Sourcing bags implies a tough choice between premium feel and budget control. Choosing the wrong material hurts your margins. Here is how I decide between leather and PU for bulk orders1.

snippet paragraph: For most B2B wholesale orders, PU (Polyurethane) is better due to lower costs, consistent quality, and faster production2 times. However, Genuine Leather is superior for high-end markets3 requiring durability and luxury pricing. Your choice depends on your target demographic4, budget per unit, and specific durability requirements.

Many buyers ask me this question. I have seen clients lose money by picking the wrong material for their market. I want to help you avoid that mistake. Let us look at the details.

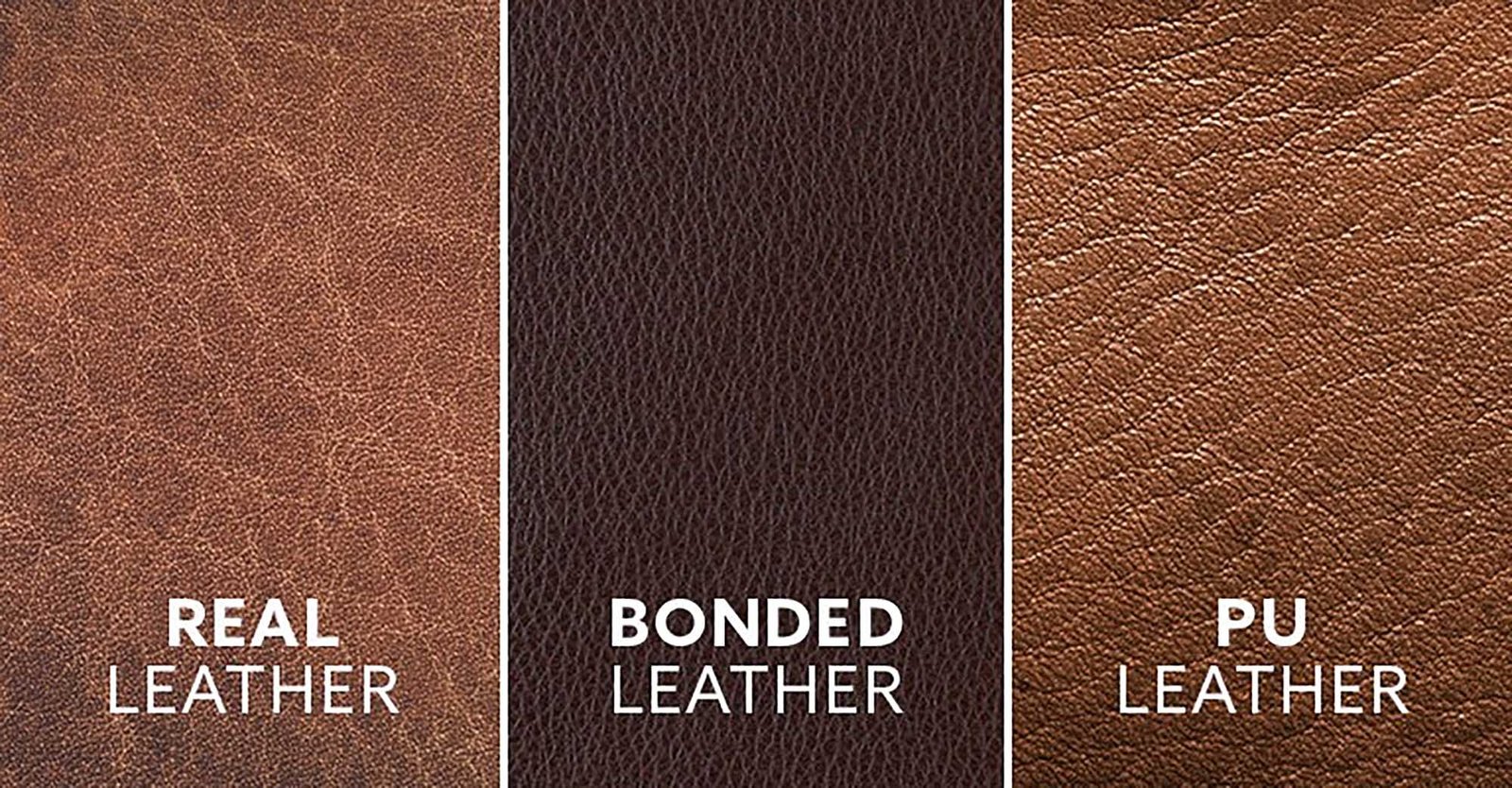

What’s the Key Difference Between Leather and PU for Bag Manufacturing?

