You need custom felt bags for your business, but manufacturing errors can ruin your budget. Are you worried about poor stitching or wrong materials destroying your brand's reputation with your customers?

To make felt tote bags in bulk, first select the specific felt thickness (usually 3mm) and weight. Confirm the design via a physical sample. Then, the factory cuts fabric, prints logos, stitches handles with reinforcement, and conducts strict QC before packaging. This ensures durability and consistency.

I have seen many buyers struggle with the production process because they do not know what happens inside the factory. This lack of knowledge leads to delays and quality issues. I want to show you exactly how we manufacture these bags at Coraggio. This way, you can order with confidence and know what to look for.

What Felt Material Is Best for Felt Tote Bags in Bulk Orders?

Choosing the wrong felt leads to floppy, cheap-looking bags that customers will throw away. Do you know which density ensures your bags hold their shape perfectly and carry heavy loads?

The best material for tote bags is usually 3mm thick polyester felt1 with a density of 400-600gsm2. This provides structure without being too heavy. For eco-friendly brands, Recycled PET (RPET) felt3 is the ideal choice as it is durable, sustainable, and performs just like regular polyester.

In my 15 years of experience at Coraggio, I see clients make mistakes here often. They pick thin felt to save a few cents. But 2mm felt collapses4 when you put items inside. It looks cheap. You need 3mm or 4mm thickness for a bag that stands up on its own.

We must also talk about the material source. Most buyers now want eco-friendly products. We use RPET felt. This material comes from recycled plastic bottles. It is strong and good for the planet. It feels soft but is very tough. You also need to decide on the weight (GSM). If the weight is too low, the bag feels like paper. If it is too high, the bag is heavy before you put anything in it.

Here is a simple breakdown of felt choices I recommend for B2B orders:

| Felt Thickness | Recommended Usage | Pros | Cons |

|---|---|---|---|

| 2mm | Small pouches, cosmetic bags | Very cheap, flexible | No structure, looks low-end for totes |

| 3mm (Standard) | Shoppers, daily tote bags | Good balance, stands upright | Slightly more expensive than 2mm |

| 4mm+ | Laptop sleeves, heavy-duty storage | Very rigid, highly protective | Hard to sew complex shapes, heavy |

You must also check the color consistency5. Felt absorbs dye differently than cotton. I always send a swatch card6 to my clients first. You need to see the grey or the black with your own eyes. This prevents surprises when the container arrives.

How Does a Factory Create Samples for Custom Felt Tote Bags?

Skipping the sample stage is a gamble you cannot afford in international trade. How do you ensure the final product matches your vision before spending thousands of dollars on mass production?

A factory creates a sample by cutting the specific felt color and stitching it to your dimensions. We test handle length, pocket placement, and logo printing. You must approve this physical prototype to lock in the sewing quality and load-bearing capacity before mass production begins.

