You found a supplier with a low price, but the final bill is huge. Why? Often, it isn't the price per bag. It is the cost of confusion.

Miscommunication1 increases sourcing costs2 through repeated sampling3, production rework4, and wasted materials5. When specifications6 regarding size, fabric, or logos are unclear, factories make mistakes. Correcting these errors leads to delays, rush fees, and expensive air freight, destroying your profit margins.

I have seen this happen many times in my 15 years at Coraggio. A buyer thinks they ordered one thing, and the factory makes another. This gap in understanding is expensive. Let’s look at how to stop this bleeding.

What “Miscommunication” Looks Like in B2B Bag Sourcing?

You send an email. The factory says "OK". But do they really understand what you want? You might be surprised by the result.

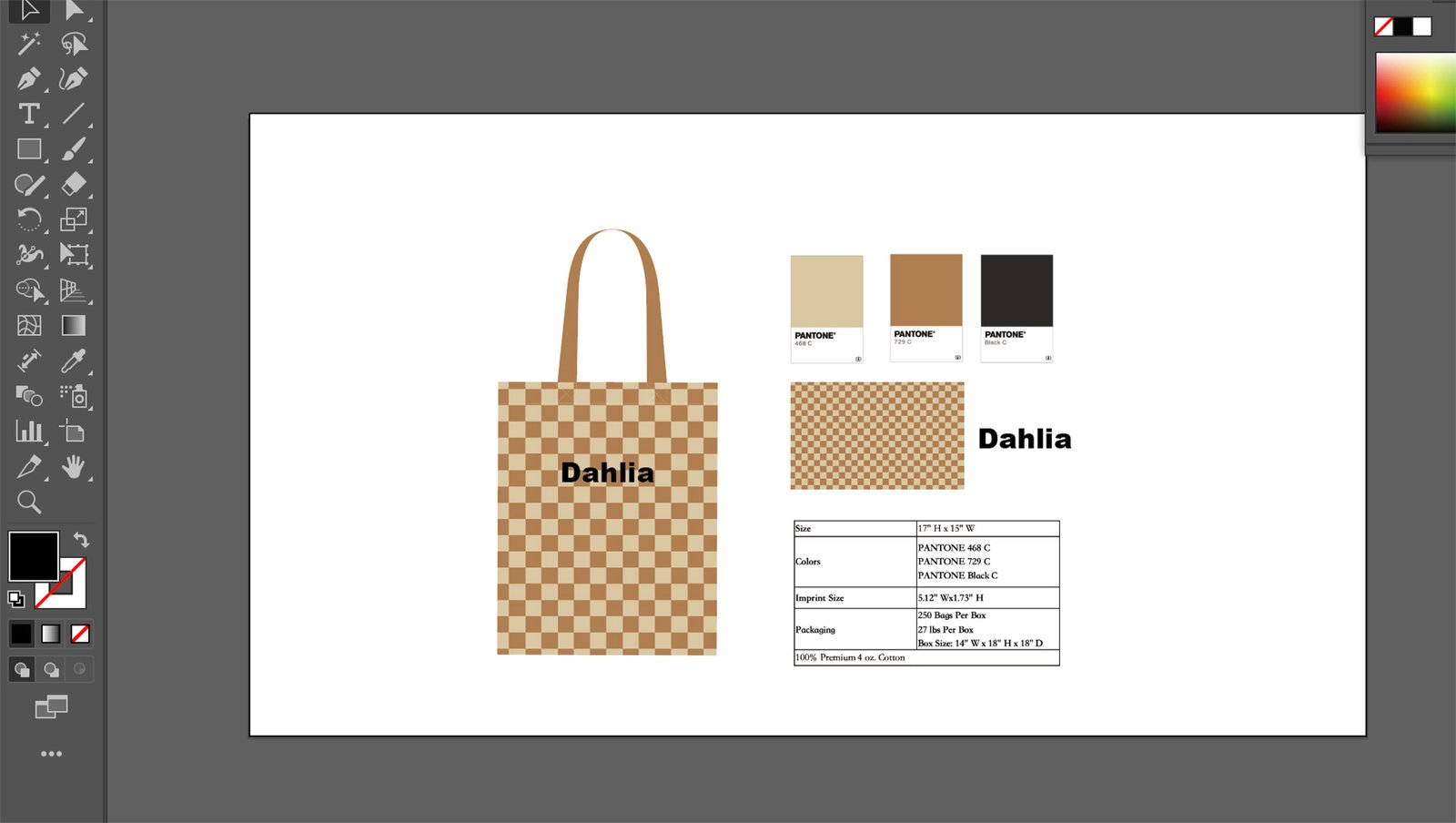

In bag sourcing, miscommunication looks like vague descriptions like "standard size" or "blue fabric." Without Pantone codes7 or technical drawings8, the factory guesses based on their experience, not your requirements. This gap between expectation and reality is where money is lost.

