Starting a bag brand is a big challenge, and the biggest fear is often money. You worry about spending your entire budget on bags that might sit in a warehouse forever.

Low MOQ (Minimum Order Quantity)1 is vital because it allows startups to test the market with minimal capital. It prevents inventory overstock2, keeps cash flow3 open for marketing, and offers flexibility to pivot designs4 based on real customer feedback.

I have worked in the bag manufacturing industry for 15 years. I have seen many new brands fail, not because their designs were bad, but because they bought too much stock too soon. They ran out of cash before they could find their customers. Today, I want to explain why starting small is actually the smartest way to grow big.

Why Low MOQ is Vital for Bag Startups?

You have a limited budget to launch your business. If you spend all your money on production, you have nothing left to sell the product.

Low MOQ is vital because it reduces the financial barrier to entry5. It lets you validate your product idea6 without risking your entire budget on a single massive production run.

When you start a business, cash is your oxygen. If you lock all your cash into 3,000 bags, you cannot breathe. At Coraggio, I often tell new clients that production is only one part of the game. You need money for ads, for your website, and for shipping.

Low MOQ allows you to spread your risk7. Instead of betting $50,000 on one bag style, you can bet $5,000. If the bag sells, great. We can make more quickly. If it does not sell, you still have money left to try a different design. This is crucial for survival.

Here is a simple breakdown of how Low MOQ helps your budget:

The Financial Impact of MOQ

| Feature | High MOQ (Traditional) | Low MOQ (Startup Friendly) |

|---|---|---|

| Initial Cost | Very High ($20k+) | Low ($2k - $5k) |

| Cash for Ads | Zero or Low | High |

| Storage Cost | Expensive | Cheap |

| Risk Level | High | Low |

By keeping the order quantity low, you keep your business agile. You can react to the market8. This is the only way to survive the first year of business.

What Does Low MOQ Mean in Bag Manufacturing?

You see the term MOQ on every supplier website. But the number can change depending on the material, the style, and the factory.

In bag manufacturing, Low MOQ usually refers to orders between 50 to 300 pieces per style. It depends on materials and customization levels, but it is significantly lower than the standard 1,000-piece requirement.

To understand MOQ, you have to understand how we make bags. Setting up a production line takes time. We have to cut the fabric, set up the machines, and train the workers for your specific style. This costs the same amount of money whether we make 10 bags or 10,000 bags.

