Are you tired of guessing why one bag costs five times more than another visually similar one? You risk your profit margins1 and brand reputation2 if you choose the wrong supplier for your specific market needs.

A $1 bag3 represents the absolute limit of cost compression4, often using leftover materials and minimal labor. A $5 bag5, however, includes calculated investments in basic quality, durability, and aesthetics, making it suitable for retail shelves rather than just one-time promotional events.

Many buyers think factory pricing is a mystery, but it is actually simple math. I will show you exactly where every cent goes in my factory to help you make the right choice.

How Do Materials and Craftsmanship Dictate the Price Tag?

Cheap bags tear easily, and your customers will get angry if the bottom falls out. This usually happens because the fabric is too thin or the stitching is too weak.

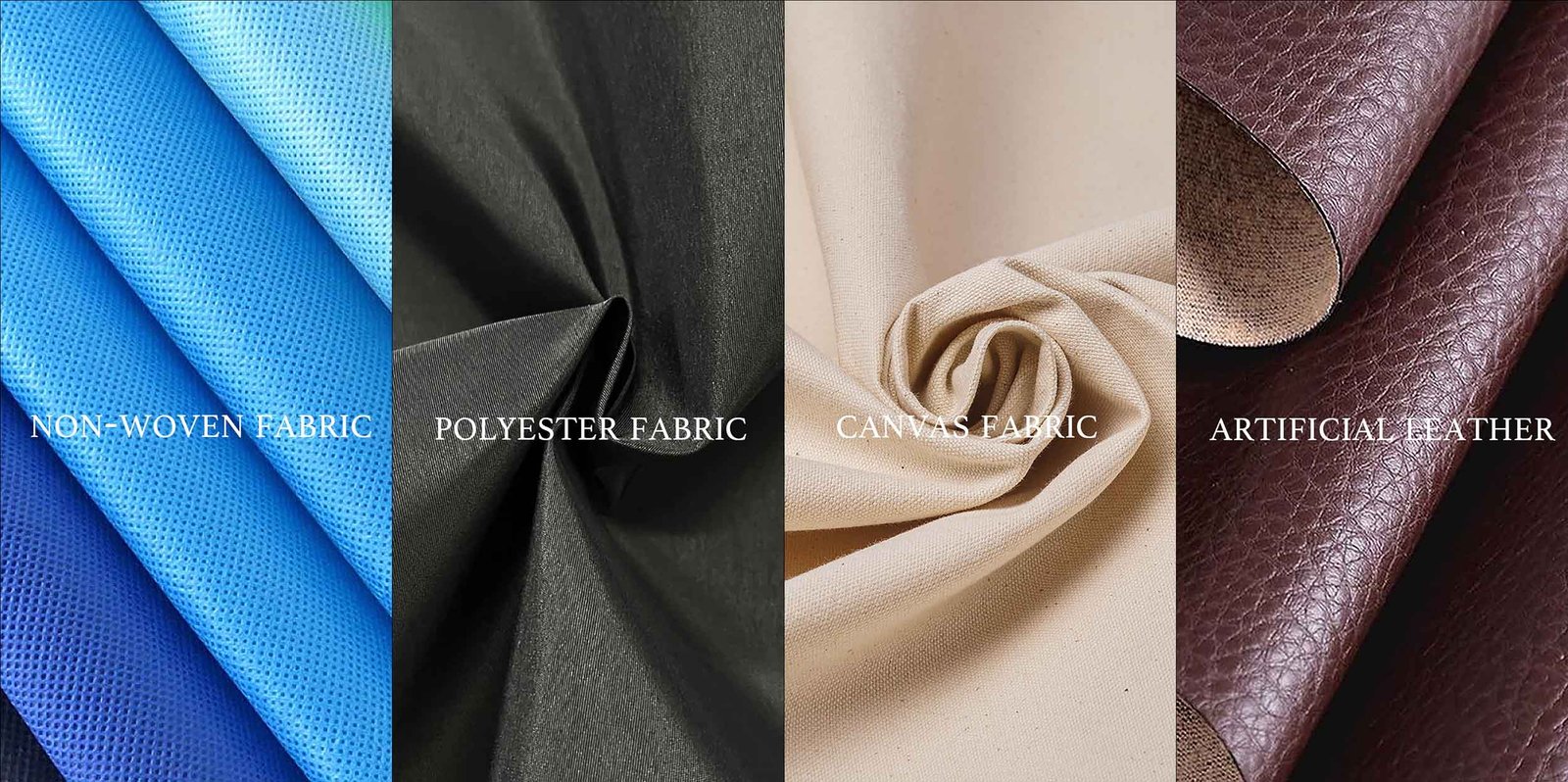

$1 bag3s often use non-woven fabric or thin 190T polyester6 with single stitching to save money. $5 bag5s upgrade to 600D polyester7, canvas, or faux leather with reinforced stitching, ensuring the bag holds weight without breaking.