You cannot always tell them apart just by looking. But the origin and structure are totally different. This affects how we make your bags on the production line5.

Real leather comes from animal hides, meaning every piece is unique and natural. PU is a synthetic plastic material made to look like leather. Leather breathes and ages; PU is uniform, water-resistant6, but does not age the same way or last as long.

I have spent 15 years in this industry, and I see buyers confuse these materials often. The main difference lies in the source. Genuine leather is a natural product. It comes from cows, sheep, or pigs. Because it is natural, it has imperfections. You might see scars or grain variations. This makes cutting difficult. We cannot use the whole hide. We have to cut around the bad parts. This increases waste.

PU, or Polyurethane, is man-made. It is a polymer applied to a base fabric. It comes in rolls, just like fabric. This is a huge advantage for manufacturing. We can cut it automatically with machines. There are no scars or holes to avoid. The grain is stamped on, so it looks perfect every time. For a factory like Coraggio, PU allows for faster production2. We can predict the yield exactly. With leather, the yield varies with every batch. If you need 100% identical bags, PU is the safer choice.

| Feature | Genuine Leather | PU (Polyurethane) |

|---|---|---|

| Origin | Animal Hide (Natural) | Plastic Polymer (Synthetic) |

| Consistency | Varies (Natural marks) | Uniform (Perfect rolls) |

| Breathability | High (Pores) | Low (Plastic coating) |

| Water Resistance | Low (Absorbs water) | High (Repels water) |

Which Material Is More Durable for Wholesale Orders: Leather or PU?

Customers hate it when bags peel or crack after a few months. Durability builds your brand reputation. You need to know which one lasts longer in real use.

Genuine leather generally lasts much longer, often 10 to 20 years, as it resists tearing and puncture. High-quality PU lasts 2 to 5 years but eventually cracks due to hydrolysis7. For short-term fashion items, PU is fine; for legacy products8, use leather.

Durability is not just about strength. It is about how the material ages. Leather is very strong. The fibers are interwoven naturally. It is hard to tear. Over time, leather gets softer. It develops a "patina." This means it looks better as it gets older. If you scratch it, you can often buff it out. This makes it great for travel bags or heavy-use items.

PU has a different problem. It does not rot, but it suffers from hydrolysis7. This happens when moisture in the air breaks down the chemical bonds. After a few years, the surface will peel off. You have likely seen this on cheap jackets or bags. The "skin" flakes off. High-end PU lasts longer, but it will not last forever. Also, PU is easier to puncture. Once it tears, you cannot fix it. If your customers expect a bag to last a decade, you must choose leather. If they change bags every season, PU is durable enough.

How Do Leather and PU Compare on Cost and MOQ for B2B Sourcing?

Price is your main concern when importing containers. You need to calculate the landed cost9 accurately. Material choice changes your profit margin significantly.

Leather is expensive, costing 3 to 5 times more than PU per yard. It also often requires higher MOQs due to hide purchasing. PU is cheap and available in stock rolls, allowing for lower MOQs and better margins for mass-market retail.

This is where the business decision happens. Leather is expensive for two reasons. First, the raw material cost is high. Second, the labor cost is high. We need skilled workers to cut leather. They must look at the hide and decide where to place the pattern to avoid defects. This takes time. Also, we waste about 20% to 30% of the material. You pay for that waste.