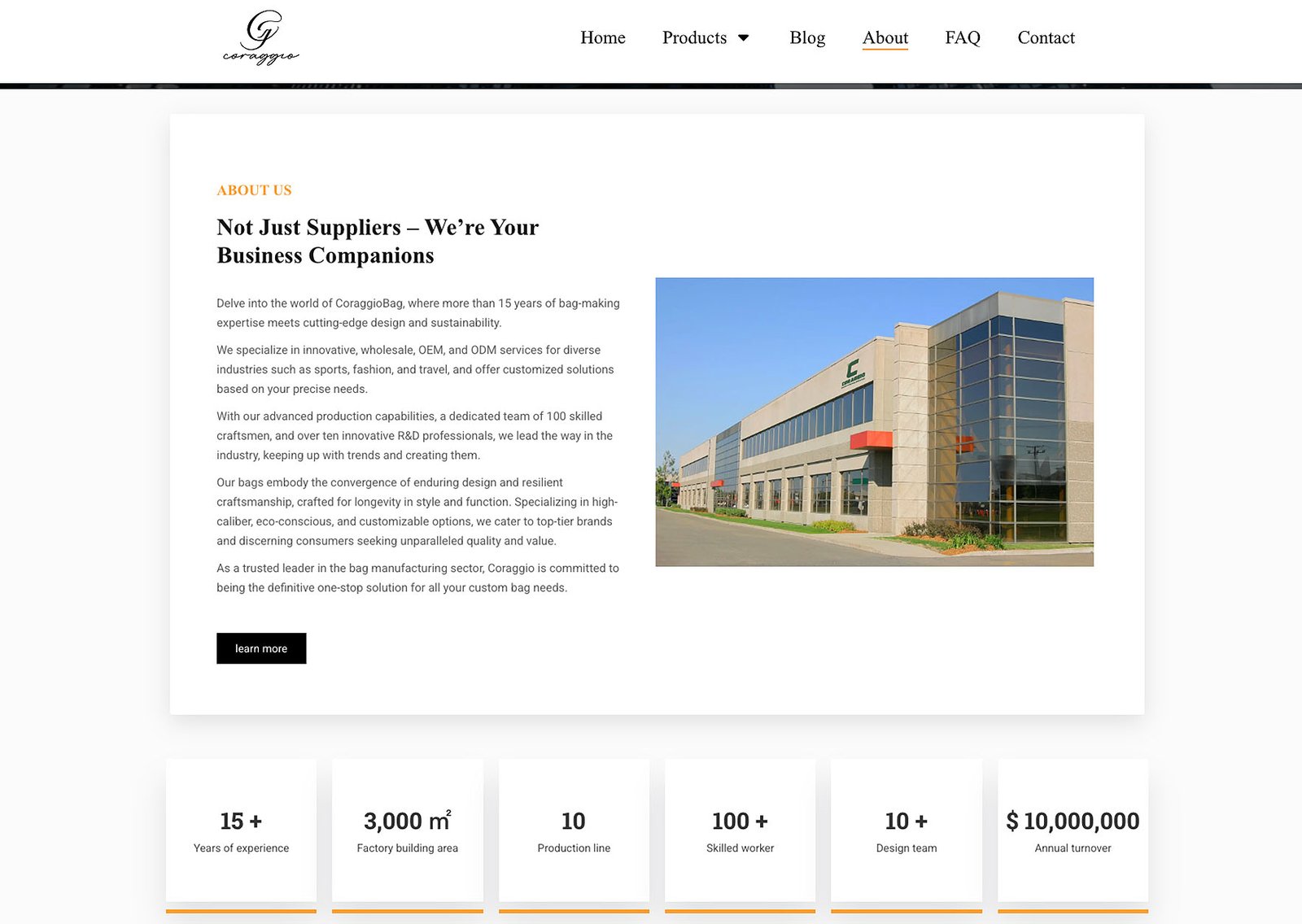

At Coraggio, we have 8 production lines. Some are for huge orders from big supermarkets. But we also have teams for smaller orders.

Here are the factors that decide your MOQ:

1. Material Availability

If you want a custom color fabric that needs to be dyed, the fabric factory will demand a high MOQ. This forces us to demand a high MOQ from you. If you use stock fabric (fabric we already have), the MOQ can be much lower.

2. Customization Complexity

Simple tote bags are easy to make in small batches. Complex backpacks with many zippers and pockets take longer to set up.

3. Logo and Printing

Printing a logo requires a mold or a screen. The cost of the mold is fixed. If you order few bags, the cost per bag goes up, but we can still do it.

Understanding this helps you negotiate. If you are flexible with materials, we can be flexible with MOQ.

How Does Low MOQ Minimize Inventory Risk?

Unsold inventory is a nightmare for any business owner. It takes up space in your garage or warehouse and kills your profit margin.

Low MOQ minimizes risk by matching your production closely with actual demand. You only make what you can sell quickly, ensuring you are not left with "dead stock" that you cannot move.

I have a customer from Canada, let's call him Mark. He once bought 5,000 units of a red backpack from a different supplier because the price was cheap. But the red color was not popular that year. He sold 500. The other 4,500 packs sat in his warehouse for two years. He had to pay for storage every month. Eventually, he threw them away. That is a huge loss.

This is the "Inventory Trap9."

With a low MOQ model, Mark could have ordered 300 red backpacks. If they sold out in a week, he could place a reorder immediately. Our factory is 3,000 square meters, and we work fast. We can get a reorder ready in 20-30 days.

Why Inventory is Dangerous

- Storage Fees: Warehouses charge by the pallet. Unsold bags eat your money every month.

- Material Degradation: Bags can get moldy or dusty if they sit too long.

- Cash Flow Block: Your money is sitting on a shelf, not in your bank account.

Low MOQ turns this around. You sell, you get cash, you order more. It creates a healthy cycle. You never hold stock that nobody wants.

Can Low MOQ Help Test New Design Trends?

Fashion changes very fast. A hot design today might be boring next month. You need speed to catch the trend.

Yes, low MOQ allows you to test multiple designs simultaneously. You can launch small batches of different colors or styles to see which ones your customers actually prefer before scaling up.

Imagine you have a new idea for a cooler bag. You are not sure if customers want it in blue, green, or black.

If you use a high MOQ factory, you have to guess. You might pick blue. If customers wanted green, you lose the sale.

With low MOQ, you can order 100 blue, 100 green, and 100 black. You put them on your website or take them to a trade show. You watch what happens.

The A/B Testing Strategy

This is standard in software, but you can do it in manufacturing too.

- Launch: Release three small variations.

- Data: See which one sells the fastest.