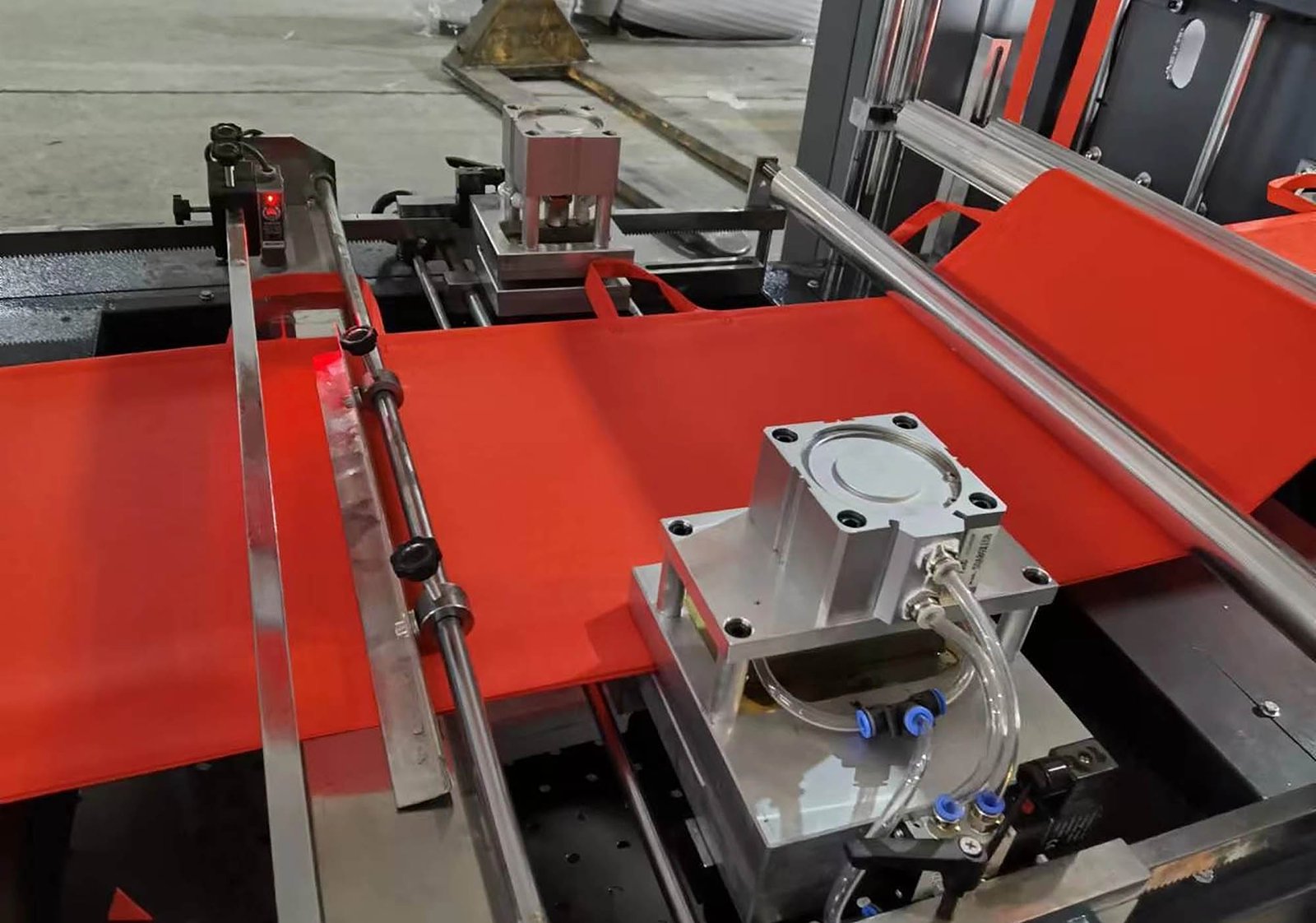

In my 15 years running Coraggio, I have seen many buyers make mistakes with materials. When we make a $1 bag3, we are often buying "stock fabric8." This means we buy whatever is cheapest on the market that day. Sometimes the color varies slightly between batches. The material is often non-woven polypropylene or very thin polyester. It feels like paper. We use a single line of stitching. We do not fold the edges over for strength. We just sew it once and move on. This keeps the cost very low.