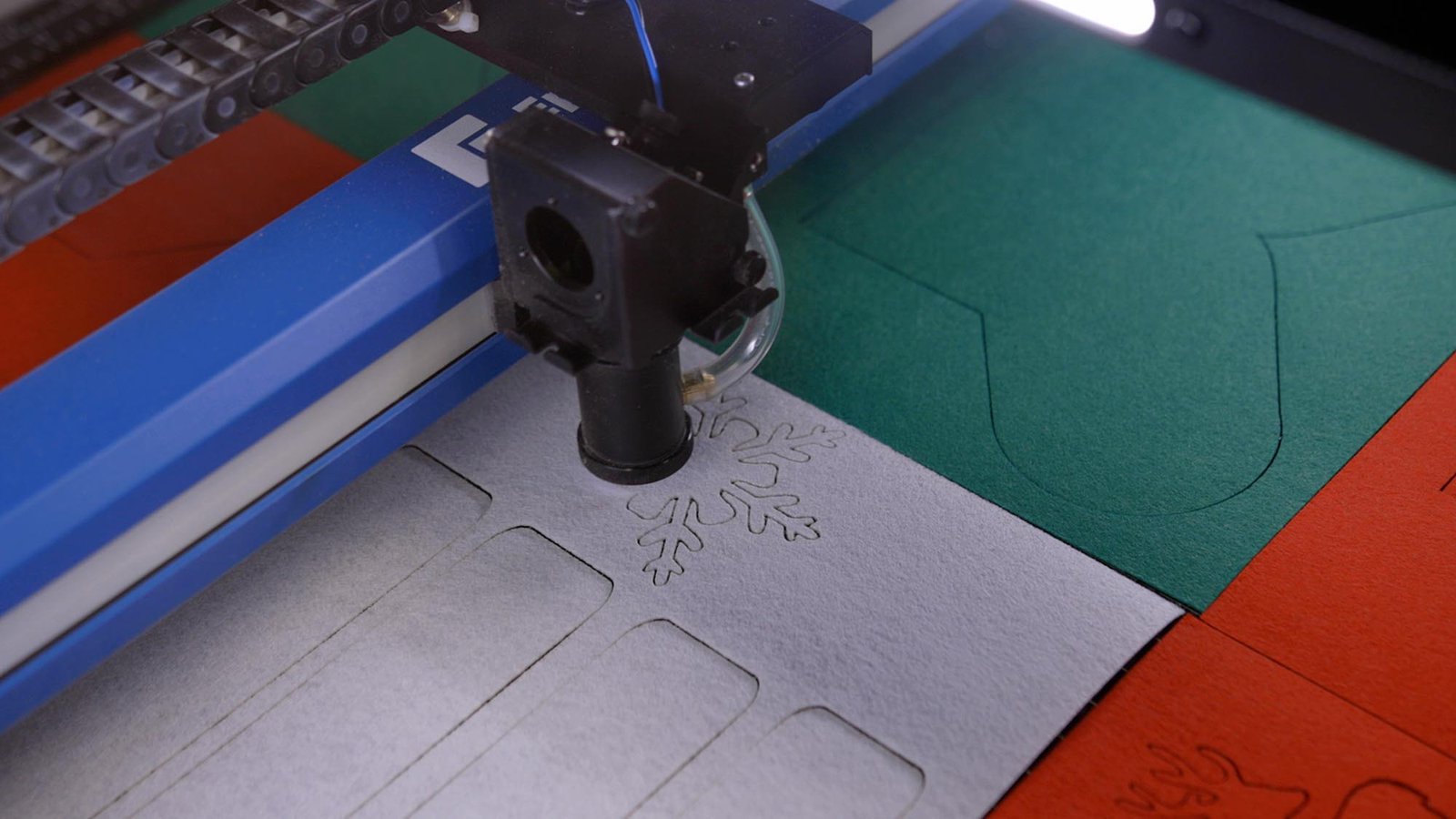

The sample is your contract. When I make a sample for a client, I check the paper pattern first. We determine the size and the shape. We cut the material by hand or by laser for the sample. Laser cutting is very important for felt. It seals the edges. If you use a knife die, the felt might fray later. Laser keeps it clean.

Next, we look at the sewing details. We decide on the binding. Some clients want a folded edge. Others want a raw laser-cut edge7. We also check the handles. I always recommend "X" stitching on the handles8. This is a box with an X inside. It makes the handle very strong.

During the sample phase, we also test the logo. Felt is fuzzy. Small text does not print well on felt. I usually suggest laser engraving or a leather patch for logos. If you want silk screen printing, the lines must be thick.

The sample process usually takes 5 to 7 days. I send photos to the client first. Then I send the physical bag. You must put things in it. Carry it around. See if the straps are too long or too short. Once you say "yes" to the sample, we use that exact bag as the "Gold Standard" for the factory workers.

What Are the Key Manufacturing Steps for Bulk Felt Tote Bags?

Production delays often happen due to disorganized workflows in the factory. Do you understand the specific steps required to keep your order on schedule and consistent?

The key steps are material cutting, logo application, component assembly, and final stitching. First, large felt rolls are die-cut or laser-cut. Then, logos are printed or embroidered. Workers sew the body and handles. Finally, the bags are cleaned and inspected before packing.

Mass production is different from making one sample. We need speed and accuracy.

Step 1: Cutting We bring in large rolls of felt. We do not cut one by one. We use a hydraulic press with a large metal die9. This cuts through many layers of felt at once. It ensures every piece is the exact same size. For complex shapes, we use automated laser cutters10.

Step 2: Logo Application This is a critical step. We apply the logo before we sew the bag. If we try to print on a finished bag, the surface is not flat. The print will look bad. If you choose a leather label, we sew it on the felt panel now.

Step 3: Sewing Assembly We have 8 production lines at Coraggio. The workers work in a line. One person sews the side seams. The next person sews the bottom gusset. The last person attaches the handles. This division of labor makes us fast. We can produce thousands of bags quickly.

Step 4: Trimming and Cleaning Felt produces dust when cut. After sewing, the bags might have loose threads or dust. We have a team that cleans the bags. They trim the threads. They use air blowers to remove the dust.

