Blurry logos and faded colors1 can instantly ruin your brand's reputation. You cannot afford to waste money on bags that look cheap. Choosing the right fabric fixes this immediately.

For most B2B bag projects, polyester (including RPET)2 is the best choice for digital printing. It offers sharp, vibrant images and long-lasting color, especially with sublimation3. Cotton canvas works but often looks less vibrant. Always choose smooth, tightly woven fabrics4 for the clearest results.

I have seen many buyers make mistakes with fabric selection. They pick a material that feels good but prints poorly. This guide helps you avoid those costly errors. Read on to learn exactly which materials ensure your custom bags look professional and sell fast.

What Is Digital Printing on Bag Fabrics?

Traditional printing methods limit your design options significantly. You want complex patterns, but factories say "no." Digital printing solves this by allowing unlimited colors and details.

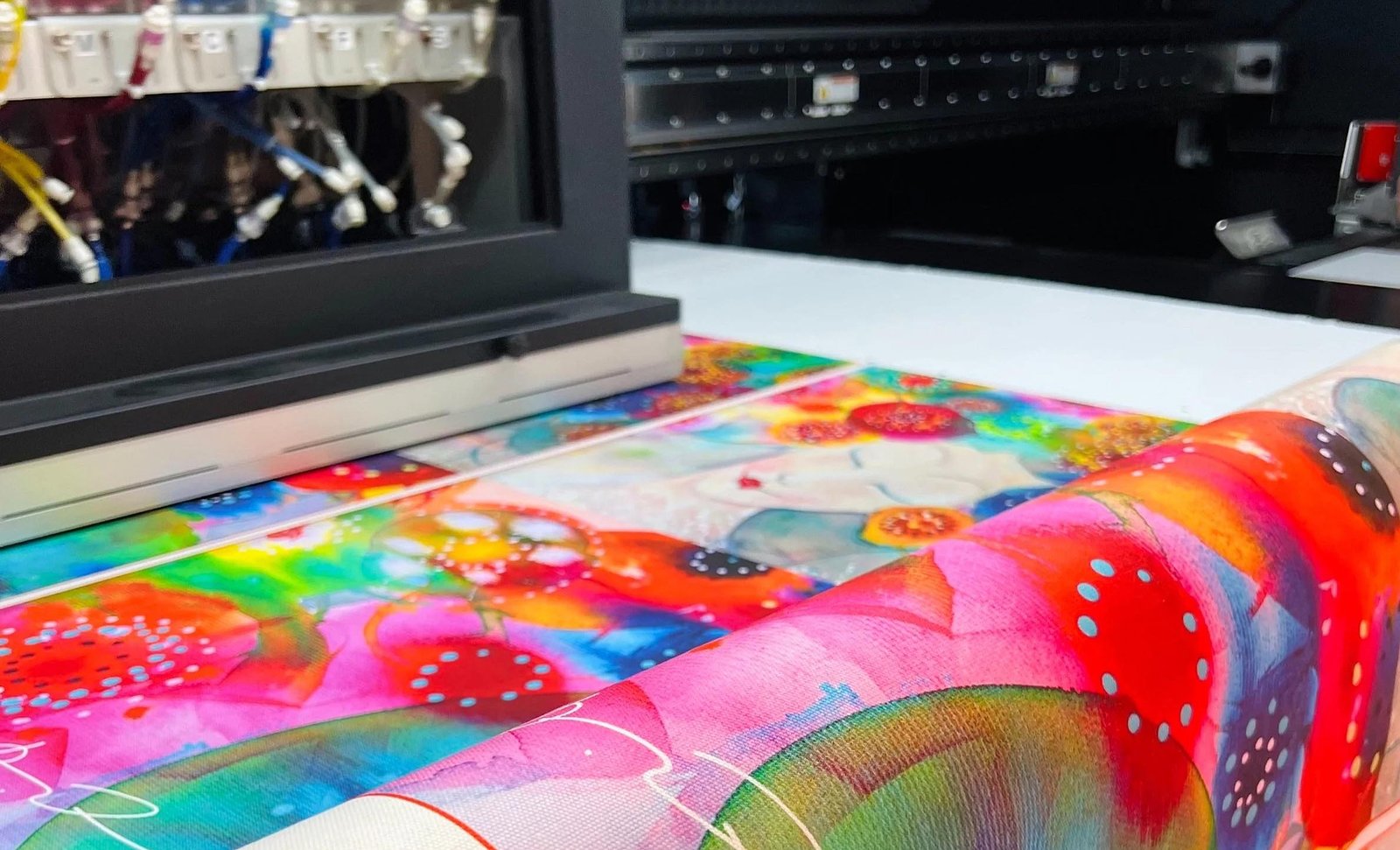

Digital printing on bag fabrics is a method where artwork is printed directly from a computer file onto material. Unlike screen printing, it does not require screens. It allows for photo-realistic images, gradients, and complex patterns5 on materials like polyester, canvas, and nylon without high setup costs6.

