Late deliveries destroy your reputation and ruin your sales season. Are you tired of suppliers missing deadlines? I will show you how to guarantee on-time delivery for bulk orders every time.

Controlling lead time1 requires three steps: precise material planning2 before production, visual monitoring3 during manufacturing, and proactive communication4 with buffer periods5. This systematic approach ensures raw materials arrive early, production lines run smoothly without bottlenecks, and finished goods ship exactly when promised.

Many buyers think delays are normal when buying from China. They are not. In my 15 years running Coraggio, I learned that delays come from bad management. You need a partner who understands the process. I want to share exactly how we fix this.

How Does Accurate Planning Before Orders Prevent Delays?

Waiting for fabric stops the whole factory. It costs you money and time. We stop this problem before it starts by planning every detail.

The most effective way to prevent delays is to calculate material needs immediately. We order core materials early and track their arrival strictly. This prevents the "waiting for parts" problem that causes most production delays6.

The Importance of Pre-Production Planning

The biggest reason for delay happens before we sew a single bag. It happens because the materials are not ready. At Coraggio, we have a strict rule. We do not guess. We plan.

When I receive an inquiry for 50,000 cosmetic bags, my team starts work immediately. We do not just look at the design. We look at the Bill of Materials (BOM)7. We identify which parts are standard and which parts are custom.

Core Material Control

We focus on the "Core Materials8." For cosmetic bags, this is usually the outer fabric (like PU leather or eco-friendly recycled polyester) and the zipper. These items take the longest to make.

If a supplier tells you the lead time1 is 30 days, but they order the fabric on day 10, they will fail. We order materials on day 1.

Here is how we structure the timeline for a typical bulk order:

| Stage | Action Item | Time Allocation | Goal |

|---|---|---|---|

| Analysis | Review design and confirm BOM | Day 1-2 | Identify long-lead items |

| Ordering | Place orders for fabric and zippers | Day 3 | Secure raw materials early |

| Tracking | Daily check with material vendors | Day 4-15 | Ensure materials arrive on time |

| Inspection | Check material quality upon arrival | Day 16 | Avoid bad materials stopping the line |

Avoiding the "Missing Piece" Trap

I remember one order from a new client. He told me his previous factory delayed his order by three weeks because they ran out of zipper pullers. That is a small part. But without it, the bag is useless.

We avoid this by checking inventory first. We have a 3,000 square meter facility. We keep stock of common items. For custom items, we pay deposits early to lock in the delivery date. This precise planning ensures that when the production line starts, it does not stop.

