Hey there! Have you ever wondered why bags made in China are so much cheaper than those made elsewhere? It’s a question that’s crossed the minds of many bag buyers and business owners like you and me. Let’s dive into the fascinating reasons behind this phenomenon. By the end, I’ll also share a fantastic bag recommendation you will want to take advantage of!

Snippet Answer Paragraph:

China’s ability to manufacture bags cheaply is largely due to its low labor costs, a strong business ecosystem, lax commercial regulations, tax incentives, and competitive currency practices. These factors combine to create an environment where production is efficient and cost-effective, allowing companies to produce high-quality bags at a fraction of the cost compared to other countries.

Now, you might be thinking, “Is it just the cheap labor?” Well, there’s more to the story. Beyond the low wages, China has established an impressive manufacturing infrastructure over the years. This includes everything from advanced machinery to skilled labor explicitly trained for mass production. Such an infrastructure not only boosts efficiency but also ensures that the quality of bags remains high while keeping the costs low. This combination of low labor costs and top-notch manufacturing capabilities gives China its competitive edge.

Let’s take a closer look at the various factors that make China the go-to destination for affordable bag manufacturing:

How Do China Bag Manufacturers Produce So Cheaply?

When you hear about the affordability of bags manufactured in China, it’s natural to wonder about the underlying reasons. Several key factors contribute to China’s ability to produce bags at such low costs:

1. Low Labor Costs:

As mentioned earlier, China’s labor costs are significantly lower than many other countries. This is mainly due to the vast labor pool available, allowing manufacturers to hire skilled workers at lower wages. The lower cost of living in many parts of China also contributes to this dynamic, making labor an economic resource.

2. Strong Business Ecosystem:

China’s well-established business ecosystem is another crucial factor. This ecosystem includes a comprehensive network of suppliers, manufacturers, and logistics providers collaborating efficiently. This integrated system minimizes production delays and reduces costs, ensuring that manufacturing processes are swift and economical.

3. Economies of Scale:

Chinese manufacturers benefit from economies of scale due to the high production volume. Manufacturers can spread the fixed costs over more units by producing large quantities of bags, reducing the cost per unit. This scalability is a significant advantage that smaller manufacturers in other countries might lack.

4. Advanced Manufacturing Technology:

Over the years, China has invested heavily in advanced manufacturing technology. State-of-the-art machinery and equipment enable high efficiency and precision in production. These technological advancements mean manufacturers can produce high-quality bags quickly and cheaply.

5. Lax Commercial Regulations:

The Chinese government has implemented relatively lax commercial regulations, making it easier and cheaper for businesses to set up and operate factories. This includes simplified procedures for obtaining licenses and permits, fewer restrictions on business operations, and supportive industrial policies. As a result, companies face fewer regulatory hurdles and can focus more on production efficiency.

6. Government Incentives:

The Chinese government offers various incentives such as tax breaks, subsidies, and reduced tariffs to attract and retain manufacturing businesses. These financial incentives lower the overall cost of production and encourage manufacturers to maintain their operations within China.

7. Efficient Supply Chain:

China boasts an incredibly efficient supply chain, with raw materials and components readily available at competitive prices. Proximity to these resources reduces transportation costs and delays, lowering manufacturing costs. The well-developed infrastructure, including ports, railways, and highways, also facilitates smooth logistics and distribution.

8. Competitive Currency Practices:

The value of the Chinese yuan is often kept lower than that of other currencies through competitive currency practices. This makes Chinese exports cheaper globally, helping Chinese manufacturers offer lower prices for their products internationally.

By leveraging these factors, Chinese bag manufacturers can produce high-quality bags at a fraction of the cost compared to other countries. This combination of low labor costs, advanced technology, efficient supply chains, and supportive government policies creates a perfect environment for affordable bag production.

How Much Does It Cost to Get Something Manufactured in China?

When considering the cost of manufacturing goods in China, it’s essential to understand the various elements contributing to the overall expense. While the exact cost can vary depending on the product and specific requirements, several vital factors typically influence the pricing.

1. Direct Costs:

At the core of manufacturing costs are direct expenses such as labor and materials. Labor costs in China are significantly lower than in many Western countries. For instance, the average manufacturing wage in China is approximately $3.60 per hour compared to $22.50 per hour in the United States. This stark difference means companies can save a substantial amount on wages alone. Material costs are also generally lower due to the proximity of raw materials and a well-established network of suppliers. For every dollar spent on manufacturing in the U.S., it costs roughly 96 cents to produce the same item in China. This slight percentage difference can translate into significant savings when scaled to large production volumes.