PU is much cheaper. It costs a fraction of leather. We can stack layers of PU and cut them all at once. The waste is very low. This makes the unit price much lower. Also, consider the Minimum Order Quantity (MOQ)10. Leather suppliers often sell by the batch. If you want a custom color, you might need to buy 1,000 sq ft minimum. PU suppliers keep stock colors. We can buy small amounts. This means Coraggio can offer you lower MOQs for PU bags. This lowers your inventory risk.

| Factor | Genuine Leather | PU Leather |

|---|---|---|

| Raw Material Cost | High ($3.00 - $6.00+ / sq ft) | Low ($2.00 - $5.00 / yard) |

| Labor Cost | High (Manual cutting) | Low (Automated cutting) |

| Material Waste | High (Irregular shapes) | Low (Rectangular rolls) |

| MOQ Flexibility | Low (Batch orders) | High (Stock available) |

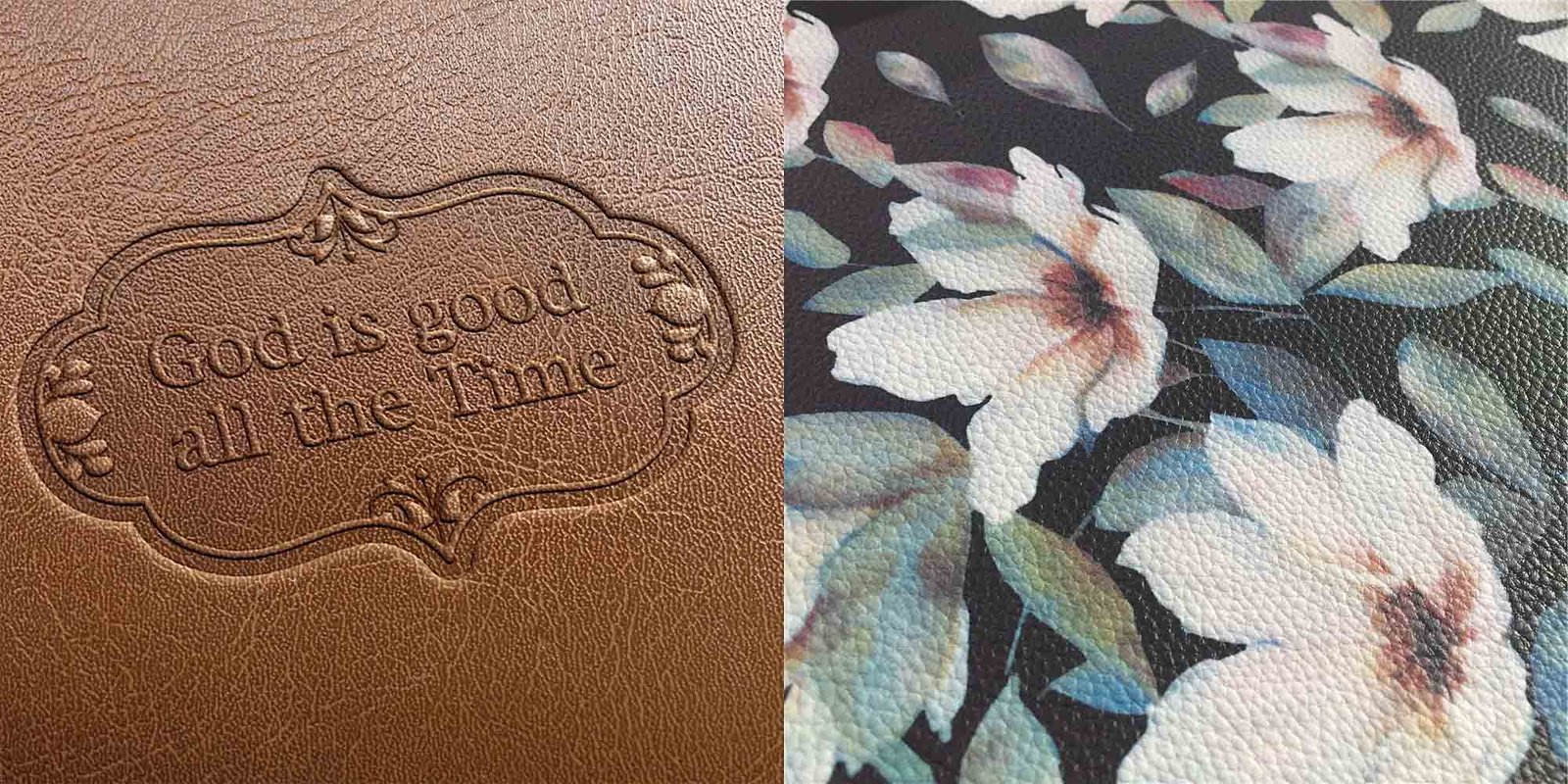

Which Is Better for Branding: Printing, Embossing, and Logo Options?

You want your logo to look sharp and stay on the bag. The material surface changes how we apply your brand identity and how long it stays visible.

Leather is excellent for embossing and debossing11 because the natural fibers hold the shape deeply. PU is better for screen printing12 and digital printing because the surface is smooth and uniform. Foil stamping works well on both, but leather holds it longer.

Branding makes your product unique. I always tell clients to think about the logo method before choosing the material. If you want a subtle, high-class look, embossing is best. We use a hot metal die to press your logo into the material. Leather takes this very well. The heat changes the color slightly, making it look natural. The depth is permanent.