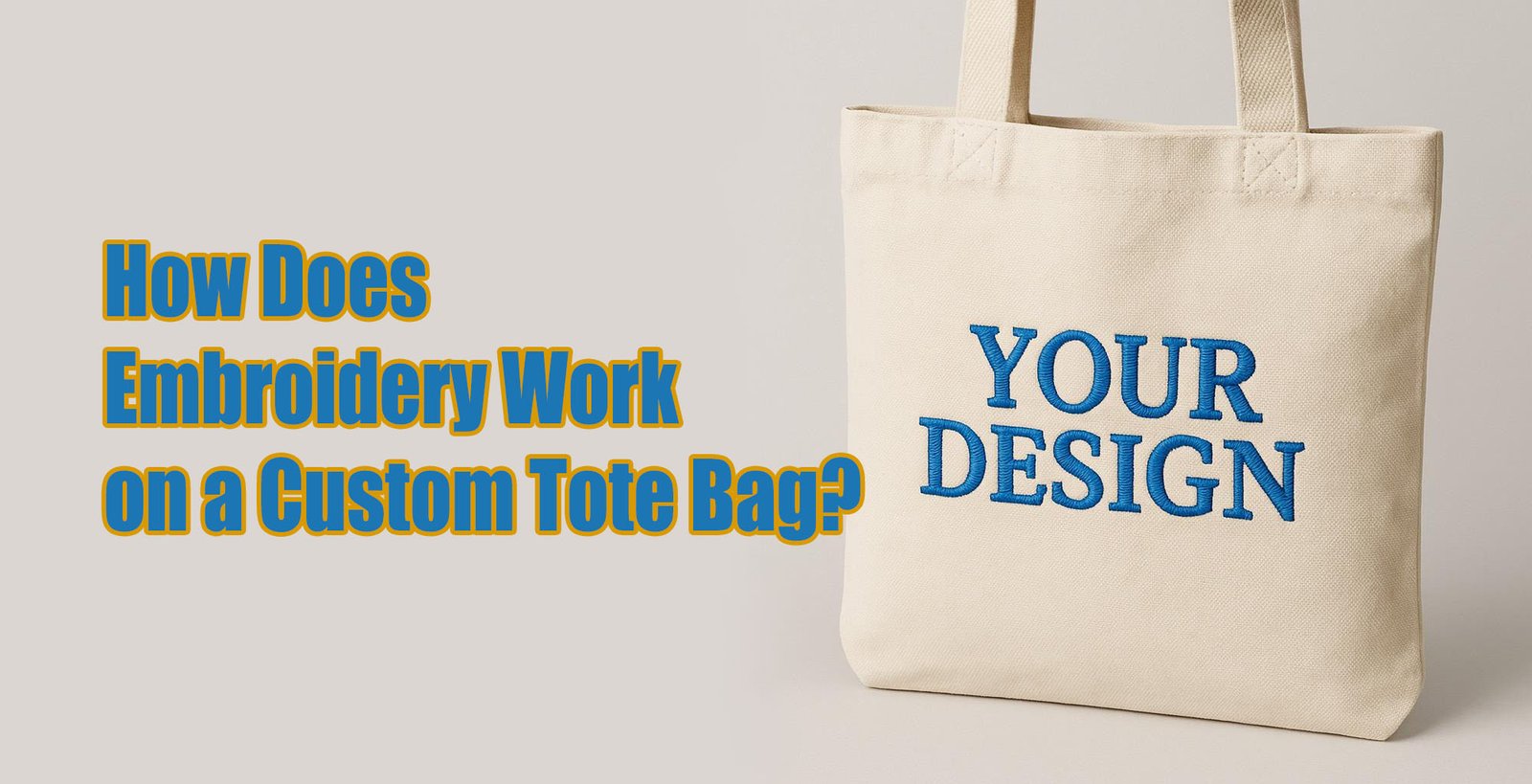

However, for a $5 bag5, the approach changes completely. We order fresh rolls of fabric specifically for your order. We use materials like 600D Oxford cloth or heavy cotton canvas. These materials have a PVC or PU coating on the back. This coating makes the bag waterproof and gives it a strong shape. The craftsmanship is also different. My workers will use "back-stitching9" at the stress points. This means they sew over the handle attachment area three or four times. We also use binding tape on the inside seams so the fabric does not fray.

| Feature | $1 Bag Construction | $5 Bag Construction |

|---|---|---|

| Main Material | Non-woven (80gsm)10 or 190T Polyester | 600D Polyester, Canvas, or PU Leather |

| Stitching | Single stitch, wide spacing | Double stitch, tight spacing |

| Reinforcement | None | Cross-stitching (X-box) on handles |

| Inner Seams | Raw edges (might fray) | Bound with piping tape |

| Hardware | Plastic or thin wire | Zinc alloy or heavy plastic |

Does Low Cost Mean Zero Design and Quality Control?

You hate defects because they ruin your delivery schedule and cost you money. But you also want the lowest price possible, which forces the factory to cut corners.

$1 bag3s have almost no design cost and very loose inspections to speed up production. $5 bag5s include basic utility design improvements11 and mandatory quality checks to reduce defect rates significantly.

Let's be honest about "design." For a $1 bag3, there is no real design work. We take a standard template that we have used for ten years. We cut the fabric and sew it. If the logo is slightly crooked, we might still ship it. If there are loose threads, we do not pay a worker to trim them. Time is money. To sell a bag for $1, I cannot pay a worker to spend 30 seconds cleaning it. The quality control12 standard is "Is it a bag?" If yes, it goes in the box.

For a $5 bag5, my design team of 10 people gets involved. We look at the usage. Does it need an inner pocket? Does the zipper pull need to be larger for easier gripping? We make these small adjustments. Then comes the production line. In my factory, we have 120 workers. For higher-priced orders, we assign specific QC (Quality Control) staff to the line. They check every single bag. They trim all the loose threads. They test the zipper three times. They check for color matching. If a bag has a scratch, it is rejected. You are paying for this labor. You are paying for the assurance that when your customer Michael Thorne opens the box in Canada, he sees a clean, perfect product.

Is the Goal "Just Usable" or "Reliable for the Market"?

A broken bag is trash, and selling trash hurts your brand image permanently. You need to know if the product will last one day or one year.