2. Overhead and Indirect Costs:

In addition to direct costs, businesses must also consider overhead and

indirect expenses. These include factory maintenance, utilities, and

administrative costs. China has an extensive manufacturing infrastructure

that supports high production volumes. This leads to economies of scale that further reduce these costs per unit. Furthermore, many Chinese factories benefit from government subsidies and tax incentives to attract foreign investment and support local industries. These financial benefits help lower the overall cost of production, making Chinese manufacturing an attractive option for many companies.

3. Logistics and Supply Chain Efficiency:

The efficiency of China’s supply chain and logistics infrastructure also plays a crucial role in reducing manufacturing costs. With well-developed transportation networks, including ports, railways, and highways, China ensures smooth and cost-effective movement of goods both domestically and internationally. This efficiency minimizes delays and lowers shipping costs, making getting products from the factory to the global market cheaper. Furthermore, many Chinese manufacturers offer comprehensive services, including sourcing, production, quality control, and shipping, streamlining the entire manufacturing process and reducing additional costs associated with managing multiple suppliers.

In summary, manufacturing in China generally costs less due to lower labor and material expenses, economies of scale, government incentives, and a highly efficient supply chain. While the exact cost will vary based on the specific product and production requirements, these factors collectively enable significant cost savings, making China a preferred destination for global manufacturing.

What Are the Disadvantages of Manufacturing in China?

While manufacturing in China offers numerous cost advantages, it’s essential to consider the potential drawbacks that can impact businesses. Understanding these disadvantages can help companies make more informed decisions and develop strategies to mitigate risks.

1. Quality Control Issues:

Maintaining consistent product quality is one of the most significant concerns when manufacturing in China. Although many Chinese factories produce high-quality goods, there is still a variability risk, especially when working with new or less-established manufacturers. Companies often need help with issues such as defective products, substandard materials, and deviations from design specifications. To address these challenges, businesses may need to invest in stringent quality control measures, including regular inspections, audits, and on-site visits, which can add to the overall cost and complexity of the manufacturing process.

2. Intellectual Property Risks:

Intellectual property (IP) protection is another critical issue in China’s manufacturing industry. Despite improvements in IP laws and enforcement, counterfeiting and unauthorized production remain prevalent problems. Companies risk having their designs, patents, and trademarks copied and sold without permission, leading to significant financial losses and damage to brand reputation. To mitigate these risks, businesses should register their IP rights in China, work with reputable manufacturers, and consider implementing strict confidentiality agreements and security measures.

3. Language and Cultural Barriers:

Communication can be challenging due to language differences and cultural nuances. Misunderstandings and misinterpretations can occur, leading to errors in production, delays, and increased costs. Navigating these barriers requires a good understanding of Chinese business culture. It often necessitates hiring bilingual staff or working with experienced intermediaries who can bridge the communication gap. Building solid relationships with local partners and maintaining clear, consistent communication is crucial for successful manufacturing operations.

4. Shipping and Logistics Challenges:

While China has a well-developed transportation infrastructure, international shipping can still present challenges. Long shipping times, customs clearance issues, and fluctuating shipping costs can affect the reliability and predictability of supply chains. Additionally, global events such as trade wars, pandemics, and geopolitical tensions can disrupt logistics and increase costs. Companies must be prepared for potential delays and additional expenses related to international shipping and develop contingency plans to ensure a steady supply of products.

5. High Minimum Order Quantities (MOQs):

Many Chinese manufacturers require high minimum order quantities to justify production runs. For small businesses or companies testing new products, these MOQs can be prohibitive, leading to higher upfront costs and increased financial risk. While negotiating lower MOQs is sometimes possible, it often requires a strong relationship with the manufacturer and a commitment to long-term collaboration.

6. Regulatory and Compliance Issues:

Navigating the regulatory environment in China can be complex and challenging. Companies must ensure compliance with local laws and regulations, which can vary by region and industry. This includes obtaining the necessary licenses and permits, adhering to labor and environmental standards, and staying updated on policy changes. Non-compliance can result in fines, legal issues, and disruptions to business operations.