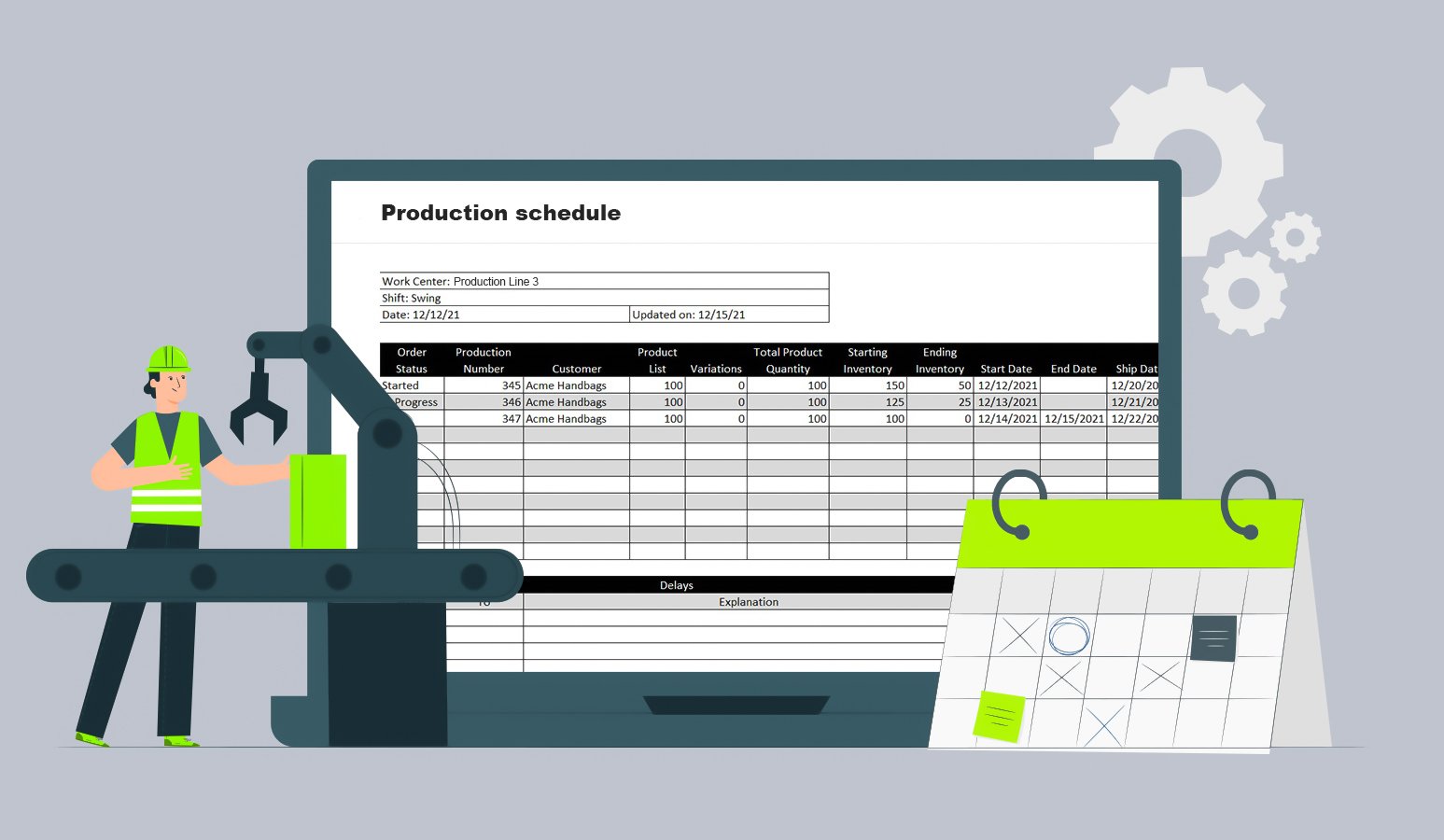

Why Is Visual Management Crucial During Production?

You cannot fix what you cannot see. Hidden problems cause panic at the end of the month. We make every step visible to keep control.

Visual management means using charts and boards on the production line. We monitor progress hourly. This keeps the workflow balanced and identifies quality issues instantly, preventing massive rework that delays shipment.

Seeing the Workflow Clearly

Once the materials arrive, the real work begins. We have 8 production lines and 120 workers. If we do not watch closely, chaos happens.

We use a method called "Visual Management.9" This sounds technical, but it is simple. We put big whiteboards at the end of every line. These boards show the target for the hour and the actual output.

If the target is 100 cosmetic bags per hour, but the line only makes 80, we see it immediately. We do not wait until the end of the day. The line leader goes to find the problem. Maybe a sewing machine is broken. Maybe a worker is new and needs help. We fix it right then.

Balancing the Process

Making a cosmetic bag has many steps. Cutting, printing, sewing the zipper, sewing the lining, and packing. The line must be balanced.

If the cutting team is too fast, piles of fabric block the floor. If the sewing team is too slow, the packers have nothing to do.

We use critical thinking to balance this. We assign more experienced workers to the hard parts. We use automated cutting machines to keep up with the sewing teams. This flow keeps the speed constant.

Quality Control as a Time Saver

Many people think checking quality takes time. They think it slows down production. I disagree. Fixing mistakes takes time. Doing it right the first time saves time.

We have quality checkpoints10 at every stage.

- Cutting Check: Is the panel the right size?

- Semi-finished Check: Is the logo printed correctly?

- Finished Check: Does the zipper work smoothly?

If we find a bad logo on step 2, we discard that piece. We do not sew it into a bag. If we wait until the end, we have to rip the bag open to fix it. That causes huge delays. By catching errors early, we ensure the final packing stage is fast and smooth.

How Do Communication and Buffer Time Save the Delivery Date?

Silence from a supplier is scary. You worry about the shipment and your money. We talk to you before you have to ask.

We maintain active communication throughout the project. We also build backup plans and reserve time buffers for unexpected events. This strategy ensures that even if something goes wrong, your delivery date remains safe.

Being Proactive, Not Reactive

I know that Mark, like many buyers, hates inefficient communication. You send an email and wait three days for a reply. That is stressful.

At Coraggio, I insist on proactive updates. You should not have to chase me. I should tell you what is happening. We send weekly reports. These reports include photos of the production line. You can see your bags being made.

If there is a problem, I tell you immediately. But I do not just bring problems. I bring solutions.

For example, if a storm delays a fabric truck, I will tell you: "The truck is late due to weather. But we will work overtime on Saturday to catch up." This builds trust. You know I am handling it.

The Power of the Buffer

In manufacturing, things go wrong. Machines break. Workers get sick. Power goes out. This is reality.

The only way to beat reality is with a "Buffer." This is extra time we add to the schedule.

If I calculate that I need 25 days to make your order, I will quote you 30 days. That 5-day buffer is my safety net.

- Scenario A: Everything goes perfect. I finish in 25 days. I ship early. You are happy.

- Scenario B: A machine breaks and takes 2 days to fix. I finish in 27 days. I still ship on time. You are happy.

Backup Plans for Critical Risks

We also have Plan B for everything.

- Power Failure: We have backup generators.

- Worker Shortage: We have a flexible team that can move between lines.

- Material Defect: We order 3% extra material so we do not run out if some fabric is bad.

This risk management11 is why we can serve large clients in North America and Europe. We do not just hope for the best. We prepare for the worst. This ensures your goods arrive before your sales season starts.

Conclusion

To control lead time1, we must plan materials early, visualize the production flow12, and communicate openly with safety buffers. This protects your business.

Understanding lead time is crucial for managing production schedules and ensuring timely deliveries. ↩

Effective material planning is key to avoiding delays and optimizing production processes. ↩

Visual monitoring helps identify issues in real-time, ensuring smooth production and timely deliveries. ↩

Proactive communication builds trust and keeps all parties informed, reducing anxiety and delays. ↩

Buffer periods provide a safety net for unexpected delays, ensuring projects stay on track. ↩

Identifying causes of delays can help businesses implement strategies to avoid them. ↩

A BOM is essential for understanding material requirements and preventing production delays. ↩

Core materials are vital for production; managing them effectively prevents bottlenecks. ↩

Discover how this Lean manufacturing principle transforms complex data into clear visual signals that prevent costly production bottlenecks. ↩

Quality checkpoints ensure that errors are caught early, saving time and resources. ↩

Risk management is essential for anticipating challenges and ensuring smooth operations. ↩

Optimizing production flow is key to increasing efficiency and meeting delivery deadlines. ↩