I want to tell you a story about a client from Canada. He wanted a "heavy duty" tote bag. He wrote this in an email. To him, "heavy duty" meant a thick 16oz canvas that could stand up on its own. However, he did not specify the weight. My sales team saw "heavy duty" and thought about the standard market quality, which is 12oz. We made the sample. We sent it to him.

He rejected it immediately. He said it felt "cheap." We had to buy new fabric. We had to make a new sample. We had to pay for shipping again. This cost us two weeks of time and double the sample fees. This is what miscommunication looks like. It is rarely a total lack of language. It is usually a lack of detail.

In the bag industry, words are not precise enough. A "large" backpack means something different in China than it does in North America. A "soft" handle is subjective. When you rely on adjectives instead of numbers and codes, you invite the factory to guess. If they guess wrong, you pay for it.

Here is a breakdown of common vague terms versus clear terms:

| Vague Term (Bad) | Clear Term (Good) |

|---|---|

| "Make it blue" | "Pantone 289C" |

| "Standard size" | "35cm W x 40cm H x 10cm D" |

| "Strong material" | "600D Polyester with PVC backing" |

| "Print my logo" | "Silk screen print, 10cm wide, centered 5cm from top" |

Where Costs Increase: Materials, Specs, Sampling, and Production?

You might think the price on the invoice is final. But errors add hidden fees quickly. These costs hide in every step of the process.

Costs increase in four main areas: wasted materials5 from wrong orders, incorrect specifications6 requiring new tooling, repeated sampling3 rounds, and halted production lines. Every time a question is asked during production instead of before, labor hours and material costs go up.

