You see the high-quality cosmetic bags from big brands and wonder where they come from. You want that same quality for your business, but finding the right source is frustrating.

Estée Lauder cosmetic bags are primarily manufactured in China due to the mature supply chain1 and advanced production technology2 found there. However, a portion of their orders is also produced in Southeast Asian countries like Vietnam to take advantage of lower labor costs and specific tariff benefits3.

Many buyers think big brands have secret factories. They do not. They use the same global supply chain4 that is available to you. I have been in this industry for 15 years. I see where the materials come from and where the finished goods go. If you understand their sourcing strategy, you can improve your own procurement process. Read on to learn the details.

Why is China the primary manufacturing hub for these bags?

You worry about supply chain stability and finding the right materials. China solves these problems because the entire industry is located in one place.

China remains the top choice for Estée Lauder cosmetic bags because of its complete industrial chain. From zippers and fabrics to skilled labor and printing technology, everything is locally available, which ensures speed and quality control.

I run a factory with 120 workers and 8 production lines. I see every day why China is still the king of bag manufacturing. It is not just about the sewing. It is about the ecosystem. When Estée Lauder needs a specific gold zipper or a custom vegan leather, I can find it within 20 kilometers of my factory. This is the "cluster effect5."

In my 3,000 square meter facility, we handle OEM and ODM orders6. We know that big brands need complex designs. China has the machinery to do complex embroidery, digital printing, and heat transfer logos all in the same city. If you move production to a place with a weak supply chain, you wait weeks for materials to arrive. In China, materials arrive in hours.

Also, the workers here are very fast. My team has been making bags for over a decade. They know how to handle difficult fabrics without wrinkling them. This skill takes years to build. For a brand like Estée Lauder, a messy stitch is not acceptable. They choose China because the risk of errors is low.

Here is a breakdown of why the supply chain matters:

| Feature | China Manufacturing | Other Developing Countries |

|---|---|---|

| Raw Material Access | Immediate (Local) | Slow (Import required) |

| Worker Skill Level | High (15+ years experience) | Variable (Training needed) |

| Turnaround Time | Fast (Integration) | Slower (Logistics delays) |

| Customization | High complexity possible | Best for simple items |

Do Southeast Asian countries produce Estée Lauder bags?

You want the lowest price possible to increase your profit margin. You might think Southeast Asia is cheaper, but is it reliable?

Yes, Southeast Asian countries like Vietnam and Cambodia produce some Estée Lauder bags. Big brands move large, simple orders there to save on labor costs and avoid certain import tariffs to North America.

Price is always a pain point for buyers like you. I understand this. You need to buy low and sell high. Estée Lauder also wants to save money. That is why they use a "China Plus One" strategy. They keep complex orders in China. They move simple, huge volume orders to Vietnam or Cambodia.

However, there is a catch. Most of the raw materials used in Vietnam still come from China. The fabric, the metal hardware, and the packaging are shipped from China to Vietnam for assembly. This adds time to the delivery date. If you have a tight deadline, this is risky.

Also, the Minimum Order Quantity (MOQ)7 in Southeast Asia is usually very high. Factories there operate on volume. They are not flexible. At Coraggio, I can help with smaller, personalized customization because my production lines are flexible. In Southeast Asia, if you do not order 50,000 pieces, they might not talk to you.

You must look at the total cost. Labor is cheaper there. But logistics and material shipping cost more. For a luxury gift bag, the quality is the most important thing. If the stitching is bad, your brand looks bad. China still holds the advantage for consistent quality in the mid-to-high-end market.

How do big brands control quality in these factories?

You have received bad products before, and it hurt your business. You need to know how to prevent quality issues before they ship.