Here is how the timeline usually looks for a standard order:

| Production Phase | Time Estimation | Key Activity |

|---|---|---|

| Material Prep | 5-7 Days | Sourcing felt rolls, checking fabric quality |

| Cutting & Printing | 3-5 Days | Die cutting panels, printing logos |

| Sewing | 10-15 Days | Assembly line stitching |

| Packing | 3-5 Days | Final QC, tagging, boxing |

How Do You Control Quality for Felt Tote Bags During Mass Production?

Receiving a container of defective bags is a buyer's nightmare that costs money and time. How do we catch loose threads and weak handles before they leave the factory floor?

We control quality by inspecting raw materials first. During production, we check stitch tension and handle reinforcement on the line. Final inspection involves checking dimensions, cleaning loose threads, and ensuring the bag stands upright. We also perform load-bearing tests on random units.

Quality control is not just one step at the end. It is a culture. At Coraggio, we start with the material. Felt can sometimes have uneven thickness11. It might be 3mm in one spot and 2mm in another. We check the rolls before we cut. If the felt is too thin, we reject it.

On the production line, my team checks the needle distance. This is the "stitch density12." If the stitches are too far apart, the bag will rip. If they are too close, the needle perforates the felt too much, and it tears like a stamp. We set the machines to the perfect setting.

We also focus on the handles. This is where bags break. I instruct my workers to back-stitch the handles13. This means they sew forward and backward to lock the thread. We do a pull test14. We hang weights on random bags from the production line. We make sure they can hold the weight you asked for.

Visual appearance is also important. Felt bags must stand up straight. If the sewing is crooked, the bag twists. We check the symmetry. We also look for dirty marks. Felt is hard to clean, so we keep the factory floor very clean.

Common Defects We Avoid:

- Pilling15: Using low-quality felt that gets fuzzy.

- Burnt Edges16: Laser cutting temperature too high.

- Uneven Color: Mixing different dye lots in one order.

- Weak Handles: Missing reinforcement stitching.

What Information Do Factories Need for an Accurate Bulk Quote and Lead Time?

Vague inquiries result in slow responses and inaccurate prices from suppliers. Do you know exactly what specs to send to get a fast, firm offer from a manufacturer?