In my 15 years at Coraggio, I have seen technology change how we make bags. Digital printing works like your office inkjet printer but on a huge scale. The machine sprays tiny drops of ink onto the fabric. This is different from screen printing. Screen printing needs a physical screen for every color. That gets expensive and slow. Digital printing skips that step. You send a file, and we print it. This is great for complex designs. If your client wants a photo of a landscape on a tote bag, digital printing is the only way. It captures shadows and gradients perfectly.

It also helps with speed. We do not need days to make screens. We can start production faster. This is vital when you have a tight deadline for a trade show. However, the ink must bond with the fabric. Not every fabric accepts ink the same way. The chemistry must match. For example, some inks sit on top of the fabric, while others soak in. If you choose the wrong combination, the ink might bleed or rub off. This is why understanding the process helps you make better buying decisions. You save money on setup fees, but you must apply that budget to choosing the right base material.

| Feature | Screen Printing | Digital Printing |

|---|---|---|

| Setup Cost | High (per color) | Low (minimal setup) |

| Color Limit | Limited | Unlimited |

| Detail Level | Medium | High (Photo-realistic) |

| Speed | Slow setup, fast run | Fast setup, medium run |

| Best For | Simple Logos | Complex Art |

Which Fabrics Deliver the Sharpest Colors and Details for Bag Printing?

Dull colors make your products look old before they sell. Your customers ignore bags that lack visual pop. The right fabric ensures your design looks crisp and expensive.

Synthetic fabrics7 generally deliver the sharpest colors and details. Tightly woven polyester and smooth nylon allow ink to sit precisely on the surface. Natural fibers like cotton absorb more ink, which can soften the image. For high-definition logos and photos8, smooth synthetics are the superior choice.

I always tell Mark, my client from Canada, to look at the surface of the fabric. Imagine drawing on a piece of paper versus drawing on a paper towel. The paper is smooth, so the lines are sharp. The paper towel absorbs ink, so lines bleed. Fabric works the same way. Polyester is the "paper" in this example. It is synthetic and usually has a smooth surface. The ink stays where it lands. This results in very sharp lines and bright colors. 600D Polyester9 is a standard we use often. It holds detail very well. RPET (recycled polyester)10 works just as well. This is good for your eco-friendly marketing11.

Nylon can also be good, but it is tricky. It is very smooth, sometimes too smooth. The ink might run if the coating is wrong. You must test it. Cotton is different. It is natural and absorbent. When we spray ink on cotton, the fiber drinks it. This creates a softer, more vintage look. The colors are less punchy. If you want a neon bright logo, cotton is the wrong choice. If you want a natural, organic look, cotton is fine. But for pure sharpness and detail, synthetics win every time. You get better value because the product looks higher quality on the shelf.

| Fabric Type | Sharpness Rating | Color Vibrancy | Best Use Case |

|---|---|---|---|

| Polyester | High | High | Detailed photos, bright logos |

| RPET | High | High | Eco-friendly brands, complex art |

| Nylon | Medium/High | Medium | Sport bags, simple graphics |

| Cotton | Low/Medium | Low (Matte) | Vintage styles, simple text |

Which Bag Fabrics Work Best for Sublimation Digital Printing?

Peeling prints result in angry customers and returns. You lose profit when logos fade after one wash. Sublimation prevents this, but only if you pick the correct material.

Sublimation digital printing works best on fabrics with a high polyester content. The process uses heat to turn ink into gas, which bonds permanently with synthetic fibers. 100% polyester or blends with at least 65% polyester produce the most vibrant, durable, and wash-resistant results12.

Sublimation is a favorite technique in our factory. It is magic for durability. We print the design on paper first. Then we press it onto the fabric with heat. The heat makes the fabric pores open. The ink turns into gas and goes inside the fiber. When it cools, the pores close. The ink is now part of the bag. It is not just sitting on top. This means it will never crack or peel. You can scratch it, wash it, or leave it in the sun. The design stays.

This only works with polymers. Polyester is a polymer. Cotton is not. If you try this on cotton, the ink washes right out. I had a client insist on sublimating cotton canvas once. I showed him a sample. It looked good for one day. After he washed it, the image was gone. He listened to me after that. If you must use a cotton feel, we can use a poly-cotton blend. But the polyester part must be at least 65%. If the polyester content is low, the image will look faded. For the best result, stick to 100% polyester or RPET. This ensures your customer gets a bag that lasts for years. This builds trust in your brand quality.

- Polyester (100%): Perfect result. Brightest colors.

- Polyester Blend (65%+)13: Good result. Slightly "distressed" look.

- Cotton (100%): Impossible. The image will wash away.

- Nylon: Difficult. Nylon melts at high heat, so sublimation3 is risky.

How Do Fabric Texture and Coating Affect Digital Print Results on Bags?

A rough texture can break up your beautiful design. You might see gaps in your logo where the ink missed. Understanding texture ensures your brand image remains solid and professional.

Fabric texture and coating14 are critical for print clarity. Rough textures create gaps in the print, making fine text unreadable. Smooth, coated fabrics provide a flat canvas for the ink. A proper coating prevents ink absorption, ensuring colors remain bold rather than soaking into the weave.

