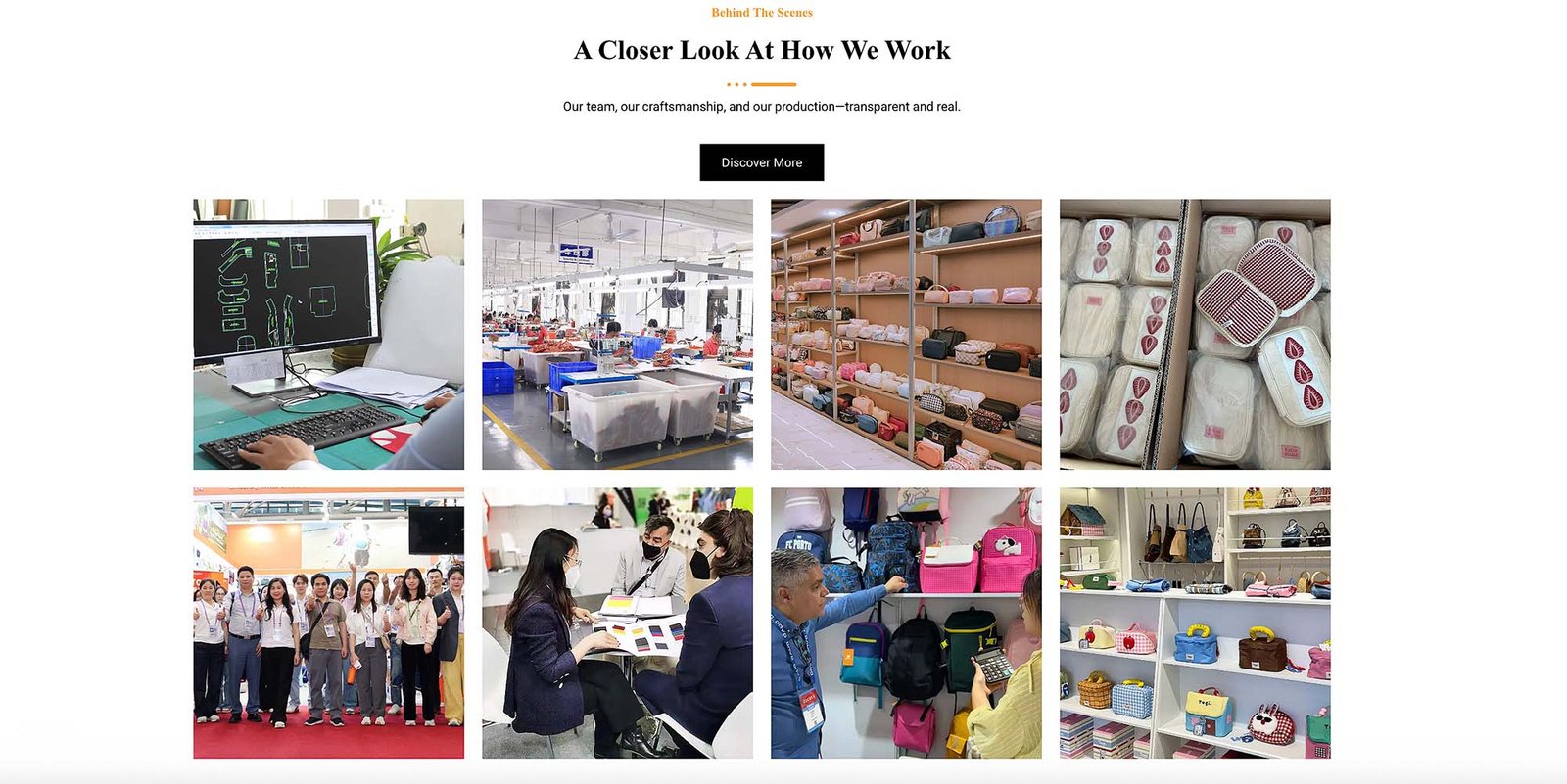

In my 3,000 square meter factory, we often host video calls for our clients. They show their customers our clean production lines and our 120 skilled workers. This proves that the brand cares about people, not just profit. When a consumer sees this, they feel good about buying. They feel safe. This emotional connection creates loyalty.

If you hide your supply chain, customers assume the worst. They think you are using sweatshops or bad materials. But if you are open, you can charge more. Transparency is a marketing tool. It turns a standard product into a premium product.

Here is how transparency changes the perception of your brand:

The Value of Openness

- Trust: Customers believe your quality claims because you show the proof.

- Differentiation: You stand out from competitors who hide their factories.

- Justification: You can explain why your price is higher (better labor, better materials).