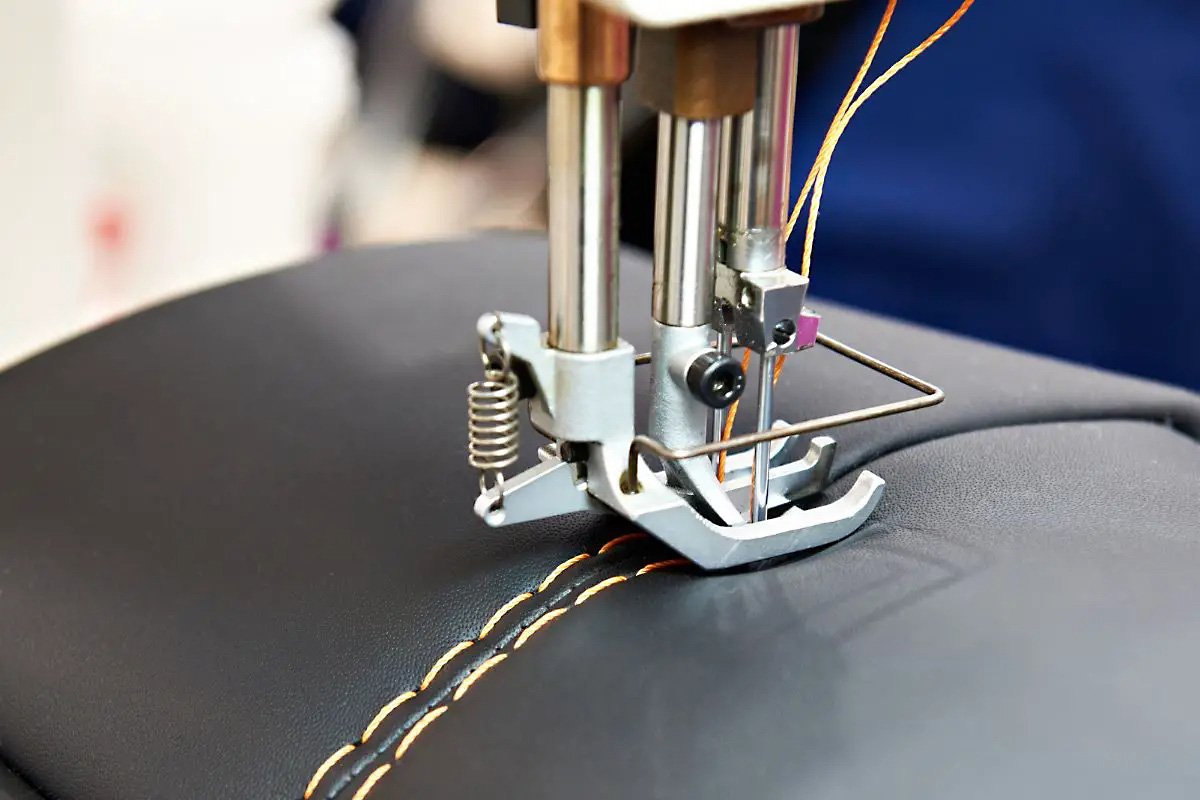

Let's look deeper into where your money goes when communication fails. The biggest loss usually happens with materials. In our factory, we order fabric based on your confirmed order. If you realize the color is wrong after we cut the fabric, that material is waste. We cannot return cut fabric to the mill. Someone has to pay for that loss. Usually, the supplier will try to pass that cost to you, or they will increase your price on the next order to recover the loss.

Then there is the sampling3 cost. A sample is not free for us. It takes a skilled master hours to make a pattern and sew a single bag. If you change the specs because you forgot to mention a pocket, we have to start over. One sample might cost $100. Three rounds of samples cost $300. But the bigger cost is time.

Production specifications6 also drive costs. If you do not specify the stitching method, we might use a standard stitch. If you actually wanted reinforced cross-stitching for heavy loads, we have to stop the machines. We have to reset the production line. This downtime costs money.

Here is how costs pile up at each stage:

- Sampling Stage: Multiple courier fees and sample development charges.

- Material Purchase: Wrong fabric density or color results in "dead stock" that cannot be used.

- Cutting Stage: If the size is wrong by 2cm, the metal cutting mold9 (which costs money) must be scrapped and remade.

- Sewing Stage: If a label is placed wrong, workers must rip seams open to fix it. This doubles the labor cost per bag.

How Miscommunication Triggers Rework, Delays, and Extra Fees?

A mistake in the beginning is cheap. A mistake at the end is a disaster. The later you find an error, the more it hurts.

When errors are found late, you face rework costs to fix seams or logos. Worse, this causes delays. You might miss your sales window or pay huge fees for air freight instead of sea shipping to get goods on time.

Imagine this scenario. We finish 5,000 cooler bags for you. The production is done. Then, your quality inspector10 arrives. He checks the bags and sees the logo is 2cm too low. You did not send a layout drawing, so the workers put it where it looked best to them. Now, you have a choice. You can accept the bags as they are, or you can ask for rework.

If you ask for rework, we have to unpack every bag. We have to unstitch the pocket. We have to make a new pocket with the correct logo position. We have to sew it back on. This is huge manual labor. It takes days.

This leads to the most painful cost: The Delay.

You planned to sell these bags for a summer promotion. Because of the rework, the bags are two weeks late. The ship has already left the port. The next ship is in 10 days. That is too late for your store launch. Now, you must use air freight.

Shipping 5,000 bags by sea might cost $2,000. Shipping them by air might cost $15,000. That $13,000 difference comes directly out of your profit. It turns a profitable deal into a loss. All of this happens because the logo position was not confirmed in a drawing before we started sewing.

Also, rushing leads to more mistakes. When workers rush to fix a problem, quality often drops. Stitches get messy. Threads are not trimmed. You might solve the logo problem but create a quality problem. It is a vicious cycle.

Which Details Buyers Must Confirm: Size, Fabric, Logo, Packaging?

You cannot just say "make it nice." You must define what "nice" means for every part. Small details cause big arguments.

To avoid costs, buyers must confirm four key details: exact dimensions (length, width, gusset), specific fabric density and backing, logo placement11 and method (print vs. embroidery), and packaging requirements12 like hangtags or polybag warnings.