PU can be embossed, but it is tricky. If we press too hard, we might melt the plastic. If we do not press hard enough, the logo "bounces back" and disappears after a few weeks. For PU, I suggest metal plates or printing. Screen printing looks very sharp on PU because the surface is flat. On leather, the grain breaks up the ink. If you have a complex, colorful logo, PU is the better canvas. If you want a simple, classic logo, leather is the winner.

Which Should You Source for Your Market: Leather or PU?

Knowing the material is useless if you do not know your customer. You must match the bag spec to the retail price point and your brand image.

Choose leather if your retail price is over $100 and you target professionals or luxury buyers. Choose PU if you sell fast fashion13, gift items, or products under $50. PU allows for trendy colors, while leather sells on "tradition" and "quality."

I see this mistake often. A buyer wants a cheap bag but asks for leather. Or they want a luxury bag but use PU. You must align with your market. If you sell to supermarkets or corporate gift companies, PU is the right choice. These customers want a good look at a low price. They want consistency. They want 10,000 bags that look exactly the same. PU delivers this.

If you sell to boutiques or high-end department stores, you should use leather. These customers pay for the "story." They want the smell and the feel of real skin. They accept that it is heavy. They accept the price. My insight is simple: PU is for volume and speed. Leather is for margin and prestige. Before you ask for a quote, look at your competitors. What are they selling? If you use PU, we can make the bag look expensive with good hardware and lining. But we cannot fake the smell of leather.

What Fabric Specs Matter for Bags?

Maybe you want to mix materials or use a lining. You cannot ignore the technical specs of the fabric supporting the leather or PU structure.