You are not just buying a bag from me; you are buying a story that you can sell to your market.

How Does Traceability Ensure Material Quality in Bag Manufacturing?

Inconsistent fabric ruins orders. You cannot sell bad bags. Traceability fixes this by tracking every detail.

Traceability means tracking every roll of fabric and zipper back to its source. It ensures that the eco-friendly materials you paid for are actually used, preventing factory substitutions that lead to quality defects and customer complaints.

One of the biggest pain points for buyers is the "bait and switch." You approve a high-quality sample, but the mass production arrives looking cheap. This happens when a factory swaps materials to save money. They might use a thinner canvas or a zipper that breaks easily. Without traceability11, you have no way to stop this until it is too late.

Traceability solves this problem. When we order materials for your project, we keep the invoices and the testing reports. We label every roll of fabric in our warehouse. If you order a cooler bag with specific insulation, we can prove that we bought the exact material you specified. This is vital for consistency.

I have a design team of 10 people. We know that good design fails if the material is bad. If you are selling "Eco-friendly" bags, you need to be 100% sure the material is recycled. If you sell a fake eco-bag, you could get sued. Traceability protects you from legal trouble and quality issues.

Below is how we ensure quality through traceability11 in our production lines:

| Production Stage | Traceability Action | Benefit to Buyer |

|---|---|---|

| Purchasing | Verify supplier invoices | Ensures correct material grade |

| Warehousing | Label and log incoming stock | Prevents mixing materials |

| Cutting | Record batch numbers | Tracks usage efficiency |

| QC Check | Compare against master sample | Guarantees final quality |

By controlling the input, we control the output. This is how we keep our quality high and your customers happy.

What Should Buyers Ask Manufacturers to Verify Supply Chain Transparency?

Suppliers lie sometimes. You might get scammed. Ask the right questions to be safe and secure.

You should ask for Tier 2 supplier certificates, raw material purchase invoices, and third-party audit reports like BSCI10 or ISO. Also, ask if they allow surprise on-site inspections to verify the production lines and worker conditions match their claims.

I know it is hard to trust a supplier you meet online. You are in Canada or Europe, and the factory is in China or Vietnam. How do you know they are telling the truth? You must ask specific questions that fake factories cannot answer. A trading company pretending to be a factory will struggle to show you the details of the production floor.

First, ask for the "Bill of Materials12" (BOM) with supplier names. If they refuse to tell you where they buy the fabric, they are hiding something. Second, ask for their audit reports. At Coraggio, we are proud of our certifications. We show them to anyone who asks. If a supplier makes excuses about why they cannot show you a certificate, run away.

You should also ask for a video tour. Not a pre-recorded video, but a live video call13. Ask them to walk to the warehouse. Ask them to show you the cutting machine. This is very hard to fake.

Here is a checklist of documents you should request before placing a big order:

The Transparency Checklist

- Business License: Check if the scope says "Manufacturing" or just "Trading."

- ISO 9001 Certificate: This proves they have a quality management system.

- Material Test Reports: REACH (for Europe) or CA65 (for US).

- Social Audit Reports: BSCI10, Sedex, or SA8000 to prove ethical labor.

- Sub-supplier List: Names of the factories providing zippers, buckles, and fabrics.

Do not be afraid to be annoying. A good supplier will respect your thoroughness. We want long-term partners, not just one quick deal. When you ask these questions, you filter out the bad options and find the partners who can actually help you succeed.

Conclusion

Supply chain transparency1 protects you from legal risks, ensures consistent product quality, and builds a stronger brand. Partner with transparent manufacturers to secure your business future.

Understanding supply chain transparency can help you ensure ethical sourcing and compliance, crucial for your business. ↩

Exploring ethical sourcing can enhance your brand's reputation and attract conscious consumers. ↩

Ensuring material quality is crucial for customer satisfaction and brand reputation. ↩

Staying updated on import regulations is vital to avoid fines and ensure smooth customs clearance. ↩

Understanding customs detention can help you mitigate risks and protect your profit margins. ↩

Traceable products build consumer trust and can justify higher pricing for your brand. ↩

Learning about UFLPA is essential for compliance and avoiding legal issues in your supply chain. ↩

Preventing forced labor is not only ethical but also essential for compliance and brand integrity. ↩

Understanding environmental impacts can help you adopt sustainable practices and appeal to eco-conscious consumers. ↩

BSCI audits ensure ethical labor practices, enhancing your brand's credibility and consumer trust. ↩

Traceability is key to maintaining quality and preventing costly production errors. ↩

A BOM provides transparency in sourcing, helping you ensure quality and compliance. ↩

A live video call can provide real-time insights into a supplier's operations, ensuring transparency. ↩