Texture is the physical feel of the bag. Think about a heavy canvas tote. It has a bumpy surface. If you print a small letter "A" on a bump, half the letter might disappear into a valley between threads. This is bad for detailed instructions or QR codes. For rough fabrics like canvas, we need to use more ink. This can make the image look dark or muddy. I recommend using a "tight weave15" for any complex art. This means the threads are packed closely together. It creates a flatter surface.

Coating is a chemical layer we add. It acts like a primer on a wall. Without primer, the wall sucks up the paint. Without coating, the fabric sucks up the ink. For materials like Nylon or Oxford cloth, the coating determines success. If the coating is not compatible with the ink, the ink will not dry or it will scratch off. We often have to treat the fabric before printing. This is called "pre-treatment16." It helps the ink stick and stay bright. If you skip this to save money, your black colors will look gray. Always ask us if the fabric needs a coating for your specific design.

| Texture Type | Print Challenge | Solution |

|---|---|---|

| Rough Canvas | Ink falls into gaps | Use bold, simple designs |

| Smooth Oxford | Ink might slide off | Use proper coating |

| Tight Weave | None (Ideal) | Good for all designs |

| Loose Weave | Low resolution | Avoid fine text |

What Should B2B Buyers Ask a Bag Supplier Before Choosing a Print Fabric?

Miscommunication leads to containers full of wrong products. You cannot risk a shipment arriving with blurry prints. Asking the right questions upfront protects your investment and timeline.

Before finalizing an order, ask your supplier for digital print samples on your specific fabric choice. Inquire about the ink type, wash fastness rating17, and color matching capabilities (Pantone)18. Confirm if the fabric requires pre-treatment16 and if the factory has experience printing on that specific material.

You need to protect your business. Do not just say "I want digital printing." You must be specific. In my experience dealing with buyers from North America, the successful ones ask for physical proofs. A digital mockup on a screen is not enough. Screens have light behind them. Fabric does not. The colors will look different. You must see the ink on the actual material. This is the only way to check clarity.

Ask about the "hand feel" after printing. Some digital prints make the fabric feel stiff. This might be okay for a cooler bag, but bad for a cosmetic bag or a soft backpack. Ask about UV resistance. If you are selling beach bags, the sun will fade the ink. We can use UV-resistant ink19, but you must ask for it. Also, ask about the price difference between fabric types. Polyester is usually cheaper to print than cotton because cotton needs that extra pre-treatment16 step I mentioned earlier. Finally, ask about "color fastness20." This is a test of how well the color stays. You want a rating of 4 or higher.

Key Questions Checklist:

- Can I see a physical sample of my design on this specific fabric?

- Does this fabric require pre-treatment16, and is that included in the price?

- What is the wash fastness rating17 for this ink on this material?

- Will the printing change the stiffness (hand feel) of the bag?

- Can you match my Pantone colors exactly on this texture?

Conclusion

To get the best results, choose smooth polyester or RPET for your bags. Always test the fabric with your supplier to ensure sharp details and vibrant, lasting colors.

Understanding how poor print quality damages trust helps you justify investing in better fabrics and printing methods for your bags. ↩

Learn how polyester and RPET deliver sharper, longer-lasting prints while supporting both cost efficiency and sustainability goals. ↩

See why sublimation creates crack-free, wash-resistant prints so your branded bags look new after repeated use and washing. ↩

Discover how fabric structure directly impacts sharpness, color vibrancy, and the overall professional look of your printed bags. ↩

Find techniques that let you print intricate artwork and photography on bags without losing detail or color depth. ↩

Compare real cost structures so you can choose the most economical print method for small runs and complex designs. ↩

Understand the science of ink interaction with synthetics so you can choose fabrics that maximize print clarity and color. ↩

Learn best practices to ensure your logo and imagery stay razor-sharp on finished bags, even at close viewing distance. ↩

See real print examples on 600D polyester to verify sharpness, durability, and feel before committing to large orders. ↩

Learn how RPET supports eco-branding while still delivering vivid, durable prints your customers will actually notice. ↩

Explore how sustainable bag materials can strengthen your brand story and appeal to environmentally conscious buyers. ↩

Avoid customer complaints by choosing methods that keep colors intact after repeated washing and heavy use. ↩

See how high-poly blends balance durability, vibrancy, and hand feel if you don’t want fully synthetic fabrics. ↩

Learn how to evaluate fabric surfaces and coatings so your detailed artwork prints cleanly instead of looking patchy. ↩

Understand how thread density impacts resolution so you can avoid low-quality, pixelated-looking prints. ↩

See when pre-treatment is worth paying for to prevent ink bleed, fading, and poor color saturation on your bags. ↩

Learn the standards for wash fastness so you can specify requirements that keep your prints looking fresh longer. ↩

Ensure your brand colors remain consistent across fabric types by understanding Pantone matching limitations and solutions. ↩

Protect outdoor and beach bags from sun fade by learning which UV inks actually extend print life in real conditions. ↩

Know how color fastness is measured so you can demand verifiable durability from your bag suppliers before ordering. ↩