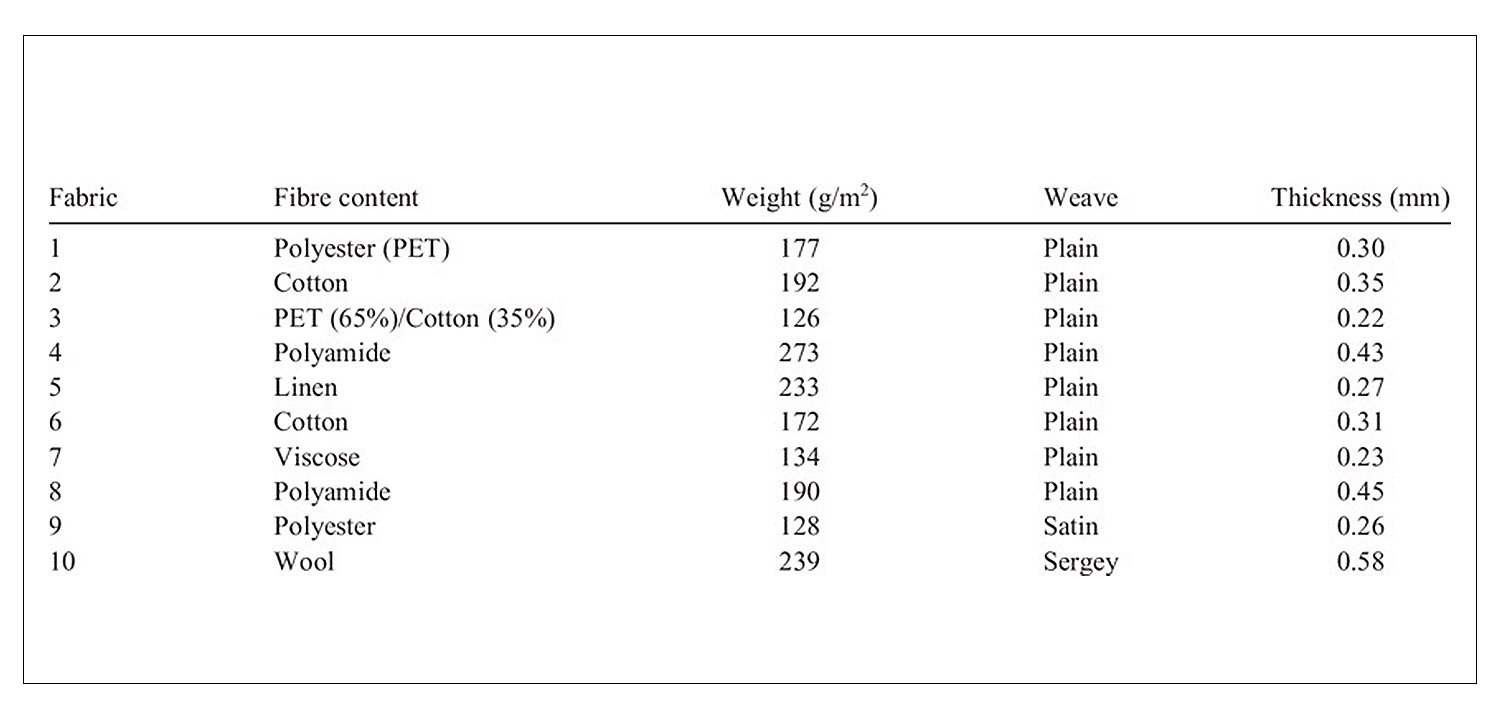

You must look at Denier (thickness), backing material, and coating. For PU, the backing fabric determines strength. For leather, the thickness (split vs. top grain) matters. Always ask for the weight in GSM and the tear strength test results.

When you buy PU, you are not just buying the plastic top layer. You are buying the backing too. This is crucial. Cheap PU uses a weak, non-woven backing. It tears easily. Good PU uses a woven cotton or polyester backing. It is strong. You need to specify the thickness. Usually, 0.8mm to 1.2mm is good for bags. If it is too thin, the bag looks floppy. If it is too thick, it is hard to sew.

For leather, we talk about "weight" or thickness in millimeters. Full-grain is the top layer. It is the strongest. Split leather is the bottom layer. We coat it to look like the top layer. It is cheaper but weaker. You also need to think about the lining. A strong outer material needs a strong lining, like 210D or 420D polyester. If the lining rips, the customer thinks the whole bag is bad. We must balance the outer shell with the inner support.

How Do You Control Quality Risks?

Bad quality destroys your business in Canada. You cannot fix defective bags once they arrive at your warehouse. You need strict control at the factory.

For leather, check for scars, insect bites, and color variation between batches. For PU, check for peeling, chemical smells, and thickness consistency. I always recommend a pre-shipment inspection14 to check stitching strength and material integrity before the container leaves China.

Quality control is different for these two materials. With leather, the risk is natural defects. We have to inspect every single hide. We look for holes or thin spots. Color matching is also hard. One batch might be slightly darker than the next. You must accept a "tolerance" for color. If you are very strict about color, leather is a nightmare.