The $1 standard is "barely usable" for a short time, like a trade show. The $5 standard aims for stability, ensuring the product functions correctly for the end consumer over a longer period.

This is the most important part for your business model. You must understand the "lifespan" of the product. A $1 bag3 is a "cost compression4" product. We squeeze every penny out of it. It is designed to carry a brochure and a water bottle at an exhibition. After the event, the user might throw it away. If you are a buyer for a company giving away free gifts, this is perfect. You do not need durability. You need volume.

But if you are a buyer for a supermarket or a fashion brand, a $1 bag3 is dangerous. A $5 bag5 represents a leap into the "consumer goods13" market. It balances cost with durability. We build these bags to last for months or years. We use critical thinking during production. We ask, "If I put 10kg of groceries in this, will the handle rip?" For the $5 bag5, the answer must be "No." We test the load-bearing capacity14. We test the color fastness so it does not stain the user's clothes. This price point allows us to use materials that look good and feel good. It is not just about holding things; it is about the user experience.

Which Price Point Fits Your Business Model Best?

Choosing the wrong price point can destroy your profit margins1 or leave you with unsellable stock. You need to match the manufacturing cost to your specific sales channel.

Low-priced bags are for high-volume, low-margin promotional activities15. Higher-priced bags are for retail environments16 where brand reputation2 and repeat customers are the priority.

I deal with buyers from Europe and North America every day. I see successful strategies and failed ones. The buyers who fail are the ones who want $5 quality for $1. It is impossible. If you push a factory to give you a $5 look for $1, we will have to cheat on materials. We will use thinner glue. We will use recycled plastic that smells bad. Eventually, your customers will complain.

If you are Michael Thorne and you are buying for a promotional event, buy the $1 bag3. It does the job. But if you are rebranding these bags to sell in a store in Canada, you must spend $5. The $5 bag5 allows you to mark it up to $15 or $20 retail. The customer feels the quality. They see the nice metal zipper. They feel the thick canvas. They are happy to pay. You build a reputation for quality. In my factory, we support both models. We have production lines for quick, cheap items, and we have lines for detailed, high-quality items. The key is transparency. I will tell you exactly what you are getting. Do not try to trick the manufacturing cost. It always comes back to hurt the quality.

Conclusion

$1 bag3s maximize quantity for one-time use, while $5 bag5s invest in materials and labor for long-term retail value. Choose the one that matches your final customer's expectations.

Learn how selecting the right product can significantly affect your business's profit margins. ↩

Explore the significance of brand reputation and how it relates to product quality. ↩

Explore the features of $1 bags to understand their limitations and appropriate use cases. ↩

Learn about cost compression and its impact on product quality and pricing strategies. ↩

Discover the benefits of $5 bags and how they can enhance your brand's reputation. ↩

Understanding 190T polyester helps you assess its suitability for cost-effective bag production, ensuring you make informed purchasing decisions. ↩

Discover why 600D polyester is preferred for durable bags, offering strength and water resistance, ideal for retail and long-term use. ↩

Understanding stock fabric helps you grasp why $1 bags vary in quality and color, impacting your choice for promotional or retail purposes. ↩

Understanding back-stitching helps ensure bag durability, crucial for maintaining quality and customer satisfaction in retail environments. ↩

Understanding non-woven fabric helps you assess its cost-effectiveness and suitability for products like $1 bags, ensuring informed purchasing decisions. ↩

Learn about design enhancements that can elevate the functionality and appeal of bags. ↩

Find out how quality control processes can prevent defects and ensure product reliability. ↩

Understanding consumer goods helps you choose products that meet long-term customer expectations and enhance brand reputation in retail environments. ↩

Discover the importance of load-bearing capacity in ensuring bag reliability and customer satisfaction. ↩

Understand how promotional strategies dictate the choice between low-cost and high-quality bags. ↩

Explore the unique challenges and strategies for successfully selling bags in retail settings. ↩