I advise all my clients to focus on a few critical areas. These are the places where 90% of disputes happen.

1. Size and Tolerance You must give the Length, Height, and Width (Gusset). But you must also agree on tolerance. In sewing, a 0.5cm or 1cm difference is normal. If you need exact precision, you must say so. If a bag is too small, your product might not fit inside.

2. Fabric Specification "Polyester" is not enough. Is it 600D? 420D? Is the backing PVC (stiff) or PU (soft)? This changes the feel and cost of the bag completely. We once had a client reject a shipment because the bag had a strong plastic smell. This was because they chose PVC backing but didn't know it smells when fresh. If they told us they wanted odorless, we would have used PU.

3. Logo Execution This is very important for your brand. You must define the size of the logo. You must define the colors using Pantone numbers. You must also choose the method. Silk screen is cheap but can crack. Heat transfer is colorful but costs more. Embroidery looks premium but can pucker thin fabric.

4. Packaging Do you need a barcode sticker? Do you need a warning label on the plastic bag? Do you need a "Made in China" tag? If these are missing, your goods might get stuck at Customs in Canada or the USA. Adding a sticker after the goods are packed in cartons is very expensive. We have to open every carton and handle every bag again.

Here is a checklist for your Spec Sheet:

- Dimensions: L x H x D (cm/inch)

- Material: Type, Weight, Coating, Color

- Handle: Length, Width, Material type (webbing/fabric)

- Logo: Artwork file, Dimensions, Position, Technique

- Accessories: Zipper type (nylon/metal), Puller type, Buckles

- Packing: Qty per carton, Carton markings, Hangtags

How to Prevent Costly Errors: A Buyer–Supplier Checklist (FAQ)?

You want to save money and sleep better. The solution is a simple document. It protects you and the factory.