With PU, the risk is chemical. Sometimes, the factory cures the material too fast. It smells like strong chemicals. Or the layers delaminate (separate). We check this by doing a "rub test" and a "smell test." At Coraggio, we have 10 people on our design and QC team. We inspect the material when it arrives, not just the finished bag. This is key. We catch the bad material before we cut it. This saves time and money. I always advise you to sign off on a "Gold Sample" so we have a standard to match.

What Are the MOQ, Lead Time, and Cost Drivers for Recycled Fabric Bags?

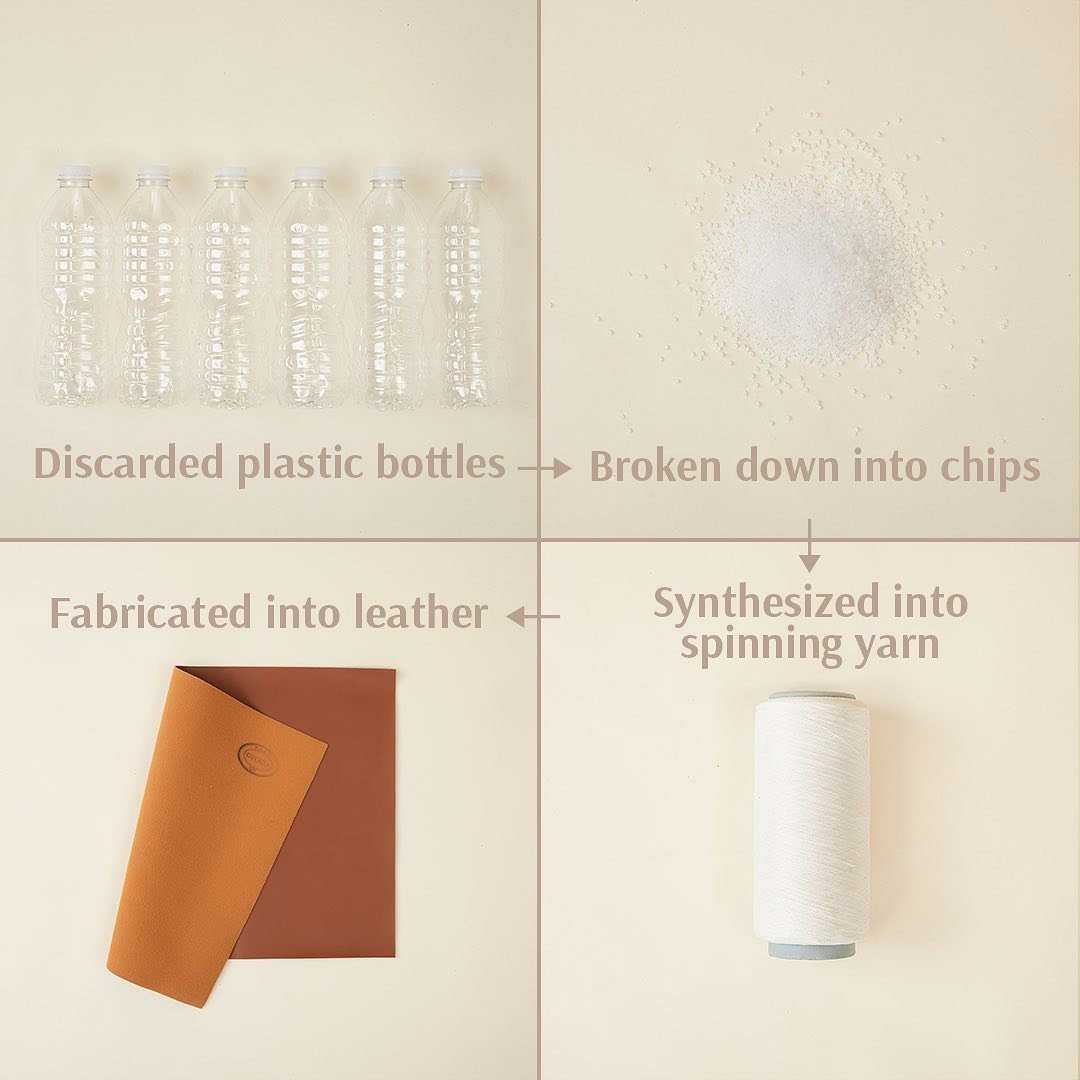

Sustainability is a big trend now. You might want to switch from standard PU to recycled options like RPET or recycled leather to appeal to eco-conscious buyers.