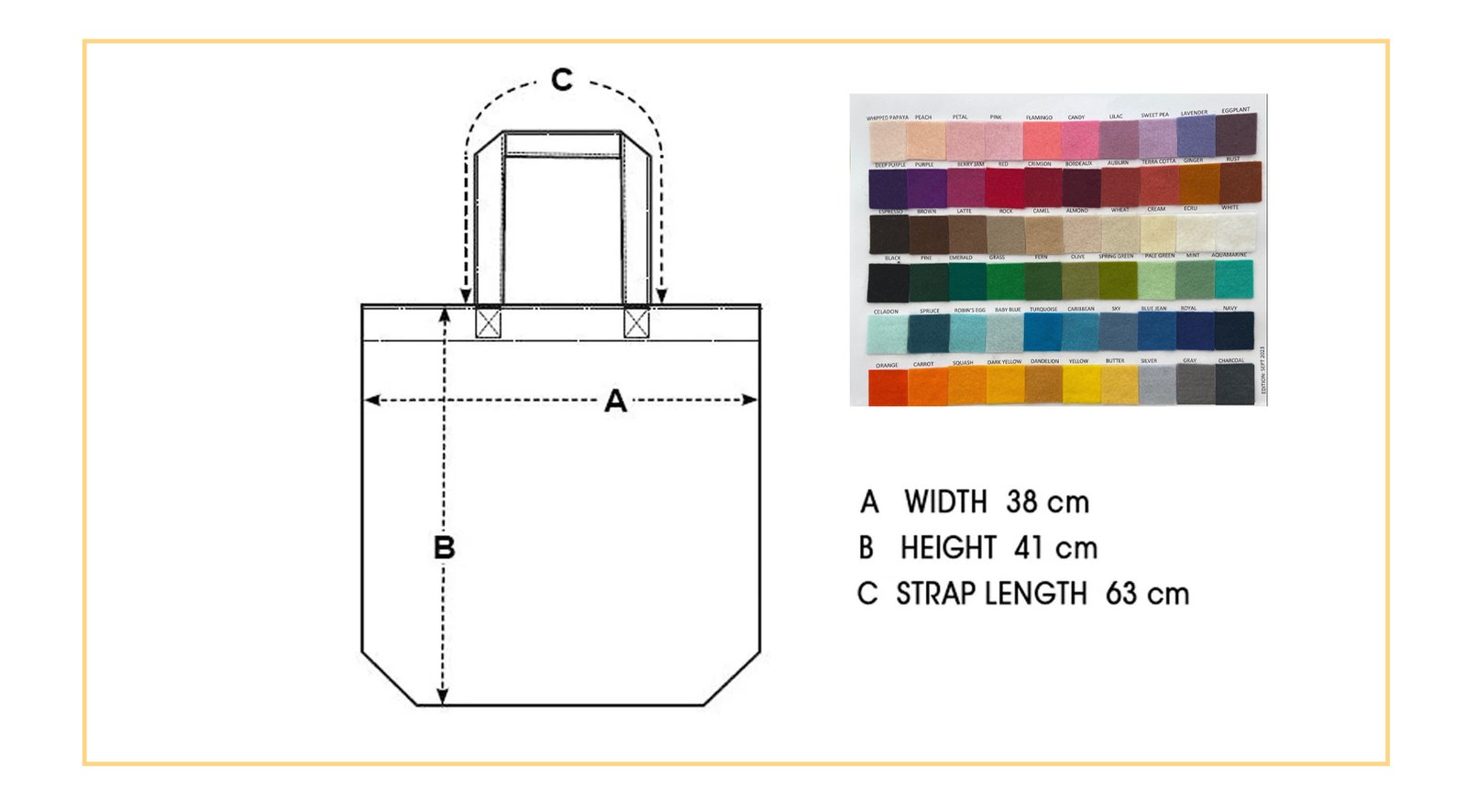

To get an accurate quote, you must provide the bag dimensions (height, width, gusset), felt thickness (e.g., 3mm), quantity, and logo design. You also need to specify the handle material and any special features like pockets or snaps. This allows us to calculate material usage and labor costs.

I get emails every day that say, "How much is a bag?" This is impossible to answer. I want to give you the best price, but I need details. The size changes the price a lot. A big bag uses more material. It also takes longer to sew.

You need to tell me the quantity. A dedicated production run is cheaper than a small trial order. My MOQ is flexible, but the price is better if you order more.

The logo is a big cost factor. A one-color print is cheap. A four-color embroidery is expensive. A leather patch adds material and labor cost. If you send me your logo file, I can calculate the exact cost.

Here is the "Golden List" of information I need:

- Dimensions: Height x Width x Depth (Gusset).

- Material: Felt thickness (Standard is 3mm) and Color.

- Handle: Self-material (felt) or Webbing (nylon/cotton)? What is the length?

- Logo: Size of logo, number of colors, and printing method.

- Extras: Do you need a button? A zipper? An inside pocket?

- Packaging: Do you need individual polybags or bulk packing?

- Quantity: How many pieces do you need?

If you provide this, I can give you a quote in 24 hours. If you do not have a design yet, tell me what you carry in the bag. I can suggest a size and style for you. We have a design team of 10 people. We can help you build the spec sheet.

Conclusion

To successfully make felt tote bags, you must define the thickness and size, approve a physical sample, monitor the cutting and sewing steps, and enforce strict quality control.

Learn why this specific thickness and material balance durability, structure, and cost so your bulk tote bags feel premium, not flimsy. ↩

See how GSM impacts structure, weight, and durability so you can choose a spec that feels robust without being too heavy. ↩

Understand how RPET felt supports sustainability goals while matching the strength and appearance of regular polyester felt. ↩

Avoid costly mistakes by learning when thin felt is acceptable and why it fails for load‑bearing shoppers and totes. ↩

Discover testing and approval methods that prevent shade variation between samples and mass production batches. ↩

Find out how physical swatches help you verify real-life color and texture, avoiding unpleasant surprises on delivery. ↩

Explore the pros and cons of exposed laser-cut edges so you can choose between sleek minimalism and bound finishes. ↩

See how this reinforcement method significantly boosts handle load capacity and reduces breakage in daily use. ↩

See how industrial presses deliver consistent panel sizes at scale, critical for uniform bags in large orders. ↩

Learn how automation boosts accuracy, repeatability, and speed, reducing human error in complex bag orders. ↩

See what inspection methods are used to reject substandard felt before it ruins cutting, sewing, and bag shape. ↩

Discover how proper stitch spacing prevents tearing or perforation, extending the lifespan of your bags. ↩

Find out how back‑stitching locks threads and prevents handles from pulling loose under heavy loads. ↩

See how load-bearing tests simulate real use so you can trust your bags to carry the promised weight safely. ↩

Learn how material selection and processing reduce fuzz and pilling, keeping bags looking new for longer. ↩

Understand optimal laser settings and techniques that prevent discoloration and damage along cut lines. ↩