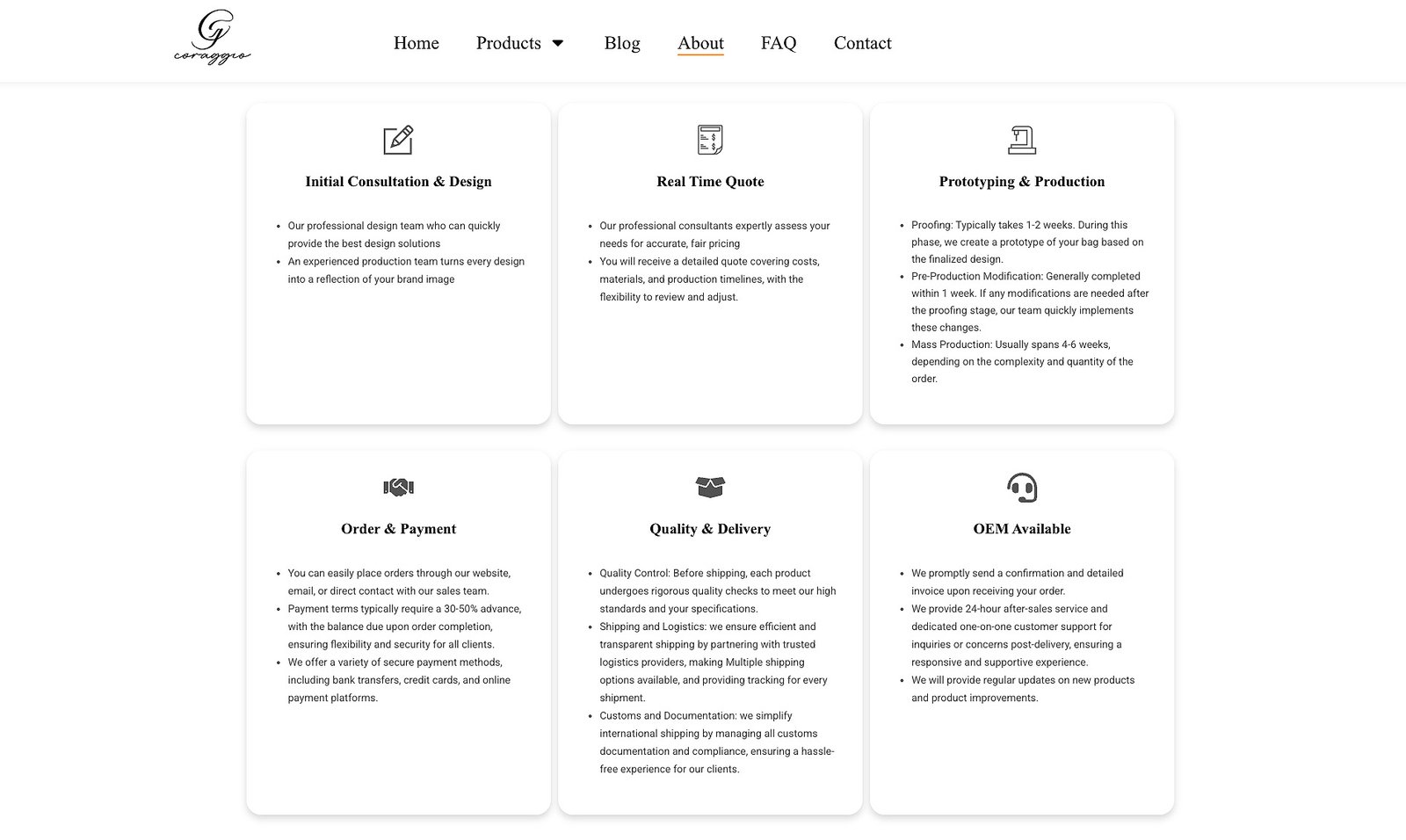

Prevent errors by using a detailed Tech Pack or Specification Sheet. Require a pre-production sample13 (PPS) sign-off. Create a checklist that forces both the buyer and the factory to confirm every material, color, and dimension in writing before mass production begins.

How do we fix this? At Coraggio, we use a strict confirmation process. We do not like guessing. Guessing loses money.

First, we create a Tech Pack or a detailed Quotation Sheet. This lists every detail we discussed. I ask you to read it carefully. If the handle length says 60cm, but you wanted 70cm, you must catch it here. It costs zero dollars to fix a number on a paper.

Second, we make a Pre-Production Sample (PPS). This is the "Gold Standard." It is the exact bag we will make 10,000 times. We send this to you. You must touch it, measure it, and test it.

Third, the Sign-Off. You sign a tag on the sample and send it back to us (or approve photos if you trust us). Once you sign, the standard is set. If the final production does not match this sample, Coraggio pays for the fix. If the production matches the sample, but you decide you don't like the color anymore, you pay for the fix. This fairness makes everything clear.

Here is a simple FAQ checklist to ask yourself before you send the deposit:

Q: Do I have a drawing with measurements? A: If not, ask the factory to make one for approval.

Q: Did I pick a specific Pantone color? A: "Dark Blue" is not a color. "Pantone 289C" is a color.

Q: Did I approve the final sample? A: Never start mass production without seeing a sample.

Q: Is the packaging clear? A: Ensure the factory knows how to pack the goods to avoid damage during shipping.

By using this checklist, you force the communication to be clear. You remove the "I thought you knew" excuse. This is how smart buyers like Mark operate. They spend time on the details upfront so they don't spend money on problems later.

Conclusion

Clear communication reduces bag sourcing costs2 by preventing rework, material waste, and expensive shipping delays14. Always use detailed spec sheet15s and signed samples to protect your profit.

Understanding the impact of miscommunication can help you avoid costly mistakes in sourcing. ↩

Learn strategies to effectively reduce sourcing costs and improve your bottom line. ↩

Discover how effective sampling can save time and money in the production process. ↩

Understanding the causes of rework can help you implement better practices and save costs. ↩

Explore methods to minimize waste and improve efficiency in your production process. ↩

Clear specifications can prevent costly errors and ensure product quality. ↩

Learn how Pantone codes ensure color accuracy in your products. ↩

Technical drawings provide clarity and precision, reducing the risk of errors in production. ↩

Learn about cutting molds and their importance in achieving precise product dimensions. ↩

Quality inspectors ensure that products meet specifications and standards, preventing costly errors. ↩

Proper logo placement enhances brand visibility and product appeal. ↩

Understanding packaging requirements can prevent delays and ensure compliance. ↩

A pre-production sample helps confirm product specifications before mass production. ↩

Identifying causes of shipping delays can help you plan better and avoid extra costs. ↩

A spec sheet outlines all product details, reducing misunderstandings and errors. ↩