Recycled materials (like RPET or recycled PU) usually cost 15-20% more than standard PU. The MOQ is often higher (e.g., 3,000 yards) because factories do not stock it. Lead times are longer because we must order the custom fabric first.

Many of my clients from Europe and Canada ask for eco-friendly bags. This is a great selling point. We can use Recycled PU15 (made from recycled plastic) or Recycled Leather (made from leather scraps mixed with binder). But you need to know the reality. These materials are not sitting on the shelf. We have to order them specially for you.

This impacts your Lead Time16. Standard PU takes 15 days to get. Recycled PU15 might take 30 to 40 days. The mill needs to collect the waste and process it. Also, the cost is higher. The processing is expensive. You also pay for the certification tags. If you want a "Recycled" hangtag, we need to provide proof. This adds cost. However, for some brands, this story justifies a higher retail price. If you have the budget and the time, it is a good option. If you are in a rush, stick to standard materials.

Can You Support Compliance for US/EU Markets?

Customs will seize your goods if they contain banned chemicals. You need to ensure the materials meet Western standards for safety and toxicity.

Yes, both leather and PU must pass tests like REACH (Europe) or CA65 (USA). Leather must be free of Chromium VI17. PU must be free of Phthalates and heavy metals. We only buy materials from certified mills to ensure you pass customs.

Compliance is not optional. It is the law. In California, Proposition 65 is very strict. It limits lead and phthalates18. Phthalates are chemicals used to make plastic soft. Cheap PU is full of them. If you buy the cheapest bag, you will fail this test. You could face huge fines or lawsuits.

Leather has different risks. The tanning process uses Chromium. If the factory does it wrong, it creates Chromium VI17. This causes skin allergies. It is banned in the EU. At Coraggio, we do not buy material from the street market. We buy from big mills that test their water and chemicals. We can send samples to SGS or Intertek for you. It costs a fe

Understanding bulk-order dynamics helps you set realistic pricing, manage risk, and negotiate better with factories and wholesalers. ↩

Speeding up production while keeping quality stable boosts your margins and makes your supply chain more reliable. ↩

Learning how high-end markets work lets you justify premium pricing and design products that truly match luxury expectations. ↩

Clarifying your target demographic helps you choose the right material, style, and price point so products actually sell. ↩

Seeing how materials run on a production line reveals hidden costs, lead-time issues, and quality risks before you place orders. ↩

Comparing water resistance helps you choose materials that perform well in real-life use and reduce returns and complaints. ↩

Understanding hydrolysis helps you spec better PU and avoid embarrassing product failures after a season of use. ↩

Designing true legacy products builds brand loyalty and lets you charge more for durable, long-lasting items. ↩

Knowing landed cost accurately prevents margin surprises and helps you price your products correctly from day one. ↩

Mastering MOQ helps you manage cash flow, avoid overstock, and still get competitive prices from suppliers. ↩

Choosing the right logo method elevates your brand image and makes your bags look more premium on the shelf. ↩

Screen printing can showcase complex logos cost-effectively; understanding its limits avoids fading or poor finishes. ↩

Aligning with fast fashion cycles helps you select materials and lead times that match trend-driven buying behavior. ↩

A solid pre-shipment inspection process reduces defects, returns, and negative reviews before goods leave the factory. ↩

Exploring Recycled PU helps you tap into sustainability trends and win eco-conscious customers without redesigning everything. ↩

Understanding lead time drivers helps you plan launches, avoid stock-outs, and coordinate marketing with deliveries. ↩

Knowing Chromium VI risks protects you from customs seizures, fines, and reputational damage in US/EU markets. ↩

Learning about phthalates ensures your PU products meet safety laws and keeps your brand off regulatory blacklists. ↩