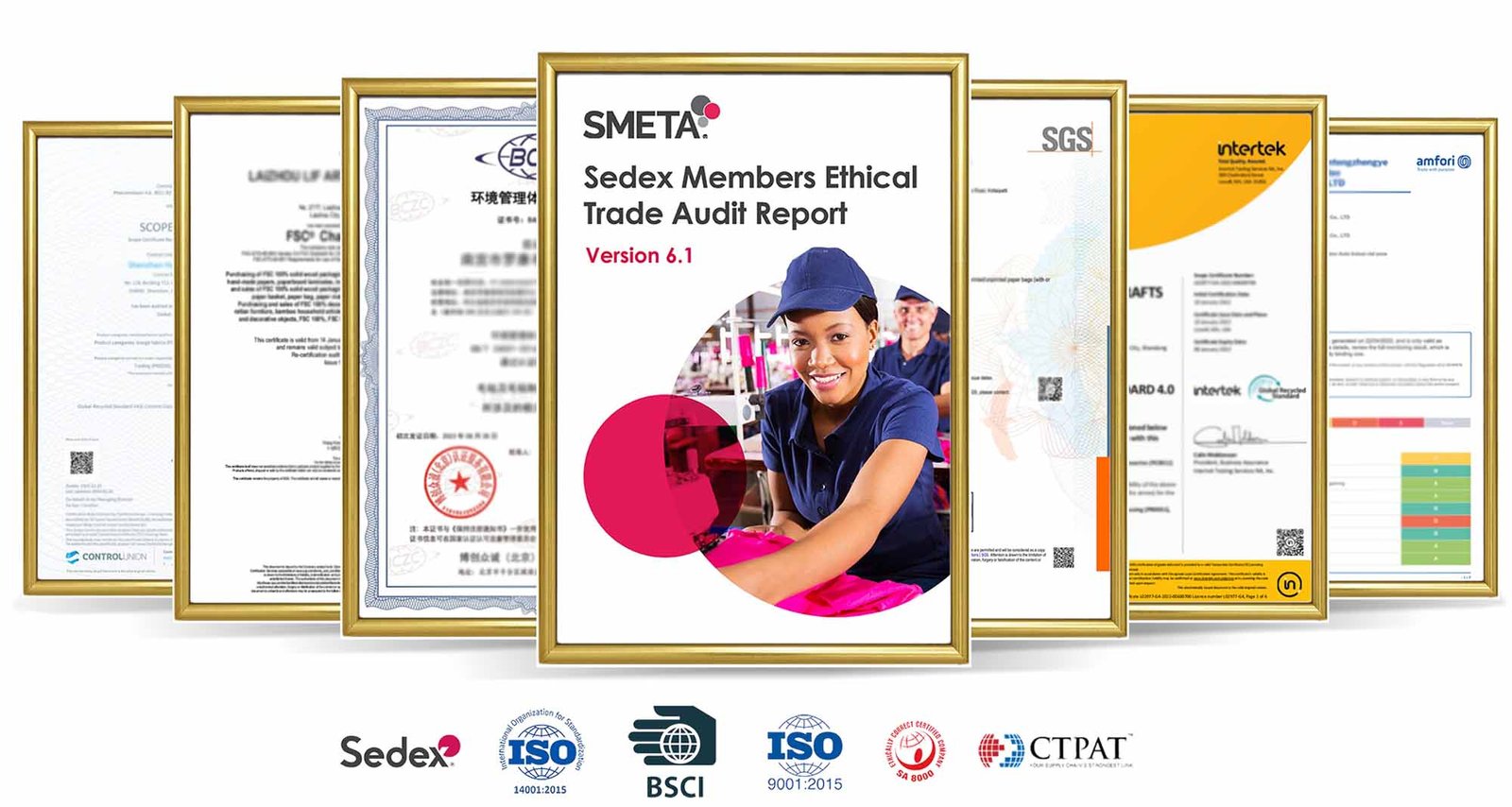

Big brands like Estée Lauder strictly control quality through third-party inspections8 and factory certifications9. They require manufacturers to pass audits like ISO and BSCI to ensure consistent product standards and ethical labor practices.

Quality control is my life. In my factory, we do not let a bag leave the line if it is not perfect. Estée Lauder works the same way. They do not just trust the factory owner. They send inspectors.

When you buy from overseas, you cannot be there every day. You need a system. At Coraggio, we have a specific QC team. We inspect the raw material when it arrives. We inspect the semi-finished panels. We inspect the final bag. This is called AQL (Acceptable Quality Limit).

Big brands also care about social responsibility. They ask for BSCI (Business Social Compliance Initiative) certification. This proves we treat our 120 workers well. Happy workers make better bags. If you source from a factory that treats workers badly, you risk your reputation.

Here is the typical QC process for a high-end cosmetic bag:

- Pre-production Meeting: We discuss the sample with the design team (I have 10 people in mine). We identify potential risks.

- Material Check: We check the thickness and color of the PU or leather.

- Inline Inspection: My QC manager walks the line every hour. He checks stitch tension and zipper smoothness.

- Final Inspection: Every single bag is cleaned and checked before packing.

- Lab Testing: We test for lead, durability, and color fastness.

You should ask your supplier for their QC reports. If they cannot show you, run away.

What materials are used in Estée Lauder cosmetic bags?

