Broken zippers ruin bags1 and damage your reputation. Returns kill profits2 and destroy relationships with your retail clients. Choosing between YKK3 and SBS4 is critical for your brand's long-term success.

YKK is ideal for high-end retail bags5 requiring perfect consistency and brand value. SBS offers comparable durability at a lower cost, making it perfect for high-volume promotional or mid-range products. The best choice depends on balancing your target market's quality expectations with your manufacturing budget.

I have seen many orders delayed because of zipper choices. You need to know the facts before you sign the contract. This guide compares them directly.

What’s the Real Difference Between YKK and SBS Zippers?

You see these logos everywhere, but do you know what they actually mean for your supply chain?

YKK is a Japanese giant known for setting the global standard in precision and smooth operation6. SBS is a Chinese leader offering competitive quality and massive production capacity. Both are reliable, but they serve different market positionings based on brand perception and origin7.

I have worked in the bag industry for 15 years. I have used both brands thousands of times for my clients. The main difference lies in their history and market position. YKK stands for Yoshida Kogyo Kabushikikaisha. They are the safe choice. When a customer sees YKK on a zipper puller, they trust the bag immediately. It is a symbol of quality8. SBS stands for Fujian SBS Zipper. They are the largest zipper manufacturer in China and the second largest in the world. They are the challengers.

In my factory, we see that YKK focuses on perfection9. Every single tooth on the zipper is exactly the same. They control their entire supply chain, even the machines that make the zippers. This means the quality is always consistent. SBS focuses on volume and value10. They have grown very fast because they offer a good product at a better price. Their technology has improved a lot in the last ten years.

For a buyer like you, the difference is often about "face" and branding. If you are selling a luxury backpack in a boutique11, your customer expects YKK. If you are selling a cooler bag in a supermarket, the customer cares about the price and function. SBS works perfectly there. We need to look at the data to understand this better.

Comparison of Brand Positioning

| Feature | YKK | SBS |

|---|---|---|

| Origin | Japan (Global Factories) | China (Global Export) |

| Market Perception | Premium, Industry Standard | Value, High Efficiency |

| Best Application | High-end Retail, Fashion | Promotional, Mass Market |

| Innovation Focus | Precision Engineering | Production Volume |

I always tell my clients to think about the end user. Does the user check the zipper brand? If yes, use YKK. If they just want it to zip, SBS is a smart business move.

Which Zipper Performs Better for Daily Use and Durability?

A zipper that sticks or breaks will destroy your customer's trust in your brand immediately.

Both brands pass standard international durability tests12 for strength and cycle life. YKK generally maintains smoother operation over a longer period. SBS is incredibly tough but might feel slightly stiffer when brand new. For heavy-duty use, both perform well, but YKK has a slight edge in consistency.

We need to talk about how the zipper feels. This is the "hand feel." When you pull a YKK zipper, it feels like butter. It is smooth right out of the box. This is because they polish the metal teeth and mold the plastic teeth with high precision. For a cosmetic bag or a laptop backpack, this smooth feeling is part of the luxury experience.

SBS zippers are very strong. In terms of pure strength, they are often equal to YKK. You can pull them hard, and they will not burst open. However, I have noticed that SBS zippers can feel a little stiff when you first use them. They need a "break-in" period. After you zip and unzip them twenty times, they become smooth. For a duffle bag or a heavy-duty tool bag, this stiffness is not a problem. It actually makes the bag feel rugged and tough.

There is also the issue of the "finish." The plating on the metal sliders13 needs to stay on. In my experience, YKK plating lasts a very long time without scratching. SBS is good, but on cheaper models, the color might fade faster if the user is rough with it. We always check the lateral strength14. This is how much force it takes to pull the zipper tape apart from the sides. Both brands meet the ISO standards here.

Performance Breakdown by Zipper Type

| Performance Metric | YKK Characteristics | SBS Characteristics |

|---|---|---|

| Initial Smoothness | Very High | Medium to High |

| Lateral Strength | Excellent | Excellent |

| Color Fastness | High Consistency | Good (Varies by batch) |

| Tape Quality | Soft and Flexible | Durable and Stiff |

If your product is a promotional tote bag, the user will not notice the difference in smoothness. If it is a $100 travel bag, they will notice.

How Do YKK vs SBS Zippers Compare on Cost and Lead Time?

Your profit margin relies on material costs, and zippers are a surprisingly large part of that equation.

YKK zippers typically cost 20% to 40% more than SBS zippers depending on the model. Furthermore, YKK often has longer lead times due to high demand15. SBS offers a significant price advantage and faster production turnaround, which is crucial for urgent B2B orders.