- Scale: Order 1,000 of the winner. Drop the losers.

Our design team10 at Coraggio consists of 10 people. We help clients do this all the time. We can take one base design and change the colors or the pockets slightly. This lets you test the market accurately.

You are not guessing anymore. You are using real sales data to make decisions. This creates a winning product line.

Does Lower MOQ Always Mean Higher Unit Price?

Everyone wants the lowest price possible. But you worry that ordering small quantities will make the cost per bag too high to make a profit.

Generally, yes, lower quantities mean a slightly higher unit price due to setup costs. However, the total investment is lower, and you avoid the much higher cost of unsold inventory.

Let's be honest about the math. If I set up a machine to cut fabric, it takes my worker 2 hours. If he cuts 100 bags, that 2-hour cost is split by 100. If he cuts 1,000 bags, it is split by 1,000. So, the unit price for the small order is higher.

But you must look at the Total Cost of Ownership11.

The Real Cost Calculation

Scenario A: High MOQ (Cheap Unit Price)

- Order: 1,000 Bags

- Price: $5.00 each

- Total Cost: $5,000

- Sales: You only sell 200 bags.

- Result: You spent $5,000 to make $2,000 (assuming $10 retail). You lost $3,000.

Scenario B: Low MOQ (Higher Unit Price)

- Order: 200 Bags

- Price: $7.00 each

- Total Cost: $1,400

- Sales: You sell 200 bags.

- Result: You spent $1,400. You made $2,000. You made a profit of $600.

In Scenario A, you have a "cheaper" bag, but you lost money. In Scenario B, you paid more per bag, but you made a profit.

Do not be obsessed with the unit price alone. As a startup, your goal is to protect your cash and make a profit on the total project. Paying a little more per bag is like buying insurance against dead stock.

How to Find a Reliable Low MOQ Bag Manufacturer?

Many factories ignore small orders because they want easy money. Finding a partner who cares about your growth is difficult but necessary.

Look for manufacturers with B2B experience who offer OEM/ODM services12. Check if they have flexible production lines13 and a design team10 willing to grow with you, like we do at Coraggio.

Finding the right supplier is the hardest part. You need someone who understands that you are small now, but you will be big later.

At Coraggio, we have helped many small brands grow into big accounts. We know that if we help you with a 200-piece order today, you might order 20,000 pieces in five years.

Checklist for Choosing a Supplier

- Ask About Lines: Do they have specific lines for small orders? We have 120 workers, but we organize them flexibly.

- Check Communication: Do they reply fast? If they ignore you because your order is small, run away.

- Look for Stock Materials14: Ask if they have fabric in stock. This lowers the MOQ significantly.

- Sample Policy15: Are they willing to make samples quickly? A good sample proves quality before you commit.

You need a partner, not just a factory. You need someone who will check the quality, handle the certifications, and deliver on time, even for small orders. This builds trust. When you find a supplier who supports your low MOQ needs, treat them well. They are your engine for growth.

Conclusion

Low MOQ is the safest path for startups16. It saves your cash, reduces inventory risk, and lets you test designs. Start small, validate your market, and grow with a flexible partner.

Understanding Low MOQ can help you minimize financial risks and test the market effectively, crucial for startup success. ↩

Avoiding inventory overstock ensures better cash flow and reduces the risk of unsold products, vital for new businesses. ↩

Maintaining healthy cash flow is essential for operational flexibility and long-term sustainability in startups. ↩

Pivoting designs based on feedback allows startups to meet market demands and improve product offerings. ↩

Understanding financial barriers helps in planning and strategizing for a successful business launch. ↩

Validating product ideas ensures that you invest in products that meet market needs, reducing the risk of failure. ↩

Spreading risk allows businesses to test multiple strategies without committing all resources to one approach. ↩

Reacting to market changes swiftly can give businesses a competitive edge and improve adaptability. ↩

Avoiding the inventory trap prevents financial losses and ensures better inventory management. ↩

A design team helps in creating innovative products and adapting to market trends, crucial for business growth. ↩

Understanding the Total Cost of Ownership helps in making informed financial decisions and optimizing resources. ↩

OEM/ODM services offer customization and flexibility, essential for businesses looking to create unique products. ↩

Flexible production lines allow manufacturers to adapt to different order sizes and product types efficiently. ↩

Using stock materials can lower production costs and reduce lead times, benefiting overall business operations. ↩

A sample policy ensures product quality and customer satisfaction before full-scale production, reducing risks. ↩

Low MOQ minimizes financial risks and allows startups to test the market, making it a safer option for new businesses. ↩