You want your products to look expensive but cost little. You also know that customers today want eco-friendly options10.

Estée Lauder cosmetic bags use a variety of materials including PU leather11, polyester, and increasingly, recycled materials like RPET12. These materials offer a balance of luxury appearance, durability, and environmental responsibility.

Material selection is where the profit is made. You want a bag that feels like $50 but costs $2 to make. We use PU (Polyurethane) often. It looks like leather. It feels soft. But it is cheap and easy to clean. This is perfect for cosmetic bags because makeup spills happen.

Recently, I see a big change. Buyers want "Green" products. Estée Lauder is doing this too. They use RPET. This is fabric made from recycled plastic bottles. My factory has certifications for these materials. If you sell to Europe or North America, this is a huge selling point.

We also use Canvas and PVC. PVC is clear. It is good for travel bags because you can see what is inside. It is very cheap. But you must use high-quality PVC or it will crack in cold weather.

Here is a comparison of popular materials I use for my clients:

| Material | Feel | Cost | Best Use |

|---|---|---|---|

| PU Leather | Soft, Luxury | Medium | High-end Gift with Purchase |

| RPET (Recycled) | Textured, Durable | Medium-High | Eco-conscious brands |

| PVC | Smooth, Plastic | Low | Travel kits, Airport security |

| Nylon | Slick, Sporty | Medium | Men's toiletry bags |

My design team can help you choose. We can send you swatches. You need to feel the material. A picture is not enough.

How can you find a manufacturer like Estée Lauder's?

You are tired of middlemen and trading companies taking your profit. You want to go direct to the factory to get the best price and service.

You can find manufacturers with similar capabilities by using B2B platforms13, attending trade shows14 like the Canton Fair15, and searching for suppliers with specific certifications. Look for factories that offer OEM/ODM services16 and have a proven track record.

Finding a good supplier is like dating. You have to look in the right places. Mark, you are experienced. You know that Google is a good start. But you get millions of results. How do you filter them?

Look for details. Does the website show the factory floor? Do they have a real address? I put my address and factory photos on my website because I have nothing to hide. I want you to see my 8 production lines.

Trade shows are great. You can talk to the owner face to face. You can see the quality of the samples. But travel is expensive and takes time.

B2B platforms13 are easy but dangerous. There are many trading companies pretending to be factories. They add a margin to the price. They confuse the communication. You ask for X, they tell the factory Y.

Here is my advice for you:

- Ask for a video call. I do this with my clients. I walk them through the workshop.

- Ask about their design team. A real factory helps you develop the product. I have 10 designers who can turn your sketch into a bag in 3 days.

- Check their main markets. If they export to Europe and North America, they understand your quality standards.

You do not need to be Estée Lauder to get their quality. You just need a partner who understands your business model. You need a factory that delivers on time and honors the price.

Conclusion

Estée Lauder bags are made in China and Southeast Asia to balance quality and cost. To get similar results, find a transparent Chinese manufacturer with strong QC and eco-friendly options10.

Understanding a mature supply chain can help you identify reliable manufacturing partners and improve your business's procurement process. ↩

Exploring advanced production technology can give insights into how to enhance production efficiency and product quality. ↩

Learning about tariff benefits can help you make informed decisions about where to manufacture your products to save costs. ↩

Understanding the global supply chain can help you leverage international resources for better product sourcing and cost management. ↩

The cluster effect can significantly reduce production time and costs by having all necessary resources in close proximity. ↩

Knowing the difference between OEM and ODM can help you choose the right manufacturing approach for your business needs. ↩

Understanding MOQ can help you negotiate better terms with manufacturers and manage inventory effectively. ↩

Third-party inspections can provide unbiased quality checks, ensuring that your products meet the required standards before shipping. ↩

Factory certifications ensure compliance with industry standards, enhancing product quality and consumer trust. ↩

Eco-friendly options can attract environmentally conscious consumers and enhance your brand's sustainability credentials. ↩

PU leather offers a luxurious look at a lower cost, making it an attractive material for high-end products. ↩

Using recycled materials like RPET can enhance your brand's eco-friendly image and appeal to environmentally conscious consumers. ↩

B2B platforms can simplify the process of finding and connecting with manufacturers, saving time and resources. ↩

Trade shows provide opportunities to meet suppliers face-to-face, evaluate product quality, and establish valuable business relationships. ↩

Attending the Canton Fair can connect you with a wide range of suppliers and manufacturers, offering opportunities for business growth. ↩

OEM/ODM services allow for customized product development, enabling businesses to create unique offerings. ↩