Price is usually the deciding factor for my clients. Let’s be honest about the numbers. If you are ordering 50,000 cooler bags, a 20 cent difference per zipper is $10,000. That is pure profit you are losing if you choose the wrong brand. YKK commands a premium price. You are paying for the brand name and the Japanese management systems. For B2B orders where the target price is low, YKK can break the budget.

SBS provides a massive cost advantage16. Since my factory is in China, and SBS is based in China, the logistics are cheaper. We don't have to import anything. The price of an SBS zipper is usually 30% cheaper than a comparable YKK zipper. This allows you to spend that money on better fabric or better packaging.

Time is also money. YKK is famous, so everyone wants them. Their factories are often booked out. Sometimes, we have to wait 3 to 4 weeks just to get the zippers delivered to our factory. This can delay your shipment. SBS is very fast. They are hungry for business. They can often deliver customized zippers in 1 to 2 weeks. If you have a rush order for a trade show or a holiday promotion, SBS is the lifesaver.

Cost and Time Matrix

| Factor | YKK | SBS |

|---|---|---|

| Average Cost | High ($$$) | Moderate ($$) |

| Standard Lead Time | 20-30 Days | 7-15 Days |

| Custom Color Fee | High | Low |

| Minimum Order Qty | Strict / High | Flexible |

I recently had a client from Canada who needed 10,000 backpacks in 45 days. YKK said the zippers would take 30 days. We switched to SBS, got the zippers in 10 days, and shipped the order on time.

Which Zipper Is Less Likely to Cause Returns or Complaints?

Returns hurt your bottom line and damage your relationship with big retail buyers.

YKK has a near-zero defect rate17, which is why luxury brands prefer it to minimize risk. SBS has improved quality control significantly and rarely fails in standard applications. However, for complex bag designs or high-tension areas18, YKK remains the safer option to prevent end-user complaints.

Risk management is a big part of your job. When you buy from overseas, you want to sleep well at night. You don't want to worry about zippers breaking. YKK is the "safe" option. If a customer complains about a bag, and they see a YKK zipper, they usually blame the bag design, not the zipper. If they see a generic zipper or a brand they don't know, they blame the "cheap quality."

In my factory, we have strict QC. We check the zippers when they arrive. With YKK, we almost never find a bad one. Maybe one in ten thousand. With SBS, the quality is also very good now. Five years ago, it was different. But today, SBS has automated lines too. We rarely see failures with SBS on standard nylon or coil zippers.

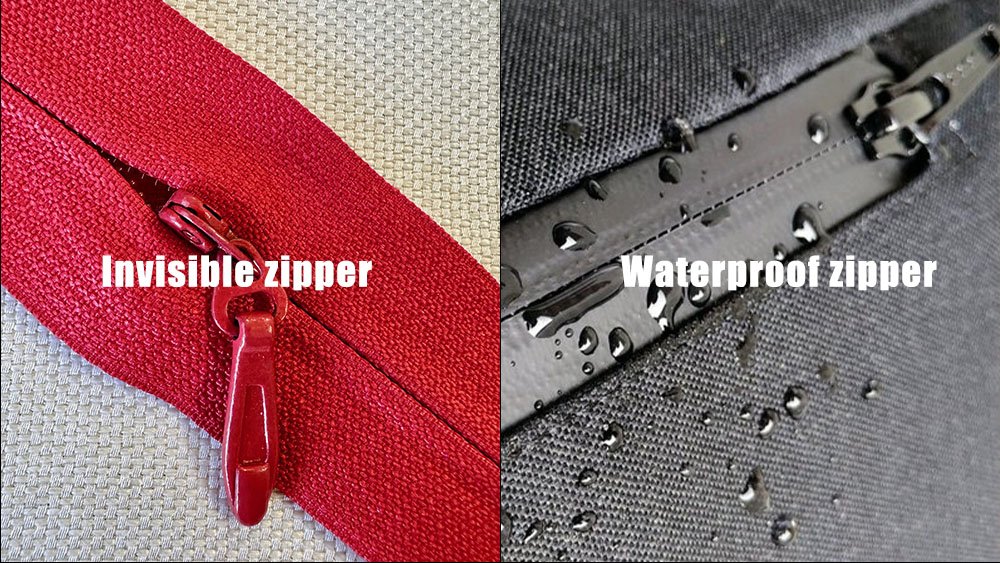

However, there is a risk with "invisible" zippers or waterproof zippers19. These are harder to make. For these technical items, YKK is still superior. If you are making a waterproof cooler bag, a leak is a disaster. I would recommend YKK for that specific function. For a standard school backpack, SBS is safe. The return rate is not noticeably different for standard products.