In summary, while manufacturing in China offers many advantages, businesses must be aware of the potential disadvantages, including quality control issues, intellectual property risks, language and cultural barriers, shipping and logistics challenges, high minimum order quantities, and regulatory compliance issues. By understanding these drawbacks and implementing strategies to address them, companies can better navigate the complexities of manufacturing in China and leverage its benefits effectively.

How Do US Companies Get Bags Produced in China?

US companies looking to get bags produced in China often follow a structured process to ensure successful and cost-effective manufacturing. Here’s a detailed look at the steps involved, highlighting key considerations and best practices.

1. Identifying the Right Manufacturer:

The first step is finding a reliable manufacturer. Companies typically start by researching and compiling a list of potential manufacturers. Platforms like Alibaba, Global Sources, and Made-in-China.com are popular for connecting with Chinese suppliers. Business owners often attend trade shows like the Canton Fair to meet manufacturers and evaluate their capabilities. Search engines like Google.com can also help buyers find manufacturers by searching for terms like “bag manufacturers in China” or “custom bag factories in China,” which can provide a wide array of options to explore. It is crucial to assess potential partners based on their production capacity, quality standards, certifications, and past client reviews.

2. Vetting and Auditing Factories:

Once a list of potential manufacturers is created, vetting and auditing these factories is the next step. This involves conducting thorough background checks to verify their legitimacy and capabilities. Many companies hire third-party inspection agencies to perform factory audits. These audits assess the factory’s production processes, quality control measures, labor practices, and compliance with international standards. Visiting the factory in person can also provide valuable insights into their operations and build stronger business relationships.

3. Establishing Clear Documentation:

Clear, comprehensive documentation is essential for successful manufacturing. Companies must provide detailed bag specifications, including materials, dimensions, colors, designs, and other specific requirements. Production-ready documentation, such as technical drawings, prototypes, and sample products, helps ensure the manufacturer fully understands the product requirements. Clear documentation minimizes the risk of errors and misunderstandings during production.

4. Negotiating Terms and Prices:

Negotiating favorable terms and prices is a critical step. Companies must discuss pricing, payment terms, production timelines, minimum order quantities, and additional services like packaging and shipping. Understanding the cost breakdown and negotiating to get the best value without compromising quality is essential. Establishing clear terms in a written agreement or contract protects both parties and sets expectations for the manufacturing process.

5. Quality Control and Production Monitoring:

Ensuring consistent product quality is vital. Companies often implement strict quality control measures, including setting up a quality assurance team, conducting regular inspections, and using third-party inspection services. These measures help identify and rectify any issues early in the production process. Some businesses also opt to station a representative at the factory to monitor production and ensure adherence to quality standards.

6. Shipping and Logistics:

After production, the next challenge is shipping the bags to the US. Companies need to manage logistics, including arranging freight, handling customs clearance, and dealing with potential shipping delays. Working with experienced freight forwarders and customs brokers can simplify this process. It’s important to factor in shipping costs and timelines when planning the production schedule to ensure timely delivery.

7. Building Long-Term Relationships:

Successful manufacturing often hinges on building and maintaining strong relationships with Chinese partners. Companies should invest time in understanding cultural nuances and fostering good communication. Regular interactions, feedback, and visits can strengthen the partnership and lead to better collaboration. Building trust and reliability can result in more favorable terms and smoother production processes.

Key Considerations and Best Practices:

- Legal Protections: Protecting intellectual property is crucial when manufacturing abroad. Companies should register their trademarks and patents in China and consider legal agreements like Non-Disclosure Agreements (NDAs) and Non-Compete Agreements (NCAs) to safeguard their designs and innovations.

- Cultural Sensitivity: Understanding and respecting cultural differences can enhance business relationships. Knowing local business etiquette, holidays, and communication styles can facilitate smoother interactions and negotiations.

- Risk Management: Diversifying suppliers and having contingency plans can help mitigate risks associated with relying on a single manufacturer. It’s wise to have backup suppliers to avoid disruptions due to unforeseen issues like factory closures or supply chain disruptions.

In summary, getting bags produced in China involves a multi-step process that includes identifying the correct manufacturer, vetting and auditing factories, establishing clear documentation, negotiating terms, implementing quality control, managing logistics, and building long-term relationships. By following these steps and best practices, US companies can successfully navigate the complexities of manufacturing in China and leverage its advantages for cost-effective and high-quality production.