Risk Assessment by Product Category

| Bag Type | Recommended Brand | Reason for Choice |

|---|---|---|

| Luxury / Designer | YKK | Brand Prestige, Zero Defect |

| Outdoor / Technical | YKK | Reliability in Harsh Conditions |

| Promotional / Gift | SBS | Cost Efficiency, Good Enough |

| Supermarket Retail | SBS | High Volume, Price Sensitive |

You have to match the component to the warranty. If you offer a lifetime warranty, use YKK. If it is a promotional item used for a few months, SBS is the smart choice.

What Should B2B Buyers Test Before Confirming a Zipper Supplier?

You cannot rely only on brand names; you must verify the physical product yourself.

Request samples of the exact zipper model installed on your specific fabric. Test the smoothness, the locking mechanism of the puller, and the lateral strength14. Check how the zipper tape reacts to your bag's curves. Never approve a bulk order without a physical "gold sample" review20.

Do not just say "I want YKK" or "I want SBS" on the purchase order. You need to be specific. There are many models: #3, #5, #8, #10. There are nylon coils, plastic molded, and metal teeth. You must test the specific combination.

I always send my clients a "pre-production sample." When you get this, you need to abuse the zipper. Pull it fast. Pull it slow. Jerk it sideways. See if the fabric gets caught in the slider. This often happens not because the zipper is bad, but because the stitching is too close to the teeth. You need to check this design flaw before mass production.

Also, check the color matching. The zipper tape is made of polyester. Your bag might be made of canvas or nylon. Different materials absorb dye differently. An SBS black might be slightly different from a YKK black. You need to see this under the light. We call this the "lab dip" approval. Make sure the puller (the metal tab) is strong. Sometimes the zipper is fine, but the puller snaps off.

The Buyer’s Checklist for Zippers

| Test Action | What to Look For |

|---|---|

| The Cycle Test | Zip and unzip 50 times. Does it get smoother or harder? |

| The Fabric Bite | Does the inner lining get stuck in the slider? |

| The Puller Strength | Pull the tab hard. Does the metal bend or break? |

| The Curve Check | Does the zipper ripple or wave around the corners of the bag? |

I help my clients do these tests in our factory lab. But you should also do them in your office. Your hands are the best judge. If it feels cheap to you, it will feel cheap to your customer.

Conclusion

Choose YKK for premium retail bags where brand image matters. Choose SBS for promotional or high-volume orders to save costs. Always test samples before production to ensure quality.

Understanding how zipper failures ruin products helps you justify investing in better components and reduce costly product returns. ↩

Seeing the hard financial impact of returns will help you prioritize quality decisions that protect your margins and brand relationships. ↩

Learn YKK’s history, technology, and quality standards so you can justify its higher cost and decide when it’s worth using for your brand. ↩

Understand who SBS is, their quality standards, and pricing so you can confidently decide if they’re the right value choice for your bag production. ↩

Learning the expectations for premium bags guides you in selecting hardware that matches luxury price points and brand image. ↩

Exploring how precision engineering affects feel and durability helps you choose zippers that delight customers instead of frustrating them. ↩

Understanding how origin and perception affect branding ensures your component choices support your target market strategy. ↩

Learning how hardware branding signals quality helps you decide when to showcase zipper brands to boost buyer trust. ↩

Seeing how perfectionism in production translates to reliability clarifies when paying a premium truly reduces risk. ↩

Understanding volume-based manufacturing lets you leverage lower costs and faster delivery for large orders. ↩

Reviewing typical luxury backpack specs helps you align your materials with high-end retail expectations. ↩

Knowing the relevant tests enables you to request proper certifications and compare suppliers objectively. ↩

Understanding plating performance helps you avoid premature wear that leads to complaints and returns. ↩

Exploring lateral strength testing shows you how to evaluate zippers for demanding load and stress conditions. ↩

Seeing how demand creates bottlenecks helps you plan timelines and choose suppliers that fit your schedule. ↩

Discovering real cost differences helps you reallocate budget to fabrics, features, or margins without hurting quality. ↩

Learning the impact of defect rates clarifies why premium components can save money over the product lifecycle. ↩

Understanding zipper needs in stressed areas helps you prevent failures in critical points of your products. ↩

Exploring waterproof zipper technology helps you avoid leaks and performance issues in outdoor or cooler bags. ↩

Learning how to use a gold sample protects you from surprises in mass production quality and feel. ↩