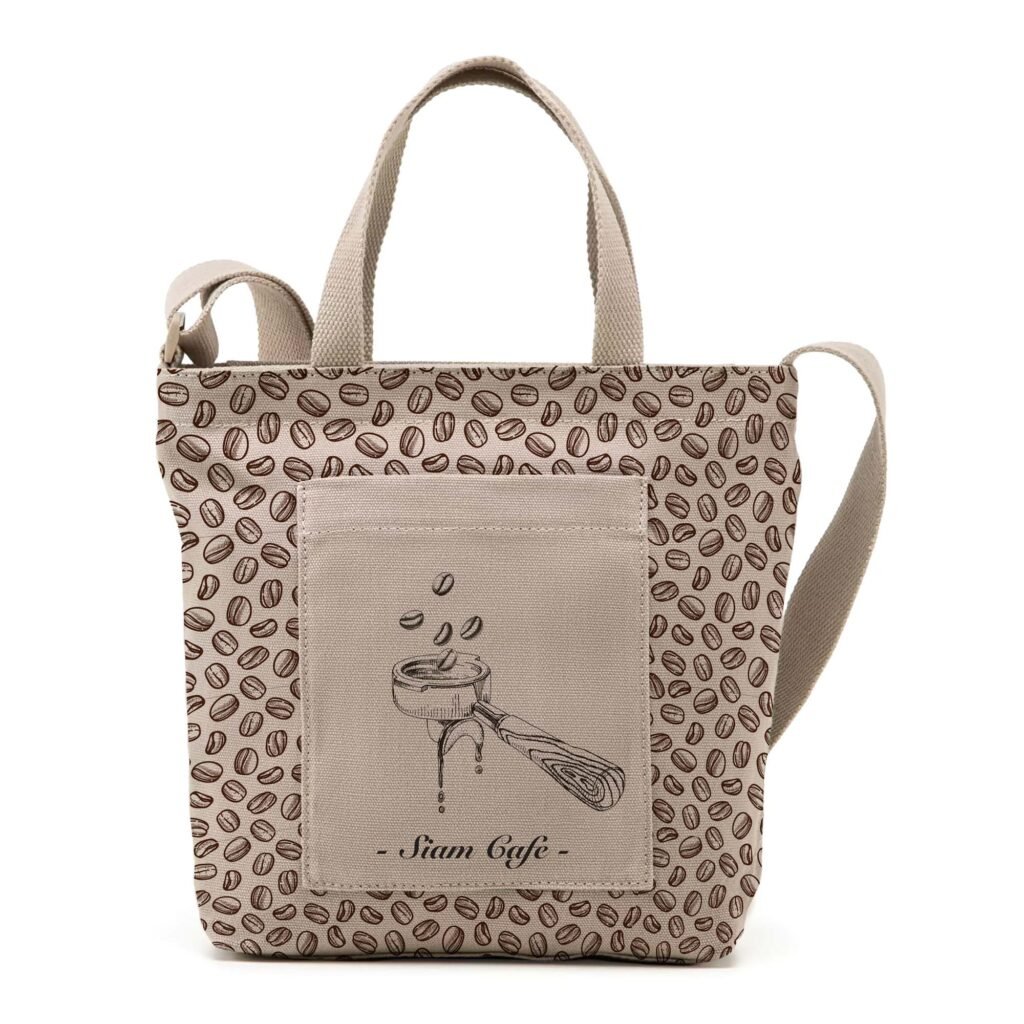

My Bag Recommendation: Coraggio Bags

If you’re looking for stylish, durable, and affordable bags, let me introduce you to Coraggio Bags. This brand has genuinely impressed me with its commitment to quality and customer satisfaction. Coraggio Bags are known for their exceptional craftsmanship, using high-quality materials that ensure durability and longevity. Each bag is meticulously designed, with attention to detail evident in every stitch and piece of hardware. The versatile range of styles—from sleek, professional handbags to casual and trendy backpacks—caters to various tastes and needs, ensuring something for everyone

Despite the premium quality and stylish designs, Coraggio Bags remain surprisingly affordable. This perfect balance between quality and cost provides excellent value for money, making it an attractive option for individual buyers and businesses. Furthermore, Coraggio is committed to sustainability, using eco-friendly materials and ethical manufacturing processes. Choosing Coraggio Bags means getting a great product and supporting a company that values environmental responsibility. Whether you need a reliable bag for everyday use or want to partner with a dependable supplier, Coraggio Bags is an excellent choice. Check out their collection—you won’t be disappointed!